The THK LM Guide Caged Ball LM Guide Ultra Heavy Load (Radial Type) Model SVR, SVR LCH, and SERIES represents a pinnacle in linear motion technology, engineered specifically for applications demanding exceptional load capacity, rigidity, and precision under the most strenuous operating conditions. This series is distinguished by its innovative caged ball design, where precision balls are meticulously contained and separated by a robust polymer retainer. This fundamental architecture eliminates metal-to-metal contact between the balls, drastically reducing friction, heat generation, and torque variation. The radial-type load direction is optimized to support immense forces perpendicular to the shaft axis, making it the ideal solution for ultra-heavy-load scenarios where standard guides would falter.

Key technical features define the superior performance of this series. The incorporation of the caged ball system is paramount, as it prevents ball-to-ball friction, ensuring smooth, consistent motion and significantly extending service life by minimizing wear and the need for lubrication. The guide rails and blocks are manufactured from high-carbon chromium bearing steel, subjected to rigorous heat treatment processes to achieve an exceptionally high surface hardness. This results in outstanding resistance to denting, brinelling, and fatigue, even under repeated shock loads. For enhanced corrosion resistance in challenging environments, the SVR LCH variant features a specialized LM slat seal and an anti-corrosive coating, ensuring long-term reliability. The series is designed with high rigidity, maintaining geometric accuracy and stability under multi-directional loads, which is critical for preserving precision.

The performance advantages are immediately apparent in operational efficiency and longevity. The dramatic reduction in friction translates directly to lower driving force requirements, enabling the use of smaller, more energy-efficient motors and drives. The stable, low-friction motion ensures exceptional positional accuracy and smooth travel with minimal vibration, which is crucial for high-precision tasks. The extended lubrication intervals, a direct benefit of the caged ball design, reduce maintenance downtime and total cost of ownership. Furthermore, the ability to withstand ultra-heavy loads without compromising precision or structural integrity allows for more compact machine designs, as a single SVR guide can often replace bulkier or multiple standard guides.

Typical applications for the THK SVR series are found in industries where brute force and pinpoint accuracy must coexist. In industrial machinery, it is indispensable for the vertical axes of heavy-duty machining centers, large-scale transfer lines, injection molding machines clamping units, and precision grinding equipment. Within the automotive manufacturing sector, these guides are deployed in massive robotic welding arms, heavy-part positioning systems, and stamping press feeders. In the realm of precision equipment, they provide the robust yet smooth motion required for large-format semiconductor manufacturing systems, precision optical assembly stages, and advanced material testing machines that subject components to extreme forces. The THK LM Guide Caged Ball SVR Series thus stands as a critical enabler of productivity, reliability, and precision in the world's most demanding mechanical applications.

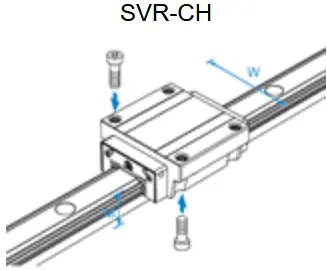

The THK LM Guide Caged Ball LM Guide Ultra Heavy Load (Radial Type) Model SVR/SVR CH SERIES represents a significant advancement in linear motion technology, engineered specifically to withstand extreme loads while maintaining precision and durability. This series incorporates a unique caged ball design where the recirculating steel balls are separated and guided by a robust polymer cage. This configuration drastically reduces friction, minimizes heat generation, and virtually eliminates metal-to-metal contact between the balls, leading to exceptionally smooth motion, enhanced lubrication retention, and a substantial increase in operational life compared to standard ball-based linear guides. The radial-type load arrangement is optimized to support exceptionally high loads perpendicular to the mounting surface, making it an ideal solution for applications demanding immense static and dynamic load capacity.

Key technical features define the superior performance of the SVR/SVR CH SERIES. The caged ball mechanism is central to its design, preventing ball-to-ball friction and ensuring consistent, quiet operation even at high speeds. The guide rails and blocks are manufactured from high-carbon chromium bearing steel, subjected to rigorous heat treatment processes to achieve superior hardness and wear resistance. For enhanced corrosion resistance in challenging environments, options with stainless steel components are available. The series is designed with optimized groove profiles and a high ball count within the cage structure, which distributes the load over a larger surface area, dramatically increasing its load-carrying capacity. Sealing systems are highly effective, incorporating multi-layer contact seals and metal scrapers to provide comprehensive protection against contaminants like dust, chips, and moisture, ensuring reliability in dirty or wash-down conditions.

The performance advantages are substantial, directly addressing the needs of heavy-duty automation. The ultra-high load capacity allows for the design of more compact machinery, as a single SVR/SVR CH guide can often replace larger or multiple standard guides. The caged ball design results in a more consistent and predictable coefficient of friction, which contributes to improved positional accuracy and smooth velocity control. This stability is critical for precision machining and assembly tasks. Furthermore, the reduction in friction and wear translates to lower maintenance requirements, less frequent lubrication intervals, and a longer total service life, reducing the total cost of ownership.

Typical applications for this robust series are found in industries where reliability under extreme stress is non-negotiable. In industrial machinery, it is extensively used in heavy-duty machining centers for supporting massive milling heads, in large-scale injection molding machines for ejector and moving platen systems, and in precision grinding machines requiring unwavering stability. Within the automotive manufacturing sector, these guides are integral to heavy-duty robotic welding arms, large stamping press transfers, and automated assembly lines handling powertrain components. In the realm of precision equipment, the SVR/SVR CH SERIES provides the foundational stability for large-scale coordinate measuring machines (CMMs), semiconductor fabrication equipment like steppers, and high-capacity optical positioning systems, where precision must be maintained under significant load.

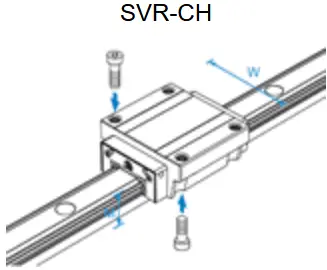

The THK LM Guide Caged Ball LM Guide Ultra Heavy Load (Radial Type) Model SVR, SVR-LRH, and SERIES represents a significant advancement in linear motion technology, engineered specifically to withstand extreme loads while maintaining precision and durability. This series incorporates a unique caged ball design where precision balls are separated and guided by a robust polymer cage, effectively eliminating metal-to-metal contact between the balls. This fundamental design principle drastically reduces friction, minimizes heat generation, and virtually eliminates the risk of ball smearing, even under the most demanding ultra-heavy load conditions. The radial-type configuration ensures optimal load distribution directly through the ball grooves, making it exceptionally suited for applications involving substantial radial forces.

Key technical features define the superior performance of this series. The caged ball structure is central to its operation, facilitating smoother motion and significantly extending operational life by preventing ball-to-ball friction and the associated wear. These guides are constructed from high-grade steel, subjected to rigorous heat treatment processes to achieve exceptional surface hardness and core toughness, which is critical for resisting deformation under heavy loads. The SVR-LRH variant often includes integrated seals or scrapers, providing enhanced protection against contaminants like dust, chips, and moisture, thereby ensuring reliability in harsh industrial environments. Pre-load adjustments are precisely engineered to eliminate internal clearance, resulting in high rigidity, exceptional positional accuracy, and minimal deflection when subjected to moment loads.

The performance advantages are substantial and directly address the challenges of heavy-duty automation. The reduction in friction translates to lower driving force requirements, allowing for the use of smaller, more energy-efficient motors and drives. The high rigidity and load capacity enable these guides to support massive components and tools without compromising on smooth, precise linear travel. This combination results in improved machining accuracy, higher system stability, reduced maintenance intervals, and a dramatically longer service life compared to conventional linear guides. The inherent reliability of the design minimizes unplanned downtime, a critical factor in high-volume production settings.

Typical applications for the THK SVR, SVR-LRH, and SERIES are found in sectors where reliability under extreme stress is non-negotiable. In industrial machinery, they are indispensable in large-scale machining centers, heavy-duty grinding machines, injection molding machines, and press feeds, where they guide slides and tables carrying substantial weight and resisting significant cutting forces. Within the automotive industry, these components are integral to automated welding systems, heavy-duty robotic arms for part handling, and precision assembly lines for engines and transmissions. In the realm of precision equipment, they provide the stable and rigid foundation required for large-format semiconductor manufacturing equipment, precision inspection and measuring machines, and other specialized automation systems that demand unwavering accuracy under continuous, high-load operation.

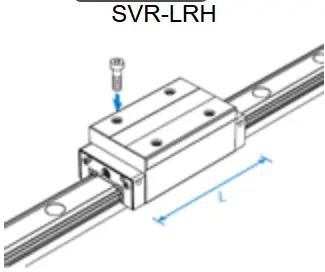

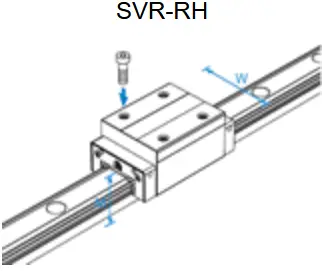

The THK LM Guide Caged Ball LM Guide Ultra Heavy Load (Radial Type) Model SVR, SVR RH, and SERIES represents a significant advancement in linear motion technology, engineered specifically for applications demanding exceptional load capacity, rigidity, and precision under the most challenging operational conditions. This series incorporates a unique caged ball design, where precision balls are securely retained and guided by a robust polymer cage. This fundamental design element is critical, as it prevents ball-to-ball contact, drastically reducing friction, heat generation, and torque variation. The result is a smoother, more consistent motion with significantly lower noise levels compared to conventional retainer-type linear guides, even at high speeds.

Core technical features define the superior performance of this series. Its radial-type load design is optimized to support ultra-heavy loads directly perpendicular to the mounting surface, making it exceptionally stable under substantial force. The incorporation of THK's patented "Caged Ball" technology is paramount; by isolating the recirculating balls, it eliminates the sliding friction inherent in standard designs, leading to a dramatic reduction in wear and a substantial increase in operational lifespan. Furthermore, the series is available in various accuracy grades and preload levels, allowing for precise tuning to match specific application requirements for rigidity and positional accuracy. Sealing systems are also highly effective, employing multi-lip seals and scrapers to provide comprehensive protection against contaminants like dust, chips, and moisture, ensuring reliability in harsh industrial environments.

The performance advantages are substantial and directly address the needs of heavy-duty automation. The combination of the caged ball system and optimized raceway geometry results in a remarkably high static and dynamic load rating, enabling the guide to handle immense weights without compromising structural integrity or precision. The reduced friction directly translates to lower driving force requirements, enhancing energy efficiency and allowing for the use of smaller, more cost-effective motors and drives. The exceptional rigidity minimizes elastic deformation under load, guaranteeing high positional accuracy and repeatability, which is crucial for precision machining and assembly processes. This durability and precision ensure long-term, maintenance-free operation, reducing total cost of ownership.

Typical applications for the THK SVR/SERIES are found wherever robust, reliable linear motion is non-negotiable. In industrial machinery, it is indispensable for heavy-duty CNC machining centers, large-scale transfer lines, injection molding machines, and precision grinding equipment, where it provides the stable foundation for high-precision cutting and forming operations. Within automotive manufacturing systems, these guides are deployed in robotic welding arms, heavy-duty palletizers, stamping press automation, and vehicle assembly conveyors, handling massive components with unwavering accuracy. In the realm of precision equipment, they facilitate movement in large-scale semiconductor manufacturing apparatus, precision inspection and measuring machines, and advanced aerospace assembly jigs, where their ability to maintain precision under extreme load is paramount.

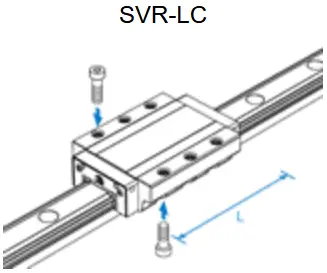

The THK LM Guide Caged Ball LM Guide Ultra Heavy Load (Radial Type) Model SVR, SVR LC, and SERIES represents a pinnacle of engineering for applications demanding exceptional load capacity, rigidity, and precision under the most severe operating conditions. This series is specifically engineered to manage ultra-heavy loads and moments with unparalleled stability, making it an indispensable component in heavy-duty industrial automation, large-scale machining, and high-precision assembly systems.

Technically, the series is distinguished by its caged ball design. Unlike conventional linear guides where recirculating balls can contact each other, the SVR/SERIES incorporates a precision-engineered retainer (cage) that separates each ball. This fundamental design innovation eliminates ball-to-ball contact, drastically reducing friction, heat generation, and wear. The result is a dramatic improvement in operational smoothness and a significant extension of service life, even at high speeds. The radial-type load direction is optimized to support massive vertical and radial forces directly, ensuring minimal deformation under load. The components are manufactured from high-grade chromium steel and subjected to rigorous heat treatment processes, yielding a surface hardness that maximizes resistance to brinelling and fatigue. The SVR LC variant further enhances performance with a specialized seal configuration that provides superior defense against contaminants like chips, dust, and coolant, which is critical for maintaining precision in dirty machining environments.

The performance advantages are substantial and directly address the challenges of heavy-load applications. The primary benefit is its exceptional load-carrying capacity, which can be several times greater than that of standard ball-type linear guides. This is coupled with extremely high rigidity, which minimizes deflection and ensures positional accuracy is maintained even under extreme static and dynamic loads. The caged ball system not only prolongs life but also enables more consistent, smooth motion with lower and more stable friction coefficients, reducing the torque required for actuation and contributing to energy efficiency. The design's ability to handle high moment loads (pitch, yaw, and roll) makes it exceptionally stable, preventing guide block skewing and ensuring reliable, repeatable motion.

Typical applications for the SVR/SERIES are found wherever massive loads and precision must coexist. In industrial machinery, it is the guiding element of choice for heavy-duty CNC machining centers, large boring mills, and high-payload industrial robots used in welding and material handling. Within the automotive manufacturing sector, these guides are integral to massive stamping presses, robotic assembly lines for vehicle bodies and powertrains, and precision testing equipment. In the realm of precision equipment, they provide the stable foundation for large-scale semiconductor manufacturing systems, precision optical grinding machines, and high-capacity coordinate measuring machines (CMMs). Its robust construction and reliability make it a critical component for ensuring uptime and precision in the most demanding industrial applications.

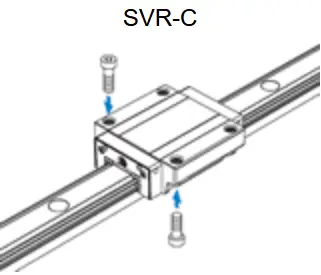

The THK LM Guide Caged Ball LM Guide Ultra Heavy Load (Radial Type) Model SVR/SVR C SERIES represents a significant advancement in linear motion technology, engineered specifically for applications demanding exceptional load capacity, rigidity, and precision under the most challenging operational conditions. This series incorporates a unique caged ball design, where precision balls are meticulously retained and guided by a robust polymer cage. This fundamental design element is critical, as it prevents ball-to-ball contact, drastically reducing friction, heat generation, and torque variation. The result is a smoother, more consistent motion with a significantly longer operational life compared to conventional linear guides.

Technically, the SVR/SVR C SERIES is distinguished by its radial-type load reception, optimized to support ultra-heavy loads directly perpendicular to the mounting surface. This is achieved through a combination of a high-rigidity, large-diameter track rail and a slider block engineered with a high-capacity, multi-row circular arc groove raceway. The caged ball system ensures that even at high speeds or under moment loads, the balls circulate smoothly without skewing, maintaining constant contact for superior accuracy and minimal vibration. The series is available with various preload levels, allowing for fine-tuning to achieve the optimal balance between stiffness and smoothness for a specific application. Sealing is another critical feature; integrated high-performance seals effectively shield the recirculating balls and raceways from contaminants like dust, chips, and moisture, ensuring reliability in harsh environments and reducing maintenance intervals.

The performance advantages of this design are substantial. The primary benefit is its unparalleled load-carrying capacity, which enables the use of more compact linear systems in place of bulkier, less efficient alternatives, saving valuable space and weight in machine design. The caged ball technology directly translates to higher permissible speeds, lower noise levels, and exceptional positional accuracy and repeatability. The reduced friction not only conserves energy but also minimizes heat generation, which is crucial for applications requiring thermal stability. Furthermore, the enhanced lubrication retention within the cage structure promotes long-term reliability and reduces the frequency of lubrication maintenance.

These characteristics make the SVR/SVR C SERIES ideally suited for a wide range of demanding industrial applications. In heavy-duty industrial machinery, it is the component of choice for high-precision machining centers, heavy-duty turning mills, and large-scale transfer lines where resisting heavy cutting forces and maintaining table flatness are paramount. Within the automotive manufacturing sector, these guides are deployed in robotic welding arms, heavy-part positioning systems, and stamping press feeds, where they provide the durability and precision needed for high-volume production. In the realm of precision equipment, the series finds application in semiconductor manufacturing apparatus, large-format coordinate measuring machines (CMMs), and advanced optical positioning systems, where its stability and accuracy are essential for micron-level tolerances. The THK SVR/SVR C SERIES thus stands as a foundational component for engineers designing next-generation machinery that requires a fusion of brute strength and refined precision.

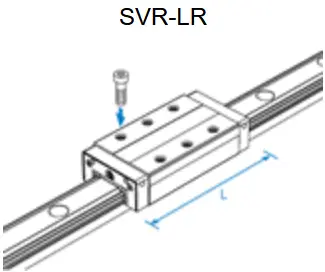

The THK LM Guide Caged Ball LM Guide Ultra Heavy Load (Radial Type) Model SVR, SVR-LR, and SERIES represents a pinnacle in linear motion technology, engineered specifically to withstand extreme loading conditions while maintaining precision and durability. These guides incorporate a unique caged ball retainer system that fundamentally enhances performance by preventing direct ball-to-ball contact, drastically reducing friction, heat generation, and torque fluctuations. This design is crucial for applications demanding smooth, consistent motion under substantial radial loads. The series is characterized by its robust construction, featuring a radial-type load path that optimally distributes forces, making it exceptionally suited for ultra-heavy load scenarios where standard linear guides would falter.

Key technical features include the caged ball design, which not only minimizes wear and maintenance but also allows for higher speeds and accelerations by controlling ball circulation efficiently. The guides are pre-loaded to eliminate backlash, ensuring high rigidity and positional accuracy even under varying load conditions. They are available in various sizes and configurations, such as the SVR (standard type) and SVR-LR (low-profile type), to accommodate different spatial and load requirements. Sealing systems are integrated to protect against contaminants like dust, chips, and moisture, extending service life in harsh environments. Additionally, these models offer easy installation and alignment, thanks to precision-machined reference surfaces and optional accessories like wipers and grease nipples for simplified upkeep.

Performance advantages are substantial, starting with an extended operational lifespan due to reduced wear on balls and raceways. The low friction coefficient translates to higher efficiency, requiring less drive power and reducing energy consumption. Smooth motion characteristics minimize vibration and noise, which is critical in precision applications. The high load capacity—supporting radial loads significantly beyond conventional guides—ensures reliability in demanding setups, while the rigidity provides stability that enhances machining or positioning accuracy. These attributes make the series ideal for continuous, high-duty cycles without compromising performance.

Typical applications span industries where heavy loads and precision intersect. In industrial machinery, they are deployed in large machining centers, heavy-duty CNC equipment, and press feeds, where they handle substantial forces during metal cutting or forming operations. Automotive systems utilize them in robotic welding arms, assembly line transporters, and testing rigs that require robust support for repetitive, high-stress movements. In precision equipment, they serve in semiconductor manufacturing apparatus, optical alignment systems, and medical imaging devices, where smooth, accurate linear motion is non-negotiable. Overall, the THK SVR SERIES delivers a reliable solution for applications prioritizing load capacity, longevity, and precision in challenging operational environments.

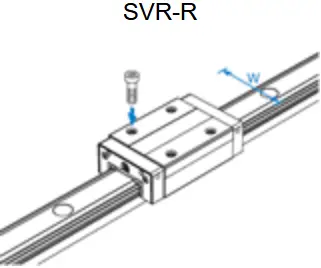

THK's SVR/SVR R Series LM Guide represents a significant advancement in linear motion technology, specifically engineered to manage ultra-heavy loads with exceptional radial rigidity. This caged ball LM guide system is designed for applications where standard linear guides would be compromised by extreme forces, offering a robust solution that maintains precision under demanding conditions. The fundamental innovation lies in its caged ball retainer mechanism, which fundamentally alters the operational dynamics compared to conventional designs.

The technical foundation of the SVR/SVR R Series centers on its unique ball circulation system. A polymer cage securely retains the precision balls, preventing direct ball-to-ball contact during operation. This design eliminates the friction and heat generation typically associated with recirculating ball systems, resulting in smoother motion, significantly reduced operational noise, and enhanced lubrication retention. The cage maintains consistent ball spacing, ensuring uniform load distribution across all rolling elements. This construction allows for dramatically increased load capacities—both static and dynamic—while maintaining the high positional accuracy THK systems are known for. The radial-type configuration provides superior resistance to moment loads and overturning forces, making it particularly suitable for applications where heavy components create substantial tipping moments.

Performance advantages extend beyond mere load capacity. The elimination of ball-to-ball contact reduces wear on critical components, substantially extending service life even under continuous heavy-load operation. The maintained lubrication within the raceways ensures consistent performance over extended periods, reducing maintenance frequency and total cost of ownership. The design also accommodates preloading options that minimize deflection under load, providing exceptional stiffness for precision positioning applications. These guides deliver high accuracy with minimal variation in running parallelism, essential for applications requiring precise linear movement under substantial weight.

Typical applications span multiple industries where heavy loads and precision must coexist. In industrial machinery, these guides are indispensable for large machining centers performing heavy-duty milling operations, where they support massive workpieces while maintaining cutting accuracy. They're equally critical in injection molding machines, where they guide the substantial forces involved in mold clamping mechanisms. Within automotive manufacturing systems, SVR/SVR R Series guides provide the structural backbone for automated welding lines handling vehicle frames and body panels, robotic positioning systems managing heavy components, and precision assembly equipment for powertrain components. The series also serves precision equipment applications including large-scale coordinate measuring machines, semiconductor manufacturing equipment handling heavy vacuum chambers, and specialized medical imaging devices where both precision and load capacity are non-negotiable requirements.