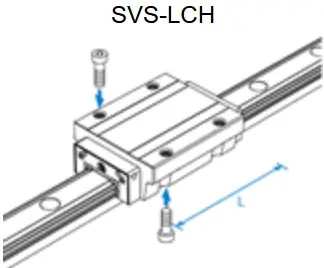

The THK LM Guide Caged Ball LM Guide Ultra Heavy Load (4-Way) Model SVS/SVS LCH SERIES represents a pinnacle of engineering for applications demanding extreme load capacity, rigidity, and precision under the most punishing operational conditions. This series is specifically engineered with a unique caged ball design, where precision balls are securely retained and guided by a robust polymer cage. This fundamental innovation prevents ball-to-ball contact, drastically reducing friction, heat generation, and torque variation, while simultaneously allowing for significantly higher speeds and a cleaner, more maintenance-friendly operation by preventing lubricant starvation.

Technically, the "Ultra Heavy Load" designation is achieved through its 4-way equal load capacity. The patented Gothic arch groove design in the raceway enables the system to bear substantial loads from all four primary directions—radial, reverse radial, and lateral—with exceptionally high rigidity and moment capacity. This ensures unparalleled stability and accuracy, even when subjected to complex combined loads and overturning moments that would compromise conventional guides. The SVS LCH variant further enhances this capability with a specialized seal configuration and a lubricator unit, ensuring long-term reliability and consistent performance in environments contaminated with dust, chips, or other particulates.

The performance advantages of the SVS/SVS LCH SERIES are transformative for heavy-duty automation. The caged ball system yields a dramatic increase in permissible speed by mitigating the centrifugal forces that eject balls in standard retainer-less designs. This results in smoother, quieter, and more vibration-free motion, which is critical for preserving positional accuracy and surface finish in machining operations. Furthermore, the consistent friction and effective lubrication management lead to a substantially longer service life and reduced total cost of ownership by extending relubrication intervals and minimizing unexpected downtime.

Typical applications for this robust linear motion solution are found wherever massive loads and high precision must coexist. In industrial machinery, it is indispensable for the vertical axes of heavy-duty machining centers, large-scale transfer lines, and the gantry systems of high-precision boring mills. Within the automotive manufacturing sector, these guides are deployed in massive stamping press feeders, robotic welding cells handling large car body assemblies, and precision testing equipment for powertrain components. In the realm of precision equipment, the SVS/SVS LCH SERIES provides the foundational stability for large-format semiconductor and LCD panel manufacturing systems, precision optical grinding machines, and advanced coordinate measuring machines (CMMs) where thermal stability and minimal deflection are non-negotiable.

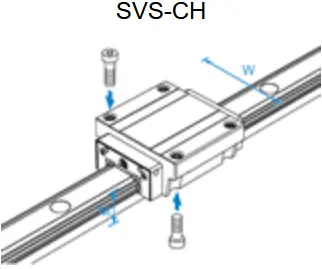

THK's LM Guide Caged Ball LM Guide Ultra Heavy Load (4-Way) Model SVS/SVS CH SERIES represents a significant advancement in linear motion technology, engineered specifically for applications demanding exceptional load capacity, rigidity, and precision under the most challenging industrial conditions. This series incorporates a unique caged ball design where precision balls are retained and guided by a robust cage, effectively minimizing friction, reducing heat generation, and eliminating metal-to-metal contact between the balls. The "4-way equal load" configuration is a cornerstone of its design, enabling the guide to handle substantial loads—including moment loads—from all four primary directions (radial, reverse radial, and lateral) with remarkable stability. This makes the SVS/SVS CH SERIES ideally suited for ultra-heavy-duty operations where standard linear guides would be prone to premature failure or excessive deflection.

Key technical features of this series include a generously sized ball diameter and a optimized circular-arc groove contact structure, which collectively maximize contact area between the balls and the raceway. This design significantly enhances load capacity and rigidity, ensuring minimal deformation even under extreme forces. The incorporation of the caged ball mechanism not only prevents ball-to-ball friction, reducing operational noise and wear, but also allows for smoother motion at high speeds and more consistent performance over an extended service life. For lubrication and maintenance, the series is designed with efficient grease retention capabilities and optional lubrication units, ensuring optimal performance in environments where frequent maintenance is impractical. Sealing is addressed with high-performance seals or scrapers that effectively exclude contaminants like dust, chips, and moisture, making these guides reliable in harsh manufacturing settings such as metalworking, heavy assembly, or outdoor applications.

The performance advantages of the SVS/SVS CH SERIES translate directly into operational benefits for end-users. Its ultra-high load capacity and rigidity ensure unparalleled accuracy and repeatability in positioning, which is critical for applications involving heavy workpieces or high-moment loads. The reduced friction from the caged ball design leads to lower driving force requirements, enabling the use of smaller, more energy-efficient motors and drives while maintaining smooth, stick-slip-free motion. This efficiency, combined with the guide's durability, results in lower total cost of ownership through reduced energy consumption, minimal maintenance downtime, and extended component life. Furthermore, the series' ability to maintain precision under heavy loads ensures consistent product quality and reduces the risk of machining or assembly errors.

Typical applications for the THK SVS/SVS CH SERIES are found across industries where reliability under extreme loads is non-negotiable. In industrial machinery, it is extensively used in heavy-duty machining centers, large-scale transfer lines, injection molding machines, and press-feeding equipment, where it provides the stability needed for precise tool positioning and heavy workpiece handling. Within automotive manufacturing systems, these guides are employed in robotic welding arms, large assembly jigs, and stamping press automation, enduring high dynamic loads and ensuring repeatable alignment in high-volume production environments. For precision equipment, the series finds use in large-scale semiconductor manufacturing apparatus, precision grinding machines, and optical lens polishing equipment, where its rigidity and accuracy are essential for maintaining micron-level tolerances. Its robust construction also makes it suitable for heavy material handling systems, such as gantry robots and automated storage and retrieval systems (AS/RS), where it supports and guides massive loads with unwavering reliability.

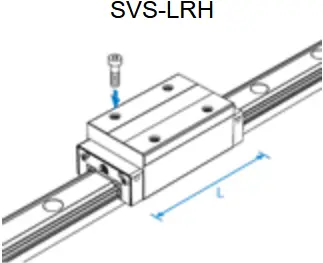

The THK LM Guide Caged Ball LM Guide Ultra Heavy Load (4-Way) Model SVS/SVS LRH SERIES represents a significant advancement in linear motion technology, engineered specifically for applications demanding exceptional load capacity, rigidity, and precision under the most severe operating conditions. This series incorporates a unique caged ball design where precision steel balls are securely retained within a polymer cage, effectively eliminating metal-to-metal contact between the balls. This fundamental design innovation drastically reduces friction, minimizes heat generation, and virtually eliminates the risk of ball-to-ball contact, which can cause noise, vibration, and accelerated wear. The "4-Way" equal load characteristic is a cornerstone of its performance, enabling the guide to handle substantial loads—including moment loads—from all four primary directions (radial, reverse radial, and lateral) with remarkable stability.

Key technical features of the SVS/SVS LRH SERIES include its optimized raceway geometry, which ensures a large contact area between the balls and the raceways, distributing loads evenly to achieve an ultra-high load rating and exceptional rigidity. The incorporation of the caged ball structure not only enhances operational smoothness but also significantly improves grease retention, leading to longer lubrication intervals and reduced maintenance requirements. For applications requiring even greater precision and minimal friction, the SVS LRH variant features a Land Roller Retainer (LRH) system, further refining the motion characteristics. These guides are manufactured to the highest tolerances from premium materials, often featuring corrosion-resistant treatments or stainless-steel options for harsh environments, ensuring long-term dimensional stability and reliability.

The performance advantages are substantial, translating directly into enhanced machine productivity and longevity. The ultra-high load capacity allows for the design of more compact machinery, as a single SVS guide can often replace larger or multiple conventional guides. The exceptional rigidity ensures minimal deflection under heavy cutting forces or process loads, directly contributing to improved machining accuracy and surface finish in manufacturing equipment. The low-friction, caged ball design results in highly consistent motion with excellent starting and running torque, enabling precise positioning and high-speed operation without sacrificing smoothness or generating excessive noise. This combination of high load, high rigidity, and low friction also contributes to superior damping characteristics, absorbing vibrations that could otherwise compromise precision.

Typical applications for the THK SVS/SVS LRH SERIES are found in demanding sectors where reliability and precision are non-negotiable. In industrial machinery, they are indispensable in heavy-duty machining centers, high-precision grinding machines, injection molding machines, and large-scale material handling and transfer systems. The automotive industry utilizes these guides in robotic welding and assembly lines, heavy-duty press feeds, and precision testing equipment. Within the realm of precision equipment, they are critical components in semiconductor manufacturing apparatus, flat panel display production systems, and large-scale coordinate measuring machines (CMMs), where their ability to maintain accuracy under significant loads is paramount. The SVS/SVS LRH SERIES thus provides a robust, high-performance foundation for the most challenging linear motion applications across modern industry.

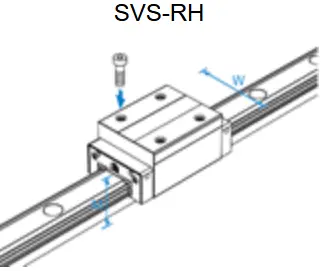

THK's LM Guide Caged Ball LM Guide Ultra Heavy Load (4-Way) Model SVS/SVS RH SERIES represents a pinnacle in linear motion technology, engineered specifically for applications demanding exceptional load capacity, rigidity, and precision under the most strenuous conditions. This series incorporates a unique caged ball design where precision-engineered balls are retained and guided by a robust cage, effectively eliminating metal-to-metal contact between the balls. This fundamental design principle drastically reduces friction, minimizes heat generation, and virtually eliminates the wear and torque variation typically associated with conventional linear motion systems. The "4-Way" load designation signifies its superior capability to handle heavy loads from all directions—radial, reverse radial, and lateral—making it an exceptionally stable and versatile solution.

The technical features of the SVS/SVS RH SERIES are meticulously crafted for ultra-heavy-duty performance. The incorporation of the ball cage is critical, as it prevents ball-to-ball friction, ensuring smooth, consistent motion and significantly extending the operational life of the guide by maintaining lubrication within the raceways. The series is constructed from high-grade steel, subjected to THK's proprietary heat treatment processes to achieve an optimal balance of surface hardness for wear resistance and a tough, shock-absorbent core. This results in a product with high static load ratings and moment load capacities that far exceed those of standard linear guides. The SVS RH models include pre-drilled mounting holes and standardized dimensions, simplifying installation and integration into complex machinery, thereby reducing assembly time and potential for error.

Performance advantages are substantial and directly address the challenges of high-demand automation. The primary benefit is unparalleled rigidity and stability under ultra-heavy loads, which translates into exceptional positional accuracy and repeatability. This rigidity suppresses deflection and vibration, critical for maintaining precision in machining and measurement applications. The low-friction, caged ball design ensures smooth movement with minimal starting friction, enabling highly precise control at low speeds and contributing to energy efficiency by reducing the force required for actuation. Furthermore, the design promotes long-term maintenance-free operation, as the cage retains lubricant and protects the rolling elements from contamination, a key factor in harsh industrial environments.

Typical applications for this robust series are found wherever massive loads and precision must coexist. In industrial machinery, it is indispensable for heavy-duty machining centers, large-scale transfer lines, injection molding machines, and precision grinding equipment, where it provides the foundational stability for high-precision material removal. Within automotive manufacturing systems, the SVS/SVS RH SERIES is deployed in robotic welding arms handling heavy car bodies, large press automation, and precision assembly stations for engines and transmissions. In the realm of precision equipment, it facilitates the movement of heavy lenses and components in semiconductor and LCD manufacturing systems, large coordinate measuring machines (CMMs), and advanced optical positioning stages, where its rigidity ensures nanometer-level accuracy is maintained despite significant mass.

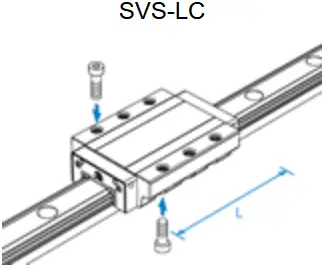

The THK LM Guide Caged Ball LM Guide Ultra Heavy Load (4-Way) Model SVS/SVS LC SERIES represents a significant advancement in linear motion technology, engineered specifically for applications demanding exceptional load capacity, rigidity, and precision under the most challenging operational conditions. This series incorporates a unique caged ball design where precision balls are securely held and guided by a robust polymer retainer. This fundamental design eliminates metal-to-metal contact between the balls, drastically reducing friction, heat generation, and torque variation. The "4-Way" equal load capacity is a defining characteristic, meaning the guide can handle equivalent loads from all four primary directions—radial, reverse radial, and lateral—providing unparalleled stability and performance symmetry.

Key technical features of the SVS/SVS LC SERIES include its ultra-heavy load rating, which is achieved through an optimized ball groove geometry and the use of large-diameter, high-carbon chromium steel balls. The caged ball structure is critical, as it prevents ball-to-ball friction and ensures smooth, consistent motion even at high speeds or under moment loads. The SVS LC variant often includes additional corrosion-resistant treatments or materials, making it suitable for harsh environments. The design also incorporates a sealed configuration with integrated scrapers and end seals to effectively exclude contaminants like dust, chips, and moisture, while retaining lubrication for extended service life and minimal maintenance.

The performance advantages are substantial. The reduction in friction directly translates to higher efficiency, lower energy consumption, and significantly longer operational life compared to standard linear guides. The exceptional rigidity and 4-way load capacity ensure minimal deformation under heavy loads, guaranteeing high positional accuracy and repeatability. This stability is crucial for preventing deflection and maintaining precision during machining or assembly processes. The smooth motion profile also contributes to reduced vibration and noise, leading to a quieter operation and higher quality finished products.

Typical applications for this robust series are found in sectors where reliability and precision under extreme loads are non-negotiable. In industrial machinery, it is indispensable for heavy-duty machining centers, large-scale transfer lines, injection molding machines, and precision grinding equipment. Within automotive manufacturing systems, the SVS/SVS LC SERIES is deployed in robotic welding arms, heavy-part positioning fixtures, and automated stamping press feeds. In the realm of precision equipment, it provides the foundational stability for semiconductor manufacturing apparatus, large-format coordinate measuring machines (CMMs), and advanced optical alignment systems, where any deviation under load would be catastrophic to the process. This series is engineered not just for motion, but for unwavering performance where failure is not an option.

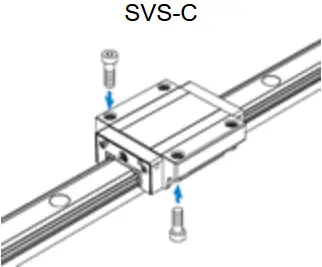

The THK LM Guide Caged Ball LM Guide Ultra Heavy Load (4-Way) Model SVS SVS C SERIES represents a pinnacle of engineering for applications demanding exceptional load capacity, rigidity, and precision under the most severe operating conditions. This series is specifically designed as a 4-way equal load ball recirculating linear guide, which means it can handle loads of the same magnitude from all four primary directions—radial, reverse radial, and lateral—with outstanding stability. The defining innovation of this model is its incorporation of a caged ball design. A polymer resin retainer precisely spaces and houses the load-carrying steel balls, effectively eliminating metal-to-metal contact between them. This fundamental design principle mitigates friction, reduces heat generation, and dramatically lowers the required driving force, while simultaneously extending the system's operational life by minimizing wear and lubricant degradation.

Key technical features that enable its robust performance include a significantly increased ball count and optimized contact angles. By maximizing the number of load-bearing elements, the SVS C SERIES distributes forces more evenly across the rail and block, directly contributing to its ultra-high load ratings. The construction ensures exceptional rigidity and resistance to moment loads, maintaining accuracy even when subjected to heavy overturning forces, shock, and vibration. The caged ball system also provides superior high-speed performance, as the controlled ball circulation prevents chaotic motion and noise, which is a common limitation in conventional designs. Furthermore, the seals are engineered for high debris resistance, making this guide highly suitable for harsh environments where contamination from chips, dust, or other particulates is a concern.

The performance advantages of the SVS C SERIES translate directly into enhanced machine capability and reliability. Its ultra-heavy load capacity allows for the design of more compact machinery, as a single guide can often replace larger or multiple standard guides. The high rigidity ensures minimal deflection under load, which is critical for maintaining precision in machining, assembly, and measurement processes. The low friction and smooth motion contribute to higher positional accuracy, repeatability, and energy efficiency. The longevity offered by the caged ball design reduces maintenance frequency and total cost of ownership, minimizing machine downtime.

Typical applications for this heavy-duty linear guide are found in sectors where failure is not an option. In industrial machinery, it is indispensable for heavy-duty CNC machining centers, large-scale milling machines, high-precision grinding machines, and injection molding machines that require unwavering stability during high-force operations. Within the automotive industry, it is deployed in automated welding systems, heavy-duty robotic arms for part handling and assembly, and large stamping presses. For precision equipment, the SVS C SERIES provides the foundational stability for semiconductor manufacturing apparatus, such as steppers and wafer handlers, and large-scale coordinate measuring machines (CMMs) where thermal stability and minimal deflection are paramount to achieving micron-level accuracies.

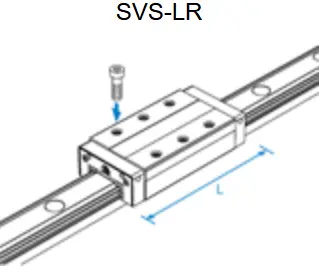

The THK LM Guide Caged Ball LM Guide Ultra Heavy Load (4-Way) Model SVS/SVS LR SERIES represents a pinnacle of engineering for applications demanding exceptional load capacity, rigidity, and precision under the most strenuous operating conditions. This series is specifically designed as a 4-way equal load ball recirculating linear guide, which fundamentally means it can handle loads of identical magnitude from all four primary directions—radial, reverse radial, and lateral. This inherent symmetry in load-bearing capability is a core differentiator, providing unparalleled stability and resistance to complex moment forces that would compromise the performance of standard guides.

At the heart of its robust performance is the innovative caged ball technology. Unlike conventional linear guides where balls can contact each other during recirculation, the SVS/SVS LR SERIES incorporates a precision-engineered resin retainer, or cage, that separates each ball. This design eliminates ball-to-ball contact, drastically reducing friction, heat generation, and wear. The result is a dramatic enhancement in operational smoothness and a significant extension of service life, even at high speeds and under heavy loads. The series is further characterized by its high rigidity, achieved through an optimized contact angle and a large ball diameter relative to the groove size. This construction ensures minimal elastic deformation under load, guaranteeing exceptional positional accuracy and repeatability. For maintenance and operational efficiency, these units are available in both standard lubrication and pre-lubricated, sealed, and lubricated types (SVS LR), offering long-term reliability and reduced maintenance intervals.

The performance advantages of the SVS/SVS LR SERIES translate directly into superior application outcomes. Its ultra-heavy load capacity makes it indispensable in heavy-duty industrial machinery, such as large-scale machining centers for milling and boring, where it provides the foundational stability for massive workpieces and powerful cutting forces. In the automotive industry, this series is the component of choice for critical automation systems, including heavy-duty robotic welding arms, large transfer lines that move engine blocks and chassis components, and high-precision stamping presses. The combination of high rigidity and caged ball smoothness ensures that these automated processes maintain precise alignment and repeatability over millions of cycles, maximizing throughput and quality. Furthermore, in the realm of precision equipment, the guide's ability to resist moment loads and maintain accuracy under load is critical for semiconductor manufacturing apparatus, large-scale coordinate measuring machines (CMMs), and advanced optical alignment systems. By delivering unwavering precision, immense strength, and exceptional durability, the THK SVS/SVS LR SERIES establishes itself as an enabling technology for the most demanding motion control challenges across global industries.

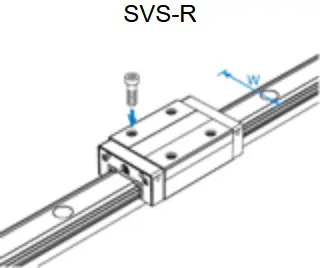

THK's LM Guide Caged Ball LM Guide Ultra Heavy Load (4-Way) Model SVS/SVS R SERIES represents a significant advancement in linear motion technology, engineered specifically for applications demanding exceptional load capacity, rigidity, and precision under the most challenging industrial conditions. This series incorporates a unique caged ball design where precision balls are securely held within a resin retainer, effectively eliminating metal-to-metal contact between the balls. This innovation drastically reduces friction, heat generation, and torque variation, while simultaneously preventing the balls from falling out during handling or maintenance, ensuring easier assembly and enhanced operational reliability.

The technical features of the SVS/SVS R SERIES are defined by its robust construction and specialized geometry. The "4-way equal load" design is a cornerstone of its performance, meaning the guide can handle identical load capacities in all four primary directions: radial, reverse radial, and lateral. This is achieved through a Gothic arch groove raceway design that provides a large contact area between the balls and the raceways. The components are manufactured from high-carbon chromium bearing steel, subjected to rigorous heat treatment to attain a superior surface hardness, which guarantees exceptional wear resistance and a long, maintenance-free service life. The inclusion of seals and scrapers at both ends effectively shields the critical raceway areas from contaminants like dust, chips, and moisture, making these guides exceptionally suitable for harsh environments.

Performance advantages are immediately evident in operational settings. The caged ball system ensures smooth, consistent motion with remarkably low and stable friction, which translates to higher precision, improved positional accuracy, and reduced energy consumption. The ultra-high rigidity allows these guides to withstand substantial moment loads and heavy static/ dynamic forces without deformation, ensuring stability and accuracy even during high-speed, high-load operations. This combination of high load capacity, rigidity, and smooth motion directly contributes to increased machine throughput, enhanced product quality, and reduced total cost of ownership through minimal maintenance and extended component lifespan.

Typical applications for the THK SVS/SVS R SERIES are found in sectors where failure is not an option. In industrial machinery, they are indispensable in heavy-duty machining centers, large-scale transfer lines, injection molding machines, and precision grinding equipment, where they provide the foundational stability for heavy workpieces and cutting forces. Within automotive manufacturing systems, these guides are deployed in robotic welding arms, heavy-duty press automation, and vehicle assembly line transporters, handling high payloads with unwavering precision. For precision equipment, they serve critical roles in semiconductor manufacturing apparatus, large-format precision measuring machines, and aerospace component fabrication systems, where their vibration damping characteristics and micron-level accuracy are paramount. The SVS/SVS R SERIES is, therefore, not merely a component but a fundamental enabler of productivity, reliability, and precision in the most demanding mechanical systems.