TIMKEN Thrust Spherical Roller Bearings (Type TSR) represent a pinnacle of engineering excellence, designed to handle extreme axial loads, misalignment, and harsh operating conditions with unmatched reliability. As a leader in advanced bearing technology, TIMKEN has developed these bearings to deliver superior performance in demanding industrial, automotive, and heavy machinery applications where high thrust capacity and durability are critical.

When it comes to handling high axial loads with precision and reliability, **TIMKEN Thrust Cylindrical Roller Bearings (Type TP)** stand out as a superior solution for demanding industrial and automotive applications. Designed to accommodate heavy thrust loads in one direction while maintaining smooth operation, these bearings are a critical component in machinery where axial force resistance, durability, and efficiency are paramount.

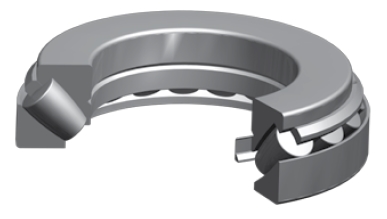

When it comes to handling high axial loads and demanding operating conditions, TIMKEN Thrust Bearings—particularly Thrust Tapered Roller Bearings—stand out as a premier solution for industrial, automotive, and precision applications. Designed with advanced engineering and superior materials, these bearings deliver unmatched durability, efficiency, and reliability in environments where thrust load management is critical.