The THK LM Guide Caged Ball LM Guide Wide Rail Model SHW SHW CRHR SERIES represents a significant advancement in linear motion technology, engineered to deliver unparalleled precision, rigidity, and longevity in demanding industrial environments. This series incorporates a unique caged ball design where precision steel balls are retained and guided by a polymer cage, effectively eliminating metal-to-metal contact between the balls. This innovation drastically reduces friction, heat generation, and the need for frequent lubrication, while simultaneously preventing torque fluctuations and ensuring exceptionally smooth, consistent motion. The wide rail configuration provides a larger mounting surface and a more substantial cross-section, resulting in a dramatically higher moment load capacity and superior resistance to overturning moments, vibration, and shock loads.

Key technical features define the performance envelope of the SHW CRHR series. The caged ball mechanism is central to its advantages, as it minimizes ball-to-ball friction and wear, leading to a substantial increase in operational life and maintaining high accuracy over extended periods. The wide rail design enhances system rigidity, which is critical for applications requiring high positional accuracy and repeatability. These guides are available with various preload options, allowing for precise tuning to match specific application requirements for stiffness and backlash elimination. Furthermore, the integrated seals and wipers are highly effective at excluding contaminants like dust, chips, and moisture, making the series exceptionally suitable for harsh operating conditions. The design also facilitates easier installation and maintenance, contributing to reduced machine downtime.

The performance advantages of the SHW CRHR series translate directly into tangible benefits for machinery and equipment. Its high rigidity and load capacity enable it to support heavy loads with minimal deflection, which is essential for maintaining precision under load. The low-friction, caged ball system ensures smooth, quiet, and low-vibration operation, contributing to higher quality finished products and a better working environment. The extended service life and reduced maintenance requirements significantly lower the total cost of ownership.

These characteristics make the THK SHW CRHR series ideal for a wide spectrum of demanding applications. In industrial machinery, it is extensively used in heavy-duty machining centers, grinding machines, and milling equipment where high cutting forces and precision are paramount. Within automotive manufacturing systems, these guides are found in high-speed transfer lines, robotic welding arms, and precision assembly stations that demand robustness and reliability. In the realm of precision equipment, the SHW CRHR is a critical component in semiconductor manufacturing apparatus, inspection and measurement machines, and medical imaging devices, where flawless, smooth motion and long-term accuracy are non-negotiable. Its robust design ensures dependable performance, enhancing productivity and reliability across these critical sectors.

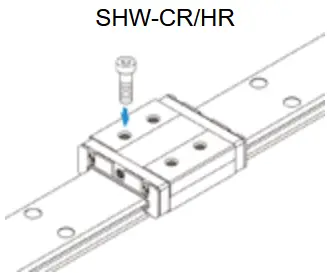

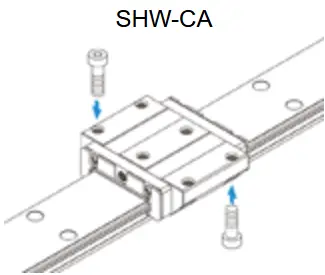

THK's LM Guide Caged Ball LM Guide Wide Rail Model SHW and SHW CA SERIES represent a significant advancement in linear motion technology, engineered to deliver exceptional load capacity, rigidity, and precision in demanding industrial environments. These guides feature a unique caged ball design where precision balls are retained and separated by a robust cage, effectively minimizing friction, reducing heat generation, and eliminating ball-to-ball contact. This design drastically lowers torque variation and ensures smooth, consistent motion even under high loads and rapid traversal speeds. The wide rail configuration provides a larger contact area, significantly enhancing moment load capacity and overall system stability. Available in both standard (SHW) and center rail (SHW CA) types, the series offers flexibility in mounting and load distribution to suit diverse application requirements.

Key technical features include the incorporation of THK's patented Caged Ball technology, which not only improves lubrication retention for prolonged maintenance intervals but also prevents recirculation issues common in conventional designs. The guides are constructed from high-grade steel, subjected to rigorous heat treatment processes to achieve superior surface hardness and wear resistance. Precision grinding of raceway profiles ensures optimal ball contact, resulting in high positional accuracy and repeatability. Sealing systems are comprehensively designed with multiple seals and scrapers to effectively exclude contaminants like dust, chips, and moisture, making them suitable for harsh operating conditions. Standard lubrication units facilitate easy re-lubrication, further enhancing service life and reliability.

Performance advantages are substantial, starting with a dramatic increase in permissible load capacity—up to twice that of conventional ball guides in some configurations—enabling the use of more compact systems without sacrificing strength. The rigidity of the wide rail design minimizes deflection under moment loads, ensuring precise alignment and reduced vibration, which is critical for machining accuracy. Smooth motion characteristics lead to lower noise levels and reduced energy consumption, contributing to quieter and more efficient operations. Extended service life is achieved through reduced wear and effective contamination protection, lowering total cost of ownership by minimizing downtime and maintenance needs.

Typical applications span across sectors requiring robust and precise linear motion. In industrial machinery, these guides are integral to high-speed machining centers, heavy-duty CNC milling machines, and precision grinding equipment where high load capacity and rigidity are paramount. Within automotive manufacturing systems, they are employed in robotic welding arms, automated assembly lines, and precision testing apparatus that demand reliability under continuous operation. For precision equipment, the SHW and SHW CA SERIES are found in semiconductor manufacturing tools, optical positioning stages, and medical device automation, where smooth, accurate motion is essential for product quality and process consistency. Their versatility and durability make them a preferred choice for engineers seeking to enhance performance in applications ranging from general automation to specialized high-precision industries.