THK's LM Guide Caged Ball LM Guide Global Standard size Model SHS SHS LR SERIES represents a significant advancement in linear motion technology, engineered to deliver exceptional precision, durability, and reliability in demanding industrial environments. This series incorporates a unique caged ball design, where precision balls are retained and separated by a polymer cage, effectively minimizing friction, reducing heat generation, and eliminating metal-to-metal contact between the balls. This design not only enhances operational smoothness but also substantially extends the service life of the guide by preventing ball-to-ball abrasion and reducing the need for frequent lubrication.

Key technical features of the SHS SHS LR SERIES include its global standard dimensions, ensuring full interchangeability and easy integration with existing machinery and competing products that adhere to the same specifications. The series is constructed from high-carbon chromium bearing steel, heat-treated to achieve an optimal balance of hardness and toughness, providing superior load capacity and resistance to wear and deformation. The LM guides are available in various accuracy grades, from high-precision to super-precision, catering to diverse application requirements. Additionally, the incorporation of seals and scrapers at both ends effectively shields the internal components from contaminants such as dust, chips, and moisture, maintaining performance integrity even in harsh operating conditions.

Performance advantages are evident in the series' ability to handle high loads—both radial and moment—with remarkable stability and minimal deformation. The caged ball mechanism ensures consistent motion characteristics, reducing vibration and noise levels, which is critical for high-speed applications. This results in improved positional accuracy, repeatability, and overall efficiency of automated systems. The reduced friction coefficient translates into lower driving force requirements, enabling energy savings and allowing for the use of smaller, more cost-effective drive components. Maintenance intervals are extended due to the optimized lubrication retention and contaminant exclusion, lowering total cost of ownership over the system's lifecycle.

Typical applications span a wide range of industries, leveraging the robustness and precision of the SHS SHS LR SERIES. In industrial machinery, these guides are integral to CNC machining centers, where they facilitate precise tool positioning and high-speed axis movements, directly impacting machining accuracy and surface finish quality. Within automotive manufacturing systems, they are employed in robotic welding arms, assembly line transporters, and automated inspection equipment, ensuring reliable performance under continuous, high-cycle operations. In the realm of precision equipment, the series finds use in semiconductor manufacturing apparatus, medical device automation, and optical alignment systems, where micron-level accuracy and contamination control are paramount. By offering a reliable, high-performance solution, the THK SHS SHS LR SERIES enables manufacturers to enhance productivity, improve product quality, and achieve greater operational efficiency across various sectors.

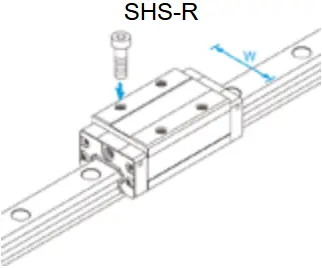

The THK LM Guide Caged Ball LM Guide Global Standard size Model SHS/SHS R SERIES represents a fundamental advancement in linear motion technology, engineered for high-load capacity, exceptional rigidity, and sustained precision in demanding industrial environments. This series utilizes a unique caged ball retainer system that fundamentally transforms performance and reliability. Unlike conventional linear guides where balls can contact each other during motion, the precision-engineered polymer cage separates each recirculating steel ball. This design eliminates ball-to-ball contact, drastically reducing friction, heat generation, and wear. The result is a smoother, quieter operation with significantly lower torque fluctuations and a dramatic extension in service life, even under high-speed or high-frequency reciprocating motions.

Key technical features define the superiority of the SHS/SHS R SERIES. The global standard size ensures full interchangeability and easy integration into existing machinery and new designs worldwide, simplifying procurement and inventory management. The guide rails and blocks are manufactured from high-carbon chromium bearing steel, heat-treated to a core hardness of HRC 58-64, providing exceptional resistance to denting and wear. The caged ball design not only enhances longevity but also allows for more efficient and consistent lubrication, as grease is retained within the cage structure. The SHS R variant often incorporates a rubber seal on the end face for added protection against contaminants. Four rows of balls arranged in a Gothic arch structure provide an optimal load-bearing configuration, enabling the guide to withstand heavy loads in all directions—radial, reverse-radial, and lateral.

The performance advantages are substantial for end-users. The primary benefit is unparalleled operational smoothness and positional accuracy, which is critical for precision machining and automated assembly processes. The reduced friction directly translates to lower driving force requirements, allowing for the use of smaller, more energy-efficient motors and drives. Maintenance intervals are extended due to the efficient lubrication and contaminant-resistant designs, minimizing machine downtime and total cost of ownership. The high rigidity ensures minimal deflection under load, guaranteeing repeatable accuracy and protecting sensitive tooling or components from misalignment.

Typical applications for the SHS/SHS R SERIES are found across industries where reliability and precision are non-negotiable. In industrial machinery, they are the backbone of CNC machining centers, grinding machines, and high-speed milling equipment, providing the stable and precise movement for cutting tools and worktables. Within automotive manufacturing systems, these guides are integral to robotic welding arms, precision assembly robots, and automated material handling systems on production lines. In the realm of precision equipment, they enable the exacting movements required in semiconductor manufacturing apparatus, optical positioning stages, and coordinate measuring machines (CMMs), where nanometer-level accuracy is paramount.

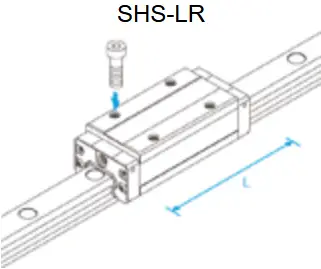

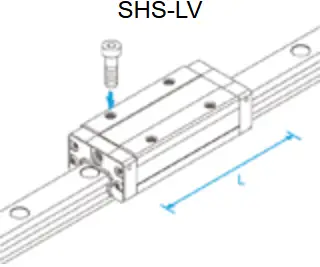

The THK LM Guide Caged Ball LM Guide Global Standard size Model SHS and SHS LV SERIES represents a significant advancement in linear motion technology, engineered to deliver unparalleled precision, rigidity, and longevity in demanding industrial environments. These guides incorporate a unique caged ball design where precision-engineered balls are retained and separated by a polymer cage, effectively eliminating metal-to-metal contact between the balls during operation. This design drastically reduces friction, heat generation, and torque variation, while simultaneously preventing ball-to-ball abrasion that can lead to premature wear and failure. The SHS series features a standard height profile, whereas the SHS LV (Low Version) series offers a reduced height, providing critical design flexibility for applications with strict space constraints without sacrificing performance.

Key technical features of the SHS/SHS LV series are centered on their robust construction and optimized geometry. The raceway grooves are precision-ground to a Gothic arch profile, ensuring a high degree of contact with the balls for increased load capacity and smoother motion. The integrated caged ball retainer not only minimizes friction but also allows for significantly higher maximum speeds compared to conventional non-caged designs. For lubrication and maintenance, these guides are equipped with advanced lubrication units, including optional grease nipples or centralized lubrication ports, ensuring a consistent lubricant film is maintained to protect against wear and corrosion. The global standard size ensures full interchangeability with other equivalent products, simplifying machine design, procurement, and maintenance on a worldwide scale.

The performance advantages are substantial and directly address the core challenges in automation and precision machinery. The caged ball system results in a dramatic increase in operational life, often by a factor of two or more, by eliminating a primary cause of wear. The consistent, low-friction motion ensures exceptional positional accuracy and repeatability, which is critical for processes like CNC machining, laser cutting, and precision assembly. The high rigidity of the block and rail assembly allows for high moment load capacities, enabling stable performance even under heavy cutting forces or off-center loads. Furthermore, the low friction characteristic contributes to lower power consumption for driving actuators, enhancing the overall energy efficiency of the machine.

Typical applications for the THK SHS and SHS LV SERIES are found across a broad spectrum of high-performance industries. In industrial machinery, they are the driving force behind the accuracy of machine tools, including machining centers, grinding machines, and milling machines, where they guide tooling and worktables with micron-level precision. Within automotive manufacturing systems, these guides are integral to robotic welding arms, precision assembly robots, and automated material handling equipment, providing the speed and durability required for high-cycle production lines. In the realm of precision equipment, they are indispensable in semiconductor manufacturing apparatus, such as wafer steppers and probe handlers, electronic component assembly machines, and high-speed pick-and-place systems, where flawless, repeatable linear motion is non-negotiable for product quality and yield.

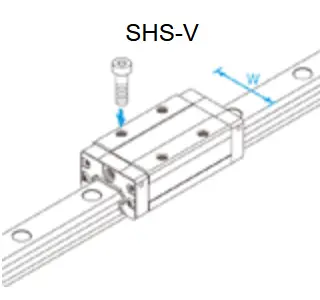

THK's LM Guide Caged Ball LM Guide Global Standard size Model SHS SHS V SERIES represents a significant advancement in linear motion technology, engineered to deliver exceptional precision, durability, and reliability in demanding industrial environments. This series incorporates a unique caged ball design where the rolling elements are separated and guided by a precision-engineered retainer, effectively minimizing friction, reducing heat generation, and preventing metal-to-metal contact between the balls. The SHS V models are built to global standard dimensions, ensuring seamless interchangeability and integration with existing machinery and competitor products, which simplifies procurement, inventory management, and system upgrades for engineers and maintenance teams worldwide.

Key technical features of the SHS SHS V SERIES include a robust structure with four-way equal load capacity, allowing it to handle radial, reverse-radial, and lateral loads simultaneously with high rigidity. The ball retainer, a defining component, ensures smooth, consistent motion by maintaining precise ball-to-ball spacing, which eliminates friction and noise while enhancing operational stability at high speeds. The guide rails and blocks are manufactured from high-carbon chromium bearing steel, heat-treated to achieve a surface hardness of 58-64 HRC, providing exceptional wear resistance and long service life. Sealing systems are integrated to protect against contaminants such as dust, chips, and moisture, with options including metal and rubber seals for diverse environmental conditions. Pre-loaded ball configurations are available to eliminate backlash, ensuring high positional accuracy and repeatability, which is critical for precision applications.

Performance advantages of this series are substantial, starting with its ability to operate at higher speeds and accelerations than conventional linear guides, thanks to the reduced friction and heat buildup from the caged ball design. This results in lower maintenance requirements, extended lubrication intervals, and consistent performance over time, even under heavy loads and continuous operation. The global standard sizing ensures broad compatibility, reducing downtime during replacements or retrofits. Energy efficiency is another benefit, as the minimized friction translates to lower driving force requirements, which can lead to reduced power consumption in automated systems.

Typical applications for the THK SHS SHS V SERIES span across industries where precision and reliability are paramount. In industrial machinery, it is commonly used in CNC machining centers, milling machines, and grinding equipment to provide accurate table and spindle positioning. Within automotive systems, these guides are integral to robotic welding arms, assembly line transporters, and precision testing instruments, where they endure high-cycle operations and variable loads. In precision equipment, the series finds use in semiconductor manufacturing devices, optical positioning systems, and medical diagnostic machines, where smooth, vibration-free motion is essential for achieving micron-level accuracy. By combining innovative design with rigorous manufacturing standards, the SHS SHS V SERIES offers a dependable solution for enhancing the performance and longevity of linear motion systems in today's advanced technological landscape.

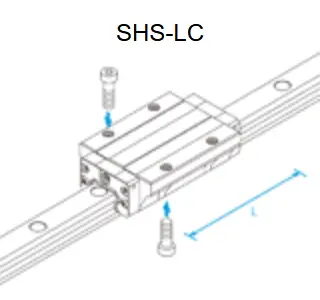

THK's LM Guide Caged Ball LM Guide Global Standard size Model SHS SHS LC SERIES represents a significant advancement in linear motion technology, engineered to deliver exceptional precision, durability, and reliability in demanding industrial environments. This series incorporates a unique caged ball design, where precision balls are retained and separated by a polymer cage, effectively minimizing friction, reducing heat generation, and eliminating metal-to-metal contact between the balls. This design not only extends the operational lifespan of the guide but also ensures smooth, consistent motion even under high-speed or high-load conditions. The SHS and SHS LC models are built to global standard dimensions, facilitating easy integration and interchangeability with existing systems worldwide, which simplifies procurement, inventory management, and maintenance for engineers and operators.

Key technical features of the SHS SHS LC SERIES include high load capacity, achieved through optimized raceway geometry and the use of high-grade steel, which enhances rigidity and withstands substantial moment loads. The caged ball mechanism prevents ball-to-ball friction, reducing noise and vibration while maintaining lubrication efficiency for long-term performance. Additionally, the series offers superior accuracy with minimal travel variation, thanks to precision grinding and stringent quality control during manufacturing. Sealing options are available to protect against contaminants like dust, chips, and moisture, making these guides suitable for harsh environments. The compact and lightweight design of the SHS LC variants further allows for space-saving installations without compromising on strength or functionality.

Performance advantages of this series are evident in its ability to support high-speed operations with minimal maintenance requirements, leading to increased productivity and reduced downtime in industrial settings. The caged ball design contributes to lower torque fluctuations and smoother acceleration, which is critical for applications requiring precise positioning and repeatability. Energy efficiency is another benefit, as the reduced friction translates to lower power consumption and less heat dissipation, contributing to overall system sustainability. These guides are designed for long service life, even under continuous or heavy-duty cycles, providing a cost-effective solution by minimizing replacement needs and associated labor costs.

Typical applications for the THK LM Guide Caged Ball SHS SHS LC SERIES span across various sectors, including industrial machinery where they are used in CNC machining centers, milling machines, and grinding equipment to ensure accurate tool positioning and smooth axis movements. In automotive systems, these guides facilitate precise operations in assembly robots, welding arms, and testing apparatus, enhancing manufacturing efficiency and product quality. For precision equipment, they are integral to semiconductor manufacturing devices, medical imaging systems, and optical instruments, where stability and minimal vibration are paramount. Overall, this series offers a robust, versatile solution for engineers seeking to optimize linear motion performance in diverse, high-stakes applications.

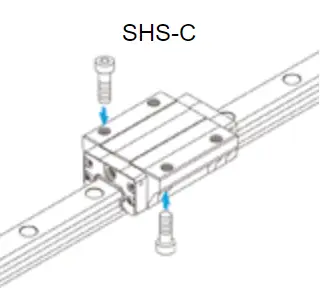

The THK LM Guide Caged Ball LM Guide Global Standard size Model SHS SHS C SERIES represents a significant advancement in linear motion technology, engineered to deliver exceptional precision, durability, and reliability in demanding industrial environments. This series incorporates a unique caged ball design, where precision-engineered balls are retained and guided by a polymer cage, effectively minimizing direct ball-to-ball contact and reducing friction, heat generation, and wear. Constructed from high-carbon chromium bearing steel, the raceways and balls are heat-treated to a core hardness of HRC 58-64, ensuring superior load capacity and long-term operational integrity. The SHS C SERIES is manufactured to global standard dimensions, facilitating seamless interchangeability and integration with existing machinery and competing products that adhere to these specifications, thereby simplifying design, procurement, and maintenance processes worldwide.

Key technical features of the SHS C SERIES include its four-way equal load capacity, allowing it to handle radial, reverse radial, and lateral loads simultaneously with high efficiency. The incorporation of the caged ball mechanism not only lowers friction but also enables higher maximum speeds and accelerations compared to conventional designs, as it prevents ball crowding and skidding at high velocities. End seals and side seals, made from advanced synthetic rubber, provide robust protection against contaminants such as dust, chips, and moisture, making these guides suitable for harsh operating conditions. For lubrication, the series features optimized grease retention and optional lubrication ports to ensure consistent performance and extend service intervals, reducing total cost of ownership.

Performance advantages are evident in its smooth, low-noise operation, which is critical for precision applications. The reduced friction translates to lower driving force requirements, enabling the use of smaller, more energy-efficient motors and drives. Its high rigidity and accuracy contribute to improved positioning repeatability, often within microns, which is essential for tasks requiring meticulous alignment and motion control. The durability of the components ensures minimal maintenance needs and extended service life, even under continuous heavy loads or in environments with significant vibration and shock.

Typical applications span across various high-performance sectors. In industrial machinery, the SHS C SERIES is widely used in CNC machining centers, grinding machines, and industrial robots where precision linear motion is paramount for manufacturing accuracy and efficiency. Within automotive systems, these guides are integral to automated assembly lines, robotic welding arms, and precision testing equipment, supporting high-speed production with reliability. In precision equipment, they find use in semiconductor manufacturing devices, medical imaging systems, and optical positioning stages, where smooth, contamination-resistant motion is crucial for achieving sub-micron level accuracy and maintaining sterile or cleanroom conditions.