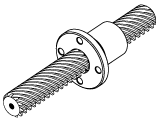

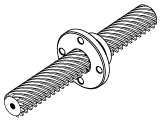

THK's Change Nut Model DCMA and DCMB SERIES represent a specialized category of linear motion components engineered for applications requiring periodic or rapid replacement of ball screw nuts without disassembling the entire system. These change nuts are designed with a split structure, allowing for straightforward removal and installation while the ball screw remains in place. This design significantly reduces maintenance downtime and operational costs in machinery where nut wear or damage is a recurring issue. The DCMA and DCMB models are built to exacting standards, ensuring compatibility with a wide range of ball screw sizes and configurations, and they are available in various precision grades to meet diverse application demands.

Key technical features of the DCMA and DCMB SERIES include their robust construction from high-grade steel, which provides excellent wear resistance and durability under high-load conditions. The nuts incorporate THK's advanced ball circulation technology, ensuring smooth and precise motion with minimal friction. They feature a compact design that saves space in machinery layouts, and their split mechanism allows for quick replacement without specialized tools. Additionally, these change nuts are pre-loaded to eliminate backlash, enhancing positional accuracy and repeatability in dynamic applications. Sealing options are available to protect against contaminants like dust and moisture, extending service life in harsh environments.

Performance advantages of these change nuts are substantial. By enabling swift nut replacement, they minimize machine downtime in production lines, boosting overall efficiency. Their high load capacity and rigidity support heavy-duty operations, while the precision engineering reduces vibration and noise, contributing to smoother machine performance. The ability to replace the nut without removing the ball screw simplifies maintenance routines, reducing labor costs and the risk of assembly errors. This makes them ideal for industries where continuous operation is critical, such as automotive manufacturing or precision equipment assembly.

Typical applications for the DCMA and DCMB SERIES are widespread across industrial machinery, automotive systems, and precision equipment. In industrial settings, they are used in CNC machine tools, injection molding machines, and material handling systems, where frequent nut wear occurs due to high-cycle operations. Automotive applications include robotic welding arms, assembly line conveyors, and testing equipment that demand reliable linear motion with minimal maintenance interruptions. In precision equipment, these change nuts are employed in semiconductor manufacturing devices, optical positioning systems, and medical instrumentation, where accuracy and cleanliness are paramount. Their versatility and ease of use make them a go-to solution for enhancing the reliability and longevity of linear motion systems in demanding environments.

The THK Change Nut Model DCMA and DCMB series represent a specialized class of recirculating ball screw nuts engineered for rapid replacement and minimal machine downtime. These components are designed as consumable parts within larger linear motion systems, acknowledging that the nut is typically the first element to wear out. The core design principle facilitates a straightforward exchange without requiring the disassembly of the entire ball screw assembly or the realignment of associated support units. This is achieved through a standardized outer cylindrical profile and precise dimensional tolerances, ensuring direct interchangeability with existing mounts.

Technically, the DCMA and DCMB series are distinguished by their internal ball circulation system and high-grade bearing steel construction. They feature a compact, single-nut design with a deflector-type ball return system that ensures smooth, consistent recirculation of the precision balls. This minimizes vibration and noise while providing high rigidity and accurate motion transfer. The nuts are pre-loaded to eliminate axial play, delivering high positional accuracy and repeatability. A critical performance feature is the integrated wiper seal, which effectively excludes contaminants like dust and chips while retaining the necessary grease lubrication. This significantly extends the service life of both the nut and the mating ball screw by preventing abrasive wear.

The performance advantages are most evident in operational efficiency and total cost of ownership. The primary benefit is the drastic reduction in maintenance time and labor costs. When wear is detected, a machine operator can simply unbolt the old nut and install a new one from the DCMA or DCMB series, returning the equipment to service in a fraction of the time required for a full ball screw replacement. This design also protects the more expensive ball screw shaft from damage, as it remains installed and undisturbed during the nut change. Consequently, machine availability is maximized, and lifecycle costs are lowered.

Typical applications for the THK Change Nut Nut are found in high-duty-cycle industrial environments where uptime is critical. In industrial machinery, they are extensively used in the feed axes of CNC machining centers, CNC lathes, and high-speed milling machines, where continuous and precise tool positioning is paramount. Within automotive manufacturing systems, these nuts are ideal for robotic welding arms, material handling gantries, and automated assembly line transfers that operate multiple shifts. In the realm of precision equipment, they provide reliable motion for semiconductor wafer handling robots, precision measuring instruments, and optical positioning stages. Their design is a direct response to the need for maintainability and reliability in automated systems that form the backbone of modern manufacturing.