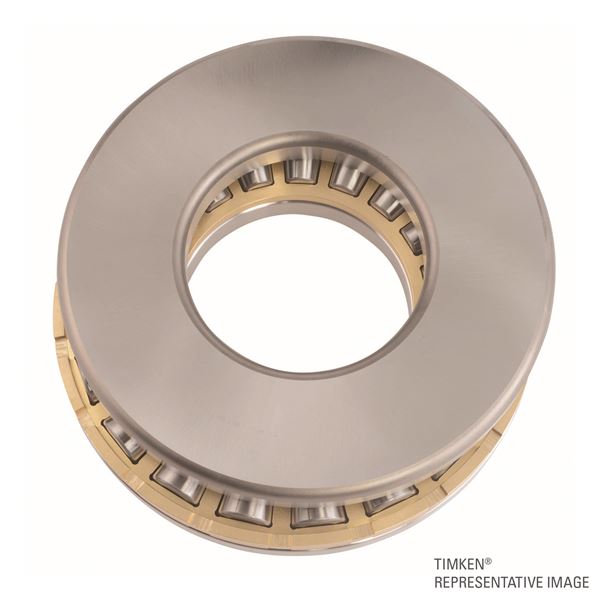

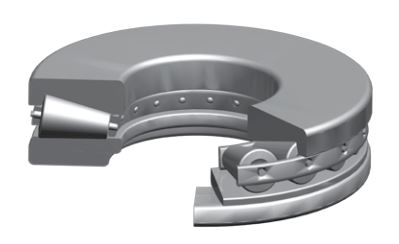

When it comes to handling high axial loads with precision and durability, **TIMKEN Thrust Tapered Roller Bearings Type TTHD** stand out as a superior solution for demanding industrial and automotive applications. Designed with advanced engineering and high-quality steel, these bearings deliver unmatched reliability in environments where heavy thrust loads, shock resistance, and long service life are critical.

TIMKEN thrust tapered roller bearings, specifically the **Type TTHDFL V Flat** series, represent a pinnacle of engineering excellence designed to handle extreme axial loads and demanding operating conditions. These high-performance bearings combine robust construction with precision design, making them indispensable in applications where reliability, durability, and efficiency are critical.

TIMKEN thrust bearings, particularly the **Thrust Tapered Roller Bearings Type TTHDFLSA**, represent a pinnacle of engineering excellence designed to handle heavy axial loads while maintaining precision and durability in demanding applications. These bearings are engineered with advanced materials, optimized geometries, and superior heat treatment processes to deliver unmatched performance in industrial machinery, automotive systems, and precision equipment.

TIMKEN, a global leader in engineered bearings and mechanical power transmission solutions, offers a robust range of **Thrust Tapered Roller Bearings (Type TTSP, TTSPS, TTSPL)** designed to handle extreme axial loads while maintaining precision and durability in demanding applications. These specialized bearings are engineered to deliver superior performance in industries where high thrust capacity, rigidity, and reliability are critical—such as heavy industrial machinery, automotive systems, and precision equipment.

TIMKEN is a global leader in engineered bearings and mechanical power transmission products, renowned for delivering reliability, durability, and precision in the most demanding industrial and automotive applications. Among its extensive portfolio, **TIMKEN Thrust Tapered Roller Bearings (Type TTC, TTCS, and TTCL)** stand out as high-performance solutions designed to handle heavy axial loads while accommodating moderate radial loads. These bearings are engineered to excel in applications where space constraints, high thrust capacity, and long service life are critical.