The THK LM Guide Caged Ball LM Guide Miniature Model SRS/SRS WN SERIES represents a significant advancement in compact linear motion technology, engineered specifically for applications demanding high precision, reliability, and space efficiency. This series incorporates a unique caged ball design where precision steel balls are retained and guided by a resin cage within the LM block. This fundamental design eliminates ball-to-ball contact, drastically reducing friction, heat generation, and torque variation. The result is exceptionally smooth, quiet, and consistent linear motion, even at high speeds.

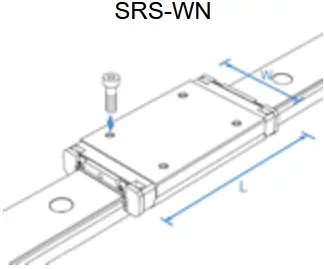

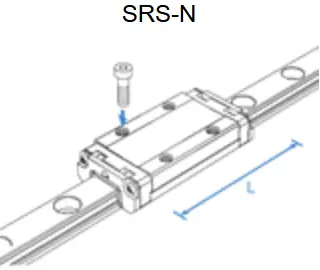

Key technical features define the performance envelope of the SRS/SRS WN series. Its compact and lightweight design is a primary characteristic, making it ideal for installations with severe space constraints. The incorporation of the caged ball mechanism is critical; it prevents the balls from falling out even when the LM block is removed from the track rail, simplifying assembly and maintenance. The series offers various configurations, including standard (SRS) and wide (SRS WN) models, with the wide version providing enhanced moment load capacity and rigidity. Sealing is another critical feature, with integrated seals designed to effectively exclude contaminants like dust and chips while retaining grease, thereby ensuring long-term operational reliability and reducing maintenance frequency.

The performance advantages derived from these features are substantial for modern automation. The reduction in friction directly translates to lower driving force requirements, enabling the use of smaller, more cost-effective motors and drives. The smooth motion profile minimizes vibration and noise, which is crucial for high-precision machining and quiet operating environments. The high rigidity and accuracy of the guide contribute to improved positioning repeatability and machining quality. Furthermore, the extended service life, a direct result of reduced wear and effective sealing, minimizes machine downtime and total cost of ownership.

Typical applications for the miniature SRS/SRS WN SERIES are found across industries where precision and compactness are paramount. In industrial machinery, they are extensively used in the drive units of precision assembly robots, the linear axes of compact CNC milling machines, and the positioning stages for laser processing equipment. Within the realm of automotive manufacturing, these guides are integral to components of automated welding arms, precision parts feeders, and inspection and measurement devices on production lines. In the field of precision equipment, they are the motion solution of choice for the sliding mechanisms in semiconductor manufacturing apparatus, the stages of medical diagnostic devices, and the moving parts within advanced optical and measuring instruments, where their quiet, clean, and jitter-free operation is essential.

THK's Caged Ball LM Guide Miniature Model SRS/SRN SERIES represents a significant advancement in compact linear motion technology, specifically engineered for applications where space constraints, precision, and reliability are paramount. These guides utilize a unique caged ball design where precision balls are securely held and separated by a resin retainer, effectively eliminating metal-to-metal contact between the balls. This fundamental design principle drastically reduces friction and heat generation while preventing the torque variations and uneven motion often associated with conventional ball-based linear guides.

The technical features of the SRS/SRN series are defined by their miniature cross-section and optimized internal geometry. The incorporation of the caged ball retainer is the cornerstone of its performance. By maintaining consistent ball-to-ball spacing, the retainer ensures smooth, uniform rolling motion with exceptionally low and stable friction coefficients. This design also allows for higher maximum speeds and accelerations compared to standard designs, as it mitigates the risk of ball skidding and slippage. The guides are constructed from high-carbon chromium bearing steel, heat-treated to achieve superior hardness and long-term wear resistance. They are available with various preload options, enabling engineers to fine-tune the system's rigidity and eliminate internal clearance for applications demanding the highest levels of positional accuracy. The SRN variant typically includes a dust seal to protect the critical rolling elements from contaminants, enhancing operational life in challenging environments.

Performance advantages are substantial and directly stem from the caged ball technology. The most notable benefit is the dramatic reduction in required driving force, often by 30% or more, leading to lower energy consumption and enabling the use of smaller, more cost-effective motors and drives. The consistent low friction results in exceptional smoothness of motion, critical for applications involving precise start-stop positioning or minute incremental movements. Furthermore, the elimination of ball-to-ball contact significantly reduces wear, extends service life, and minimizes the generation of vibration and noise. This makes the SRS/SRN series exceptionally quiet and reliable over extended operational periods.

Typical applications for these miniature guides are found across industries where precision and compactness are non-negotiable. In industrial machinery, they are integral to the function of high-speed chip mounters, precision assembly robots, and the linear axes of miniature CNC machining centers. Within the realm of automotive systems, they are employed in advanced manufacturing equipment for electronic component placement, fuel injection testing apparatus, and delicate sensor calibration stages. For precision equipment, the SRS/SRN series is the component of choice in optical instrument stages, medical diagnostic devices like DNA analyzers, semiconductor wafer inspection equipment, and various laboratory automation systems where flawless, repeatable motion is essential for data integrity and process reliability.

The THK LM Guide Caged Ball LM Guide Miniature Model SRS, SRS WM SERIES represents a significant advancement in compact linear motion technology, specifically engineered for applications where space constraints, precision, and reliability are paramount. This series incorporates a unique caged ball design, where precision steel balls are retained and guided by a polymer cage, effectively eliminating metal-to-metal contact between the balls. This fundamental design principle is the source of its exceptional performance characteristics, offering a robust solution for miniature automation and precision positioning systems.

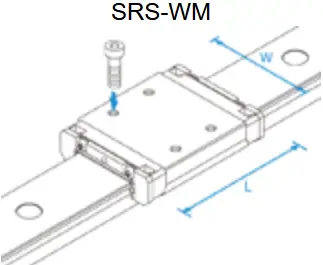

Technically, the SRS and SRS WM models are characterized by their compact cross-sectional dimensions and low profile. The caged ball mechanism is the core feature, providing several critical advantages. By separating the balls, it drastically reduces rotational torque and friction, leading to exceptionally smooth and stable motion. This design also prevents ball-to-ball contact, which minimizes heat generation, reduces wear, and virtually eliminates the need for lubrication. This makes the series exceptionally clean and suitable for environments where contamination from grease or oil is a concern, such as in cleanrooms, food processing, or pharmaceutical manufacturing. The WM variant typically indicates a wider rail and block, offering higher load capacities and improved moment rigidity compared to the standard SRS model, while still maintaining a miniature form factor.

The performance advantages of this series are substantial. The low friction directly translates to higher precision, repeatability, and energy efficiency. The reduced heat generation ensures consistent performance over long operational periods and extends the service life of the guide. Furthermore, the caged ball design offers outstanding vibration damping characteristics and operates with significantly less noise than conventional linear guides, which is critical in noise-sensitive laboratory or medical environments. Its maintenance-free or minimal-maintenance nature reduces total cost of ownership by eliminating downtime for re-lubrication.

Typical applications for the THK SRS and SRS WM SERIES are found across industries demanding high precision in a small footprint. In industrial machinery, they are integral to the precise movement of pick-and-place heads in electronic component assembly robots, the linear positioning in miniature CNC stages, and the actuation in semiconductor and LCD manufacturing equipment. Within automotive systems, these guides are employed in precision sensors, small valve actuators, and advanced driver-assistance system (ADAS) calibration equipment. In the realm of precision equipment, they are the motion solution of choice for laboratory automation, medical diagnostic devices, optical inspection systems, and high-accuracy measuring instruments, where their smooth, quiet, and contamination-free operation is indispensable for maintaining the integrity of sensitive processes.

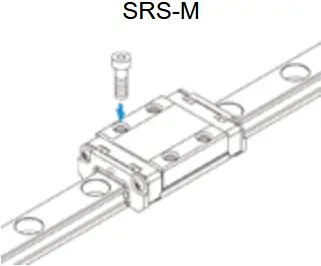

THK's LM Guide Caged Ball LM Guide Miniature Model SRS/SRS M SERIES represents a significant advancement in compact linear motion technology, specifically engineered for applications where space constraints and precision are paramount. These miniature guides incorporate a unique caged ball design where precision steel balls are retained and separated by a polymer cage. This configuration eliminates ball-to-ball contact, reducing friction, heat generation, and wear, while ensuring smooth, consistent motion with minimal variation in dynamic torque. The compact cross-section and lightweight construction of the SRS and SRS M models make them ideal for integration into tightly spaced assemblies without compromising on load capacity or rigidity.

Key technical features define the performance envelope of this series. The caged ball mechanism is fundamental, as it prevents torque fluctuations and minimizes the risk of ball smearing, even under high-speed or rapid reciprocating motions. The races are precision-ground from high-carbon chromium bearing steel, heat-treated to achieve optimal hardness and durability, providing excellent resistance to indentation and fatigue. For corrosion resistance in challenging environments, models with stainless steel components are available. The SRS M series often includes a built-in seal or wiper design to effectively exclude contaminants like dust, chips, and moisture, thereby protecting the rolling elements and extending service life. Pre-load options allow for the adjustment of internal clearance, enabling engineers to select a configuration that delivers high rigidity and minimal deflection under moment loads, which is critical for maintaining accuracy.

The performance advantages are substantial, directly impacting machine reliability and output quality. The primary benefit is a dramatic reduction in friction, which translates to lower driving force requirements, higher achievable speeds, and improved energy efficiency. The stability offered by the caged ball system results in exceptionally smooth and quiet operation, with minimal vibration, contributing to higher positioning accuracy and repeatability. This smooth motion profile also reduces the transmission of vibration to sensitive components elsewhere in the machine. The extended service life, a direct result of reduced wear and effective contamination protection, minimizes maintenance intervals and downtime, leading to a lower total cost of ownership.

Typical applications for the SRS/SRS M SERIES are found wherever precision, compactness, and reliability are demanded. In industrial automation, these guides are integral to the linear axes of high-speed pick-and-place robots, miniature Cartesian gantry systems, and the precise positioning stages within semiconductor and electronics manufacturing equipment. Within the automotive sector, they are employed in advanced manufacturing processes, such as the articulated arms of laser welding and cutting robots, precision fixturing for assembly, and sensitive measurement and inspection probes. In the realm of precision equipment, these miniature guides are the driving force behind the smooth motion in medical devices like DNA analyzers and automated sample handlers, as well as in optical and photonic alignment systems, where sub-micron level stability is non-negotiable.

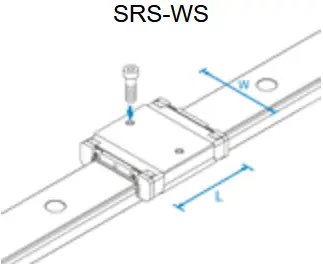

The THK LM Guide Caged Ball LM Guide Miniature Model SRS, SRS-WS Series represents a significant evolution in compact linear motion technology, specifically engineered for applications where space is at a premium but performance cannot be compromised. This series utilizes a unique caged ball design, where precision balls are individually retained and separated by a specially engineered polymer cage. This fundamental design principle eliminates ball-to-ball contact, drastically reducing friction, heat generation, and torque variation compared to conventional, non-caged ball guides. The result is exceptionally smooth, quiet, and consistent motion, even at high speeds.

Key technical features define the superior performance of the SRS and SRS-WS Series. The compact, low-profile design is a primary characteristic, allowing for integration into tightly constrained mechanisms. The caged ball structure not only ensures smooth operation but also prevents the balls from falling out during handling or assembly, simplifying installation and maintenance. The SRS-WS variant further enhances versatility with a wide, low-profile rail, offering increased moment load capacity and rigidity for applications requiring enhanced stability. These guides are manufactured from high-carbon chromium bearing steel, hardened to optimal levels and finished with precision grinding to achieve exceptional raceway accuracy. Optional seals and scrapers are available to provide robust protection against contaminants like dust, chips, and moisture, ensuring long-term reliability and a maintenance-free service life in harsh environments.

The performance advantages are substantial, directly translating into tangible benefits for machinery designers. The significant reduction in friction leads to lower driving force requirements, allowing for the use of smaller, more energy-efficient motors and drives. The consistent, low-friction motion enables higher positioning accuracy and repeatability, which is critical for precision tasks. The inherent quietness of the caged ball system contributes to a better working environment and is ideal for noise-sensitive applications. Furthermore, the elimination of ball-to-ball contact minimizes wear and extends the operational lifespan of the guide, reducing total cost of ownership.

Typical applications for the miniature SRS and SRS-WS Series are found across industries demanding precision and reliability in a small form factor. In industrial machinery, they are extensively used in the linear axes of semiconductor and electronics manufacturing equipment, PCB drilling and routing machines, precision assembly robots, and miniature coordinate measuring machines (CMMs). Within the automotive sector, these guides are ideal for sensitive components in fuel injection testing apparatus, precision sensor positioning systems, and automated inspection devices on production lines. In the broader field of precision equipment, they are the component of choice for medical and diagnostic devices, optical positioning stages, laboratory automation systems, and high-speed pick-and-place units, where their compact size, smooth motion, and high accuracy are indispensable for optimal system performance.

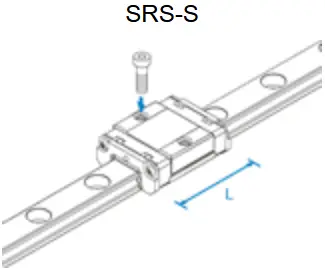

THK's LM Guide Caged Ball LM Guide Miniature Model SRS/SRS S SERIES represents a specialized advancement in compact linear motion technology, engineered for applications where space constraints and precision are paramount. This series incorporates a unique caged ball design where precision steel balls are retained and guided by a resin cage, eliminating ball-to-ball contact and reducing friction significantly. The compact cross-section and lightweight construction make it ideal for miniaturized equipment without sacrificing load capacity or rigidity.

Key technical features include the caged ball mechanism that minimizes torque variation and ensures smooth, consistent motion even at high speeds. The SRS/SRS S SERIES is available in various sizes with standardized dimensions, facilitating easy integration into existing systems. It offers four accuracy classes (Normal, High, Precision, and Ultra-Precision) to match diverse application requirements. The guides are constructed from high-carbon chromium bearing steel, heat-treated for enhanced durability and wear resistance. Sealing options, such as stainless steel seals or rubber scrapers, provide effective protection against contaminants like dust and chips, extending service life in harsh environments.

Performance advantages are notable in several areas. The caged ball design reduces heat generation and lubrication demands, allowing for maintenance-free operation in many cases. This results in higher operational speeds and accelerations while maintaining low noise levels, critical in sensitive settings. The series delivers high positional accuracy and repeatability, with error margins as tight as a few micrometers in ultra-precision models. Its compact design supports space-saving layouts, enabling more efficient machine designs. Additionally, the low-friction operation contributes to energy efficiency, reducing overall power consumption in automated systems.

Typical applications span industries where precision and miniaturization are essential. In industrial machinery, the SRS/SRS S SERIES is used in semiconductor manufacturing equipment, such as wafer handling robots and inspection systems, where rapid, precise movements are crucial. In automotive systems, it finds roles in assembly robots, fuel injection testing devices, and small-scale automation components that require reliability in confined spaces. For precision equipment, it is integral to medical devices like DNA analyzers and surgical instruments, optical alignment systems in telescopes or microscopes, and compact measuring instruments. The series' robustness also suits packaging machinery, textile equipment, and electronic component placement systems, where consistent performance under repetitive motion is vital. Overall, THK's miniature caged ball LM guides provide a reliable solution for high-speed, high-accuracy linear motion in demanding, space-limited applications.

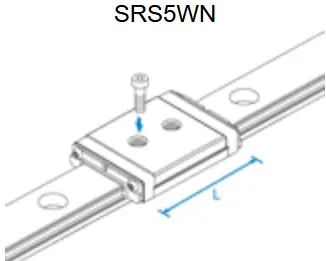

The THK LM Guide Caged Ball LM Guide Miniature Model SRS SRS5WN SERIES represents a specialized advancement in compact linear motion technology, engineered for applications demanding minimal space utilization without sacrificing performance or reliability. This series incorporates a unique caged ball design where precision balls are securely retained within a polymer cage. This configuration fundamentally eliminates ball-to-ball contact, drastically reducing friction, heat generation, and torque variation. The result is a smoother, more consistent motion with exceptionally low and stable running resistance, even at high speeds.

Key technical features of the SRS5WN series begin with its miniature dimensions, offering a compact cross-section ideal for tight installation spaces. The incorporation of the caged ball mechanism is its cornerstone, which not only enhances smoothness but also prevents ball recirculation issues and minimizes noise during operation. The guide rails and blocks are manufactured from high-carbon chromium bearing steel, subjected to rigorous heat treatment to achieve a surface hardness of approximately HRC 58 or higher, ensuring exceptional wear resistance and long-term precision. Sealing is addressed with integrated seals or scrapers that effectively shield the ball recirculation paths from contaminants like dust and chips, thereby maintaining lubricant integrity and extending service life. The series is designed for easy installation and offers high rigidity, capable of handling moments and loads in multiple directions.

The performance advantages derived from these features are significant. The low-friction caged ball design translates directly into higher maximum speeds and superior acceleration capabilities, making it suitable for rapid reciprocating motions. The stability of the friction coefficient ensures predictable and precise positioning, which is critical for automated processes. The enhanced sealing provides remarkable reliability in challenging environments, reducing maintenance frequency and downtime. Furthermore, the quiet operation is a distinct benefit in noise-sensitive settings like laboratory or medical equipment.

Typical applications for the SRS5WN SERIES are found wherever space is at a premium and performance is non-negotiable. In industrial automation, these guides are integral to the linear axes of compact pick-and-place robots, precision assembly machines, and the sliding doors of enclosures. Within the automotive sector, they are employed in advanced manufacturing systems for small-part handling, sensor positioning units, and testing equipment. In the realm of precision equipment, the SRS5WN is a preferred component for optical instrument stages, semiconductor and LCD manufacturing machinery, and various medical devices requiring smooth, quiet, and dependable linear motion. Its combination of miniaturization, high-speed capability, and robust construction makes it a versatile solution for advancing the efficiency and capabilities of modern machinery.

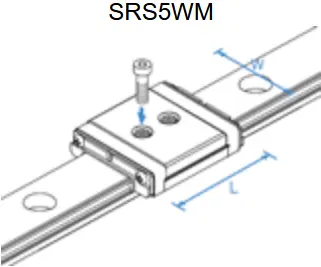

The THK LM Guide Caged Ball LM Guide Miniature Model SRS SRS5WM SERIES represents a significant advancement in compact linear motion technology, engineered for applications where space constraints and precision are paramount. This series incorporates a unique caged ball design, where precision balls are securely held within a resin retainer, effectively eliminating metal-to-metal contact between the balls. This configuration drastically reduces friction and heat generation, allowing for significantly higher operating speeds—up to 2.5 times faster than conventional linear guides—and providing exceptional smoothness and quiet operation. The compact SRS5WM model is characterized by its small cross-sectional dimensions and a low center of gravity, making it ideal for integration into tightly spaced machinery assemblies.

Key technical features define the performance envelope of this series. The caged ball mechanism is central, preventing ball-to-ball contact and the resulting friction and torque fluctuations, which ensures consistent, smooth motion and extends the operational life of the guide. The balls are arranged in a precise 4-row circular arc groove configuration, providing a high load capacity in all directions—radial, reverse-radial, and lateral. The incorporation of a highly efficient seal system, often including metal and rubber seals, effectively protects the critical ball rolling surfaces from contaminants like dust and chips, ensuring reliability in demanding environments. The guide rails and blocks are manufactured from high-carbon chromium bearing steel, heat-treated to a surface hardness of approximately HRC 58, guaranteeing exceptional wear resistance and long-term precision retention.

The performance advantages of the SRS SRS5WM SERIES translate directly into tangible benefits for equipment designers and operators. The low friction inherent in the caged ball design results in a remarkably low starting friction coefficient, ensuring precise and responsive movement without stick-slip, which is critical for high-accuracy positioning. The ability to operate at high speeds without excessive heat build-up increases machine throughput and cycle times. Furthermore, the elimination of ball-to-ball contact and the effective sealing dramatically extend the lubrication intervals and service life, reducing maintenance requirements and total cost of ownership. The compact and lightweight nature of the miniature model allows for the design of smaller, more agile machines without sacrificing performance or rigidity.

Typical applications for this high-precision miniature guide are found across industries where miniaturization, speed, and accuracy are non-negotiable. In industrial automation, it is extensively used in the linear axes of high-speed pick-and-place robots, precision assembly machines, and the sliding bases of semiconductor and electronic component manufacturing equipment. Within the automotive sector, it finds roles in precision testing and measurement instruments, small-scale robotic welders on assembly lines, and automated optical inspection systems for parts. In the broader field of precision equipment, the SRS5WM is an ideal component for medical and diagnostic devices, precision stages in coordinate measuring machines (CMMs), and the moving parts of advanced office automation equipment, providing the reliable, smooth, and accurate motion required for next-generation technology.

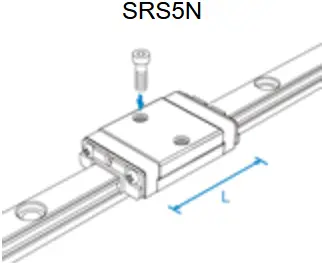

The THK LM Guide Caged Ball LM Guide Miniature Model SRS SRS5N SERIES represents a specialized advancement in compact linear motion technology, engineered for applications where space constraints and precision are paramount. This series incorporates a unique caged ball design, where precision balls are individually housed and separated by a resin retainer. This configuration fundamentally reduces friction, minimizes heat generation, and virtually eliminates metal-to-metal contact between the balls, leading to a dramatic increase in operational smoothness and service life.

Key technical features define the performance edge of the SRS5N series. Its miniature footprint is a primary characteristic, offering a low profile and compact cross-section ideal for integration into densely packed machinery. The caged ball mechanism is central to its advantages; by preventing ball-to-ball contact, it eliminates the risk of abrasive wear and extends lubrication intervals significantly. This design also allows for higher maximum speeds and accelerations compared to conventional retainer-less designs, as it mitigates ball skidding and reduces torque variation. The guides are manufactured from high-grade steel, precision-hardened and ground to provide exceptional rigidity and resistance to deformation under load. Furthermore, the series is available with various preload options and accuracy grades, enabling fine-tuning for specific application requirements, from general automation to high-precision positioning.

The performance advantages translate directly into enhanced machine capability and reliability. The reduced friction inherent in the caged ball system results in lower driving force requirements, which can allow for the use of smaller, more energy-efficient motors and drives. The exceptional smoothness of motion ensures highly accurate and repeatable positioning, critical for processes involving delicate components or precise measurements. The extended lubrication life and superior wear resistance contribute to dramatically reduced maintenance downtime and total cost of ownership, making it a highly reliable component in continuous operation environments.

Typical applications for the SRS5N series are found across industries demanding precision in a small form factor. In industrial automation, these guides are integral to the linear axes of compact pick-and-place robots, precision assembly machines, and the sliding bases of semiconductor and electronic component manufacturing equipment. Within the automotive sector, they are employed in precision testing and measurement devices, small-scale robotic welders on assembly lines, and advanced sensor positioning systems. In the realm of precision equipment, the SRS5N is a critical component in medical devices such as DNA sequencers and automated analysis instruments, optical positioning stages, and high-accuracy coordinate measuring machines (CMMs), where its miniature size, smooth motion, and unwavering accuracy are indispensable for system performance.

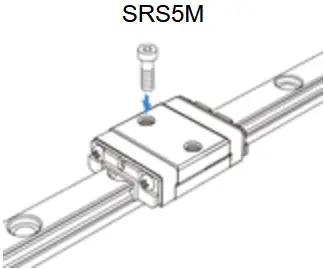

The THK LM Guide Caged Ball LM Guide Miniature Model SRS SRS5M SERIES represents a specialized evolution in compact linear motion technology, engineered for applications where space constraints, precision, and reliability are paramount. This series incorporates a unique caged ball design, where precision steel balls are individually retained within a polymer cage. This fundamental construction eliminates ball-to-ball contact, drastically reducing friction, heat generation, and torque variation. The result is an exceptionally smooth, quiet, and consistent motion, even at high speeds. The compact SRS5M profile is specifically designed for miniature equipment, offering a low height and a slim cross-section that maximizes design flexibility in tightly confined spaces.

Key technical features define the performance superiority of this series. The caged ball mechanism is its cornerstone, preventing the sliding friction common in standard retainer designs and ensuring a longer, maintenance-free service life by minimizing wear and the need for re-lubrication. The SRS structure, with its four-directional equal load capacity, allows the guide to handle radial, reverse-radial, and lateral loads simultaneously. This makes the system remarkably rigid and stable, capable of sustaining high moment loads without compromising accuracy. The raceway grooves are precision-ground to micro-accuracy standards, ensuring high positional repeatability and smooth rolling motion. Furthermore, the inclusion of high-performance seals effectively guards the critical recirculating components against dust, chips, and other contaminants, making the unit highly durable in demanding environments.

The performance advantages of the SRS SRS5M SERIES translate directly into operational benefits. The low friction inherent in the caged ball design leads to significantly lower driving force requirements, allowing for the use of smaller, more energy-efficient motors and drives. The exceptional smoothness of operation minimizes vibration and noise, which is critical in sensitive laboratory or medical settings. Its high rigidity and accuracy ensure that machinery can perform precise, repetitive tasks without deviation, enhancing overall product quality and manufacturing throughput. The extended lubrication intervals and robust sealing reduce total cost of ownership by minimizing downtime for maintenance and preventing premature failure from contamination.

Typical applications for this miniature LM Guide are found across industries that demand precision in a small footprint. In industrial automation, it is integral to the function of compact pick-and-place robots, precision assembly arms, and miniature linear actuators. Within the automotive sector, it is employed in advanced manufacturing systems for electronic component assembly, sensor testing equipment, and delicate fuel injection machining apparatus. In the realm of precision equipment, the SRS5M SERIES is indispensable. It is the motion solution of choice for the stages of semiconductor manufacturing equipment, optical inspection devices, medical diagnostic analyzers, and high-precision coordinate measuring machines (CMMs), where its flawless motion characteristics guarantee the utmost accuracy and reliability.