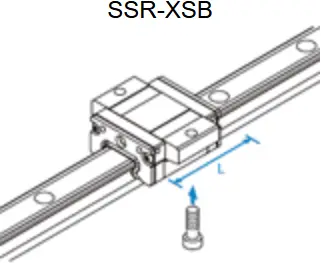

THK's LM Guide Caged Ball LM Guide Radial Type Model SSR, SSR XSB, and SERIES represent a significant advancement in linear motion technology, engineered to deliver exceptional precision, rigidity, and longevity in demanding applications. These guides incorporate a unique caged ball design where precision steel balls are retained and separated by a polymer cage, effectively eliminating metal-to-metal contact between the balls. This design drastically reduces friction, heat generation, and torque variation, while also preventing the balls from falling out during handling or maintenance, ensuring easier and safer installation. The radial-type structure provides a compact, high-rigidity configuration ideal for withstanding substantial loads from all directions, including radial, reverse-radial, and lateral moments.

Key technical features of this series include the use of high-grade steel for the tracks and balls, ensuring high load capacity and wear resistance. The optimized ball groove geometry and precise preload adjustment mechanisms contribute to smooth, near-silent motion with exceptional positional accuracy and repeatability. The caged ball system is particularly advantageous for high-speed operation, as it minimizes ball-to-ball friction and the risk of skidding, leading to more stable motion and reduced vibration. For corrosion resistance in harsh environments, many models offer stainless steel options or specialized seals and wipers that effectively exclude contaminants like dust, chips, and moisture, thereby extending the service life even in challenging conditions like machine tools or cleanrooms.

The performance advantages of the SSR, SSR XSB, and SERIES translate directly into operational benefits for end-users. The low friction characteristics result in lower driving force requirements, allowing for the use of smaller, more energy-efficient motors and drives. The high rigidity ensures minimal deflection under load, which is critical for maintaining machining accuracy in CNC equipment or precision in measuring instruments. The extended maintenance intervals and long service life, a direct result of the caged ball design reducing wear and lubricant degradation, significantly lower the total cost of ownership over the system's lifecycle.

These linear guides are typically deployed in a wide array of high-performance applications. In industrial machinery, they are fundamental components in CNC machining centers, grinding machines, and electric discharge machines (EDMs), where their precision and rigidity are paramount for achieving tight tolerances and fine surface finishes. Within automotive manufacturing systems, they are found in robotic welding arms, automated assembly lines, and precision testing equipment, providing the reliable, high-speed motion required for mass production. In the realm of precision equipment, these guides are integral to semiconductor manufacturing apparatus, optical positioning stages, and medical imaging devices like CT and MRI scanners, where smooth, vibration-free, and highly accurate linear motion is non-negotiable for product quality and diagnostic integrity.

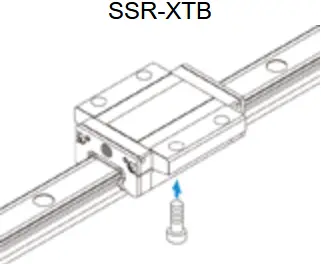

The THK LM Guide Caged Ball LM Guide Radial Type Model SSR, SSR XTB SERIES represents a significant advancement in linear motion technology, engineered to deliver exceptional precision, rigidity, and longevity in demanding industrial applications. This series incorporates a unique caged ball design where precision steel balls are securely held within a polymer retainer, effectively eliminating metal-to-metal contact between the balls. This configuration drastically reduces friction, heat generation, and torque variation, while simultaneously preventing ball-to-ball friction that can lead to wear and noise. The radial-type structure is optimized to support loads acting perpendicular to the mounting surface, providing robust performance for a wide array of automation and machinery needs.

Key technical features define the superiority of this series. The caged ball mechanism is its cornerstone, ensuring smooth, consistent motion and a substantial increase in operational life by minimizing wear on the ball tracks. The SSR XTB variants are further equipped with an integral seal design that offers superior protection against contaminants like dust, chips, and moisture, making them ideal for harsh environments. These guides are manufactured with high-grade steel and undergo rigorous heat treatment processes to achieve exceptional hardness and durability. The compact, low-profile design of the SSR series allows for space-saving integration into machinery without compromising on load capacity or moment resistance. Pre-loaded options are available to eliminate internal clearance, granting high positional accuracy and remarkable rigidity for precision tasks.

The performance advantages are immediately apparent in operational settings. The reduction in friction translates directly to lower driving force requirements, enabling the use of smaller, more energy-efficient motors and contributing to overall system cost savings. The enhanced rigidity and damping characteristics minimize deflection and vibration under load, which is critical for maintaining accuracy during high-speed movements and heavy cutting operations. The extended service life, a direct result of the caged ball design and effective sealing, significantly reduces maintenance frequency and total cost of ownership, maximizing machine uptime and productivity.

Typical applications for the THK SSR and SSR XTB SERIES are found across high-precision industries. In industrial machinery, they are indispensable in CNC machining centers for axis drives, high-speed feed units, and precision grinding machines. The automotive manufacturing sector utilizes them in robotic welding arms, automated assembly lines, and precision testing equipment where reliability and repeatability are paramount. Within the realm of precision equipment, these guides are integral to the function of semiconductor manufacturing apparatus, optical positioning stages, and various medical devices, including automated analysis and imaging systems. Their robust construction and contamination resistance also make them suitable for packaging machinery, printing presses, and other applications where continuous, reliable linear motion is a fundamental requirement for success.

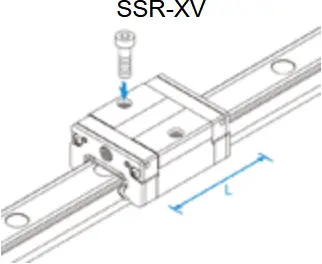

THK's SSR, SSR-XV Series represents a significant advancement in linear motion technology with its Caged Ball LM Guide Radial Type design. This innovative configuration features precision balls retained within a robust cage structure, fundamentally eliminating ball-to-ball contact during operation. The radial-type construction ensures optimal load distribution across all rolling elements, delivering exceptional rigidity and smooth motion characteristics essential for high-precision applications. These guides incorporate THK's proprietary engineering with precisely ground raceways and optimized ball circulation paths that maintain consistent performance throughout the operational lifespan.

The technical architecture of the SSR Series demonstrates remarkable engineering sophistication. The caged ball design prevents torque fluctuations and reduces friction by up to 90% compared to conventional slide systems, while simultaneously eliminating the need for regular relubrication maintenance. The SSR-XV variant further enhances performance with specialized seals and wipers that provide superior contamination protection in harsh environments. Both series maintain exceptional accuracy with running parallelism precision within micrometers and can withstand moment loads exceeding standard linear guides by significant margins. The compact cross-section design maximizes space utilization while supporting load capacities ranging from basic automation requirements to heavy-duty industrial applications.

Performance advantages manifest across multiple operational parameters. The elimination of ball-to-ball contact translates to dramatically reduced noise levels – typically measuring below 65 dB even at high speeds – making these guides ideal for cleanroom and laboratory environments. Maintenance intervals extend significantly, with lubrication requirements reduced by approximately 80% compared to conventional designs. The optimized ball recirculation system ensures consistent preload retention, maintaining positioning accuracy within ±2μm over millions of travel cycles. Thermal deformation remains minimal due to the symmetrical load distribution, ensuring stable performance across temperature variations from -10°C to 80°C.

Industrial implementation spans diverse sectors where precision and reliability are paramount. In semiconductor manufacturing equipment, SSR guides facilitate sub-micron positioning accuracy in wafer handling robots and photolithography stages. Automotive production lines utilize these components in robotic welding arms and precision assembly fixtures where vibration resistance and long-term accuracy are critical. Medical device manufacturers incorporate SSR Series guides in diagnostic scanner positioning systems and surgical robot articulation joints. The series also finds extensive application in precision measuring instruments, optical alignment equipment, and high-speed packaging machinery where smooth motion characteristics directly impact product quality and throughput.

The structural integrity of these guides enables direct integration into machine frameworks without additional support structures, simplifying design while reducing overall system weight. Corrosion-resistant variants with special surface treatments are available for applications involving chemical exposure or high humidity environments. Customizable lengths and pre-travel lubrication options allow for tailored solutions matching specific application requirements, while the standardized mounting dimensions ensure compatibility with existing automation infrastructure.

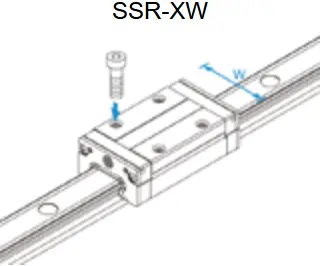

The THK LM Guide Caged Ball LM Guide Radial Type Model SSR, SSR XW SERIES represents a significant evolution in linear motion technology, engineered for applications demanding high rigidity, exceptional precision, and long-term operational reliability. This series utilizes a unique caged ball design, where precision balls are individually retained and separated by a robust polymer cage. This fundamental design principle eliminates metal-to-metal contact between the balls, drastically reducing friction, heat generation, and wear. The radial-type configuration ensures that the load-bearing balls are optimally positioned to support radial loads, making these guides exceptionally robust for a wide range of industrial challenges.

Key technical features define the performance envelope of the SSR and SSR XW series. The caged ball mechanism is paramount, as it prevents ball-to-ball friction, minimizes torque fluctuation, and ensures smooth, consistent motion at both high and low speeds. This design also allows for significantly higher maximum speeds compared to standard retainer-type linear guides. The guides are constructed with high-grade steel, featuring precision-ground raceways that provide a high degree of accuracy and repeatability. For enhanced corrosion resistance in harsh environments, many models are available with THK's proprietary "XW" coating. The compact cross-section of the SSR series facilitates space-saving machine design without compromising load capacity or moment rigidity. Furthermore, the inclusion of optional seals and wipers effectively protects the critical ball-raceway interface from contaminants like dust, chips, and moisture, thereby extending service life and reducing maintenance requirements.

The performance advantages derived from these features are substantial. The reduction in friction directly translates to lower driving force requirements, enabling the use of smaller, more energy-efficient motors and drives. The exceptional smoothness of motion is critical for applications involving precise positioning and high-quality surface finishes. The high rigidity and load capacity ensure minimal deformation under load, maintaining accuracy even during heavy-duty operations. The extended service life, a direct result of reduced wear and effective sealing, dramatically lowers the total cost of ownership by minimizing unplanned downtime and replacement part costs.

Typical applications for the THK SSR and SSR XW SERIES are found across demanding sectors of industrial automation. In industrial machinery, they are indispensable in high-speed machining centers, CNC lathes, grinding machines, and industrial robots where precision, speed, and durability are non-negotiable. The automotive industry leverages these guides in automated assembly lines, precision welding equipment, and high-speed material handling systems. Within the realm of precision equipment, the SSR series excels in semiconductor manufacturing apparatus, optical positioning stages, precision measuring instruments, and medical device automation, where micron-level accuracy and flawless motion smoothness are paramount. Its robust construction and reliability make it the linear motion solution of choice for engineers designing the next generation of high-performance automated systems.