THK's LM Guide SRN-G/SRN-GSLR Series represents a significant advancement in linear motion technology, engineered specifically for applications demanding ultra-high rigidity and a low center of gravity. This full roller-type LM Guide utilizes cylindrical rollers as the rolling elements, which are arranged in a precise, optimized configuration to maximize load capacity and stiffness. The design features a unique gothic arch groove raceway profile that ensures continuous line contact between the rollers and the raceway, distributing loads more evenly and significantly enhancing rigidity compared to traditional ball-based systems. The compact, low-profile structure of the SRN-G/SRN-GSLR Series lowers the center of gravity of the entire motion system, contributing to improved stability and reduced vibration during operation.

Key technical features include an exceptionally high rigidity rating, achieved through the full roller design and robust housing construction that minimizes elastic deformation under heavy loads. The series offers high load capacities in all directions—radial, reverse-radial, and lateral—making it suitable for complex loading conditions. Preload adjustments are available to eliminate internal clearance, further boosting rigidity and ensuring precise, backlash-free motion. Additionally, the LM Guide is designed for smooth, quiet operation with low friction, even at high speeds, and incorporates effective sealing mechanisms to protect against contaminants like dust and chips, thereby extending service life in harsh environments.

Performance advantages are substantial, starting with unparalleled positioning accuracy and repeatability, critical for precision tasks. The ultra-high rigidity minimizes deflection under load, maintaining alignment and ensuring consistent performance in high-stress applications. This results in improved machining quality, higher throughput, and reduced downtime. The low center of gravity enhances dynamic stability, reducing the risk of tipping or oscillation during rapid acceleration and deceleration. Energy efficiency is another benefit, as the low friction design reduces power consumption and heat generation, contributing to lower operating costs.

Typical applications span a wide range of industries where precision, rigidity, and reliability are paramount. In industrial machinery, the SRN-G/SRN-GSLR Series is ideal for heavy-duty CNC machining centers, grinding machines, and milling equipment, where it supports high-load cutting forces and ensures precise tool paths. In automotive systems, it is employed in robotic welding arms, assembly line transporters, and precision testing equipment, providing the durability needed for continuous operation in demanding environments. For precision equipment, this LM Guide finds use in semiconductor manufacturing devices, optical positioning systems, and medical imaging apparatus, where its stability and accuracy enable micron-level positioning. Its robust design also makes it suitable for aerospace applications, such as actuator systems and calibration fixtures, where reliability under extreme conditions is essential. Overall, the THK LM Guide SRN-G/SRN-GSLR Series delivers a combination of strength, precision, and longevity that meets the rigorous demands of modern automation and precision engineering.

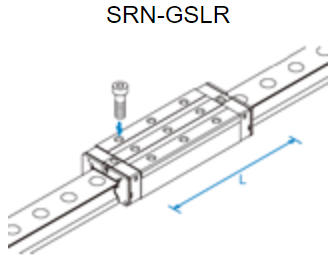

THK's LM Guide SRN/G Series represents a significant advancement in linear motion technology through its full roller-type design, delivering ultra-high rigidity and a low center of gravity ideal for demanding industrial applications. This series, including the SRN, SRN-G, and SRN-GSLC models, incorporates precision-engineered cylindrical rollers arranged in a full complement configuration between the rail and block. This design maximizes contact area and load distribution, substantially increasing rigidity while lowering the center of gravity to enhance stability under heavy loads and high moment conditions. The rollers are meticulously guided by a patented retainer system that ensures smooth, continuous circulation without slippage or skewing, even at high speeds, reducing vibration and noise for quieter operation.

Key technical features include a compact, low-profile structure that saves space in machinery layouts, alongside exceptional resistance to deformation under load. The SRN-GSLC variant further optimizes performance with a sealed, lubricated unit that extends maintenance intervals by retaining grease and excluding contaminants like dust, chips, and moisture. This series supports high load capacities in all directions—radial, reverse-radial, and lateral—with rated loads exceeding those of traditional ball-based guides by up to 50%, making it suitable for applications involving significant shock or varying force vectors. Precision grinding of the raceway surfaces ensures consistent accuracy and smooth motion, with running parallelism maintained within tight tolerances to support repetitive positioning tasks.

Performance advantages are evident in enhanced machine productivity and longevity. The ultra-high rigidity minimizes deflection during cutting, milling, or pressing operations, improving machining accuracy and surface finish quality. Low friction from the roller design reduces heat generation and energy consumption, while the low center of gravity contributes to system stability, reducing the risk of tipping or vibration-induced errors. These attributes lead to higher operational speeds, accelerated cycle times, and reduced downtime for maintenance, particularly in environments where reliability is critical.

Typical applications span industrial machinery, automotive systems, and precision equipment. In industrial automation, the SRN Series is deployed in CNC machining centers for tool changers and spindle supports, where rigidity ensures precise cutting paths. It also serves in heavy-duty press feeds, injection molding machines for platen movement, and semiconductor manufacturing equipment requiring vibration dampening. Within the automotive sector, these guides are integral to robotic welding arms, assembly line transfer systems, and engine component testing rigs that demand high moment resistance. For precision equipment, applications include coordinate measuring machines (CMMs), optical positioning stages, and medical device actuators where smooth, accurate motion is essential. By combining robustness with precision, THK's SRN/G Series enables innovations across industries, supporting everything from mass production to high-accuracy scientific instrumentation.

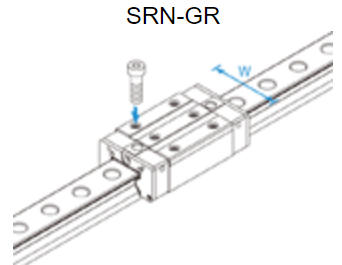

THK's LM Guide SRN/GR/SER full roller type linear motion systems represent a significant advancement in high-rigidity, precision guidance technology. Engineered with a unique full roller recirculation mechanism, these guides utilize cylindrical rollers instead of balls, distributing load across a larger contact area. This design inherently provides ultra-high rigidity and a notably low center of gravity, making the system exceptionally stable and resistant to moment loads. The series includes the SRN (standard type), SRN-G (with a grease reservoir for extended lubrication intervals), and SER (a wide, high-rigidity variant), offering tailored solutions for diverse application demands.

The core technical features of this series are centered on its roller-based architecture. The cylindrical rollers are precision-ground to ensure uniform load distribution and smooth, consistent motion. The incorporation of a low center of gravity design lowers the profile of the guide block, significantly enhancing its resistance to overturning moments and vibration. This is further complemented by optimized raceway geometry that maximizes the contact area between the rollers and the raceway, translating directly into higher load capacities and superior stiffness. For the SRN-G model, an integrated grease reservoir system is a key feature, which automatically supplies lubricant to the rolling elements, drastically reducing maintenance frequency and ensuring long-term, reliable operation even in harsh environments.

Performance advantages are substantial and multifaceted. The ultra-high rigidity minimizes elastic deformation under load, which is critical for maintaining positional accuracy and repeatability in high-precision machining and assembly processes. The low center of gravity and high moment rigidity ensure exceptional stability during high-speed, high-acceleration movements, preventing chatter and deflection. This results in improved machining surface finishes, higher product quality, and the ability to sustain heavier workloads. The full roller design also contributes to a longer service life compared to ball-based systems under equivalent load conditions, as the contact stresses are more favorably distributed. The extended lubrication intervals of the SRN-G model reduce total cost of ownership by minimizing downtime and lubricant consumption.

Typical applications for these robust linear guides are found in demanding sectors where precision, heavy loads, and high rigidity are non-negotiable. In industrial machinery, they are indispensable in heavy-duty machining centers, high-precision grinders, and injection molding machines, where they provide the stable foundation for slides and tables. Within the automotive industry, they are deployed in automated welding systems, large stamping presses, and precision assembly robots that handle heavy components. In the realm of precision equipment, these guides facilitate accurate motion in semiconductor manufacturing apparatus, precision measuring instruments, and advanced optical alignment systems, where minimal deflection and supreme stability are paramount for micron-level accuracy.

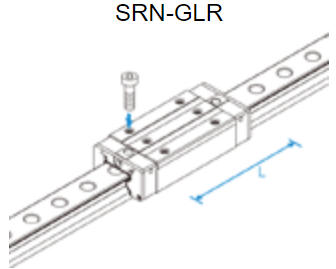

THK’s LM Guide SRN-G/SRN-GLR/SER full roller type linear motion systems redefine high rigidity and precision in demanding industrial applications. Engineered with a unique full roller recirculation mechanism, these guides employ cylindrical rollers arranged in a compact, low-profile design that significantly lowers the center of gravity. This configuration enhances moment rigidity and load capacity while maintaining smooth, precise linear motion. The series features a rigid, one-piece track rail and a compact block that integrates the roller retainer, ensuring exceptional stability and durability under heavy loads and high moment conditions.

Key technical features include the full roller recirculation system, which minimizes friction and delivers high positional accuracy. The low center of gravity design improves resistance to overturning moments, making the system ideal for applications subject to significant side loads or vibrations. With precision-ground raceways and optimized roller contact, the SRN-G/SRN-GLR/SER series achieves ultra-high rigidity—up to twice that of conventional ball-based LM guides—while maintaining low noise and minimal maintenance requirements. The series is available in various accuracy grades and preload options, allowing customization for specific performance needs, and includes seals and wipers to protect against contaminants in harsh environments.

Performance advantages are evident in the system’s ability to sustain high loads with minimal deformation, ensuring long-term accuracy and reliability. The full roller design distributes loads evenly across a larger contact area, reducing wear and extending service life even under continuous operation. This results in improved dynamic response, reduced vibration, and enhanced machining or positioning precision. Additionally, the low center of gravity contributes to system stability, reducing the risk of deflection in high-speed or heavy-duty applications.

Typical applications span industrial machinery, automotive systems, and precision equipment where rigidity and accuracy are paramount. In industrial automation, these LM guides are used in CNC machining centers, grinding machines, and heavy-duty transfer systems to support high-precision cutting and material handling. The automotive industry employs them in robotic welding arms, assembly line positioning units, and test equipment that demand repeatable motion under variable loads. For precision equipment, the SRN-G/SRN-GLR/SER series is integral to semiconductor manufacturing devices, optical alignment systems, and medical imaging equipment, where stability and minimal deflection are critical to operational success. By combining ultra-high rigidity with a low center of gravity, THK’s full roller type LM guides provide a robust solution for applications requiring uncompromising performance and durability.

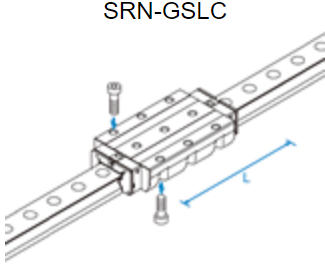

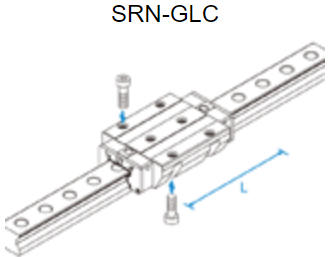

THK's LM Guide SRN-G/SRN-GLC Series represents a significant advancement in linear motion technology, featuring a full roller-type design that delivers exceptional rigidity and stability for demanding industrial applications. This ultra-high rigidity system is engineered with a low center of gravity, optimizing load distribution and minimizing deflection under heavy loads or high moment forces. The series incorporates precision-ground raceways and cylindrical rollers arranged in a full-complement configuration, ensuring smooth, nearly frictionless motion with minimal vibration and noise. Key technical features include an optimized sealing system that effectively excludes contaminants like dust, chips, and moisture while retaining lubrication, significantly extending service life even in harsh environments. The compact, low-profile design of the SRN-G/SRN-GLC Series allows for space-saving integration into machinery without compromising performance, while the standardized mounting dimensions facilitate easy retrofitting or replacement in existing systems.

Performance advantages of this series are substantial, starting with its ability to achieve positioning accuracy within microns, making it ideal for applications requiring repeatable precision. The full roller construction provides up to 300% higher load capacity compared to similarly sized ball-based guides, alongside a dramatic increase in rigidity that reduces elastic deformation under load by over 50%. This results in improved machining accuracy, reduced settling times, and enhanced surface finish quality in manufacturing processes. The low center of gravity design enhances stability during high-speed operation, preventing lift-off or vibration-induced errors while allowing for accelerated motion profiles without sacrificing precision. Maintenance requirements are minimized due to the efficient sealing and long-term lubrication retention, contributing to higher machine uptime and reduced total cost of ownership. Additionally, the series operates effectively across a wide temperature range and is available in various accuracy grades and preload levels to match specific application demands.

Typical applications span multiple industries where precision, rigidity, and reliability are paramount. In industrial machinery, the SRN-G/SRN-GLC Series is deployed in high-precision machining centers for slide units, heavy-duty grinding machines for workpiece positioning, and semiconductor manufacturing equipment requiring vibration-free motion. The automotive sector utilizes these guides in robotic welding arms, automated assembly lines for engine components, and precision testing equipment for quality control. Within precision equipment, they are found in optical measuring instruments, medical device manufacturing systems, and electronic component placement machines where sub-micron accuracy is critical. The series also serves effectively in packaging machinery, printing presses, and aerospace manufacturing tools, demonstrating its versatility across environments ranging from clean rooms to heavily contaminated workshop floors. By combining ultra-high rigidity with a low center of gravity and full roller construction, THK's SRN-G/SRN-GLC Series provides engineers with a robust linear motion solution that enhances machine performance while reducing lifecycle costs.

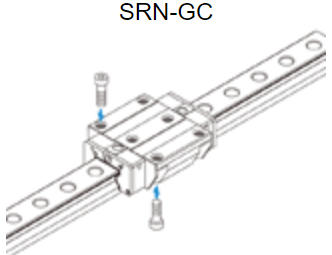

THK's LM Guide SRN-G/SRN-GC/SER Series represents a significant advancement in linear motion technology through its full roller type design, delivering ultra-high rigidity and an exceptionally low center of gravity. This series is engineered to meet the demanding requirements of modern industrial applications where precision, stability, and durability are non-negotiable. By incorporating a full complement of cylindrical rollers in the guide mechanism, these LM Guides achieve smooth, high-precision linear motion with minimal friction, making them ideal for heavy-load and high-moment applications.

Key technical features of the SRN-G/SRN-GC/SER Series include its robust construction, which ensures superior rigidity and resistance to deformation under load. The low center of gravity design enhances stability, reducing vibration and improving positional accuracy during operation. The full roller configuration allows for higher load capacities and longer service life compared to traditional ball-based guides, as rollers distribute loads more evenly and reduce stress concentrations. Additionally, the series offers options for sealed and lubricated units (such as the SRN-GC model), which provide excellent contamination resistance and maintenance-free operation in harsh environments. Pre-loaded versions are available to eliminate backlash, ensuring repeatable precision in high-accuracy tasks.

Performance advantages of these LM Guides are evident in their ability to handle extreme loads while maintaining smooth motion and minimal deflection. The ultra-high rigidity translates to improved machining accuracy and surface finish in applications like CNC machining centers, where tool path precision is critical. The low center of gravity minimizes tipping moments, enhancing safety and reliability in automated systems. With low friction coefficients and optimized roller geometries, the series also contributes to energy efficiency by reducing power consumption and heat generation. This makes it suitable for high-speed operations without compromising on lifespan or performance consistency.

Typical applications span across various sectors, including industrial machinery, where these guides are used in heavy-duty milling machines, grinding equipment, and transfer lines to ensure precise workpiece positioning and tool movement. In automotive systems, they facilitate accurate assembly processes, such as in robotic welding arms or engine component handling, where rigidity and repeatability are essential for quality control. Precision equipment, such as semiconductor manufacturing tools and optical alignment devices, benefits from the series' low vibration and high-accuracy capabilities, enabling micron-level positioning in cleanroom environments. Overall, the THK LM Guide SRN-G/SRN-GC/SER Series provides a reliable, high-performance solution for applications demanding robust linear motion with uncompromising rigidity and stability.