THK's DC and DCM Series lead screw nuts represent a significant advancement in precision linear motion technology, engineered to deliver exceptional performance in demanding industrial applications. These components form the core of highly efficient motion control systems, converting rotational movement into precise linear displacement with remarkable accuracy and reliability. The series encompasses both standard (DC) and miniature (DCM) configurations, providing design flexibility across a broad spectrum of machinery requirements while maintaining THK's renowned quality standards.

The technical sophistication of these lead screw nuts begins with their precision-ground screw shafts, manufactured to exacting tolerances that ensure minimal backlash and consistent positioning accuracy. The nuts incorporate THK's proprietary ball circulation system, where precision-grade balls roll smoothly between the screw shaft and nut body through precisely engineered return guides. This optimized circulation path minimizes friction while maintaining constant ball contact, resulting in smooth motion characteristics and extended service life. The series features preloading mechanisms that eliminate axial play, delivering high rigidity and precise motion repetition critical for precision applications. Special sealing systems protect the internal ball tracks from contaminants while retaining lubrication, significantly enhancing operational reliability in harsh environments.

Performance advantages of the DC and DCM Series translate directly into operational benefits across multiple dimensions. These components achieve positioning accuracy within micrometers, maintaining this precision throughout their extended service life due to minimal wear characteristics. The efficient ball recirculation design provides high mechanical efficiency typically exceeding 90%, enabling smaller drive motors and reducing overall system energy consumption. High rigidity allows these nuts to withstand substantial axial loads while maintaining positional stability, with dynamic load ratings optimized for long-term continuous operation. The compact design of the DCM miniature variants particularly benefits space-constrained applications without compromising performance capabilities.

Industrial machinery applications extensively utilize these lead screw nuts in CNC machining centers for precise tool positioning, semiconductor manufacturing equipment requiring sub-micron accuracy, and automated assembly systems demanding high-speed precision motion. In automotive manufacturing, they drive precision in robotic welding arms, automate component placement in assembly lines, and control positioning in quality inspection stations. Precision equipment implementations include medical device manufacturing systems, optical alignment apparatus, and laboratory automation where vibration-free smooth motion is paramount. The series' reliability and precision make it particularly valuable in applications where maintenance access is limited or where consistent performance directly impacts production quality and throughput.

The DC and DCM Series' combination of precision engineering, robust construction, and application versatility establishes them as premier solutions for engineers designing next-generation industrial automation, advanced manufacturing systems, and high-precision equipment across multiple sectors.

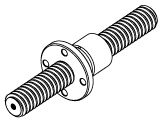

The THK DC Series lead screw nut represents a precision-engineered solution for converting rotary motion into linear movement with exceptional accuracy and reliability. Featuring a compact design with integrated ball recirculation, this model delivers smooth, low-friction operation while maintaining high rigidity and positioning repeatability. Its construction incorporates precision-ground threads and optimized ball groove geometry to minimize backlash and ensure consistent torque transmission across the entire travel length.

Key technical features include a preloaded nut design that eliminates axial play, resulting in precise positional accuracy even under varying load conditions. The DC Series utilizes high-grade bearing steel for both the screw shaft and nut, hardened to HRC 58-62 for superior wear resistance and long service life. Special sealing mechanisms effectively prevent contamination from dust, chips, and other particulates, making these components suitable for demanding environments. The series offers multiple accuracy grades and lead options to match specific application requirements, with standard leads ranging from 1mm to 40mm depending on model size.

Performance advantages stem from THK's proprietary manufacturing techniques, which ensure exceptional straightness and lead accuracy. The DC Series demonstrates minimal thermal expansion characteristics, maintaining precision across temperature variations common in industrial settings. With efficiency ratings exceeding 90%, these lead screw nuts convert most input torque into useful linear force, reducing energy consumption compared to alternative motion systems. Their quiet operation at high speeds—achieving linear velocities up to 3 m/s in some configurations—makes them ideal for noise-sensitive applications. The design's high stiffness enables rapid acceleration and deceleration while maintaining positioning stability, with dynamic load capacities reaching 15,000 N in larger models.

In industrial machinery applications, DC Series components frequently appear in CNC machining centers for tool positioning, automated assembly systems for precise part placement, and semiconductor manufacturing equipment requiring sub-micron accuracy. The automotive industry employs these lead screw nuts in electric power steering systems, transmission testing equipment, and robotic welding cells where reliability and precision are paramount. For precision equipment, they serve critical functions in medical imaging devices, coordinate measuring machines, and optical positioning systems where smooth motion and minimal vibration are essential. The series' versatility also extends to packaging machinery, printing presses, and aerospace testing apparatus, demonstrating their adaptability across diverse technological fields requiring controlled linear motion.