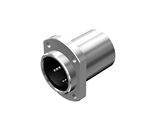

THK's LMK Series flanged-type linear bushings represent a significant advancement in linear motion technology, combining the reliability of the ball bushing concept with enhanced mounting stability. These Square Flange Model LMK units feature a compact, square-shaped flange with four precision-machined mounting holes, allowing for secure and straightforward installation onto machine frames, slides, or other structural components. The flange design provides excellent resistance to torque and moment loads, ensuring maintained alignment under demanding operational conditions. Constructed from high-carbon chromium bearing steel (SUJ2 equivalent) with a precise inner ring geometry, the bushings undergo specialized heat treatment to achieve optimal surface hardness and core toughness, resulting in extended service life and consistent performance.

Key technical features include a patented retainer design that prevents ball-to-ball contact, minimizing friction, heat generation, and wear even during high-speed or high-frequency reciprocating motions. The precision-ground outer surface and flange faces ensure perpendicularity and parallelism, critical for accurate linear guidance. Seals integrated into both ends of the bushing effectively exclude contaminants such as dust, chips, and moisture while retaining lubrication, making the LMK suitable for environments where debris is present. The ball recirculation system ensures smooth, nearly frictionless motion with minimal variation in torque, contributing to precise positioning and repeatability.

Performance advantages of the LMK flanged linear bushings are evident in their high load capacity, achieved through an optimized contact angle between the balls and the raceway. This design supports substantial radial loads while accommodating moderate moment loads, reducing the need for additional support elements in many applications. The low coefficient of friction translates to higher efficiency, allowing for smaller drive motors and reduced energy consumption. Maintenance requirements are minimal due to the effective sealing and long-term lubrication retention, leading to decreased downtime and lower total cost of ownership.

Typical applications span across various industries where precision, reliability, and compact design are paramount. In industrial machinery, LMK bushings are commonly employed in CNC machining centers for tool changer mechanisms, automated assembly lines for linear slides, and packaging equipment for product positioning systems. Within automotive manufacturing, they facilitate precise movement in robotic welding arms, engine component testing fixtures, and brake system assembly stations. For precision equipment, these components are integral to optical alignment devices, semiconductor wafer handling robots, and medical imaging system gantries, where smooth, accurate motion is critical to operational success. The versatility and robustness of the THK LMK Series make it a preferred choice for engineers seeking to enhance the performance and longevity of their linear motion systems.

The THK Guide Ball Bushing Linear Bushing, specifically the flanged type Square Flange Model LMIK, represents a high-performance linear motion component engineered for applications demanding rigidity, precision, and durability. This unit is a compact, flanged linear bushing featuring a square outer flange profile, which facilitates straightforward and secure mounting onto machine surfaces, brackets, or structural members using standard fasteners. The internal design incorporates a precision-engineered ball recirculation system, where high-grade steel balls circulate smoothly along hardened raceways, providing low-friction linear guidance for a shaft or rod. This recirculation mechanism ensures consistent motion, minimal stick-slip, and high positional accuracy.

Key technical features define the LMIK model's capabilities. Its square flange design offers a large, stable mounting surface, significantly enhancing moment load capacity and resistance to tilting forces compared to non-flanged or round-flanged alternatives. The bushing itself is constructed from high-carbon chromium bearing steel, hardened and precision-ground to exacting tolerances for long-term dimensional stability and wear resistance. A critical feature is the inclusion of seals or shields, which effectively prevent the ingress of contaminants such as dust, chips, and moisture, while retaining the essential grease lubrication within the ball circuit. This sealed design is vital for maintaining performance and extending service life in harsh operating environments. The compact cross-section of the LMIK allows for space-saving machine designs without compromising on load-bearing capacity or stroke length.

The performance advantages of this component are substantial. It delivers exceptionally smooth and quiet linear motion with a consistently low coefficient of friction, which translates to reduced drive power requirements and higher energy efficiency. The high rigidity afforded by the square flange and robust construction ensures minimal deflection under load, directly contributing to improved machining or positioning accuracy. Its durability and sealed nature result in reduced maintenance needs, lower lifetime costs, and exceptional reliability even in high-cycle, continuous operation. The design allows for high-speed capability while maintaining stability and precision.

Typical applications for the THK LMIK Linear Bushing are found across a wide spectrum of industries where reliable linear guidance is paramount. In industrial automation and machinery, it is extensively used in the linear axes of pick-and-place units, automated assembly robots, material handling systems, and the sliding doors of industrial ovens or environmental chambers. Within the automotive manufacturing sector, these bushings are integral to precision fixturing and testing equipment, welding gun manipulators, and parts transfer mechanisms on production lines. For precision equipment, the LMIK model provides the critical guidance in optical positioning stages, measuring and inspection instruments, semiconductor manufacturing equipment, and medical device actuators, where its accuracy, smooth motion, and compact form factor are essential. Its versatility and robustness make it a fundamental component for engineers designing advanced mechanical systems requiring dependable, long-lasting linear motion.

The THK Guide Ball Bushing Linear Bushing flanged type Cut Flange Model LMH represents a specialized linear motion solution engineered for applications requiring compact design, high rigidity, and precise guidance. This flanged linear bushing features a unique cut-flange design that allows for simplified mounting and space-saving integration into machinery and equipment. The bushing incorporates a ball-recirculating mechanism, where precision-ground balls circulate smoothly between the shaft and bushing housing, providing low-friction linear motion with minimal resistance. Key technical features include a hardened steel construction for enhanced durability, a cut flange that facilitates easy installation and removal, and a compact cross-section optimized for confined spaces. The flanged design provides stable mounting surfaces, ensuring secure attachment to machine structures without additional brackets or complex fixtures.

Performance advantages of the Model LMH are significant across various operational parameters. It delivers exceptional load-carrying capacity, supporting both radial and moment loads with high rigidity, which minimizes deflection under stress. The low-friction coefficient of the ball-recirculating system results in smooth, consistent motion, reducing energy consumption and wear over time. This design also contributes to high positional accuracy and repeatability, critical for precision-driven applications. Maintenance requirements are minimal due to the bushing's self-lubricating options and sealed configurations that protect against contaminants like dust, chips, and moisture. Additionally, the cut-flange model allows for axial displacement adjustment, enabling fine-tuning of preload and alignment to optimize performance in dynamic conditions.

Typical applications span multiple industries, leveraging the bushing's reliability and efficiency. In industrial machinery, it is commonly used in automated assembly lines, CNC machine slides, and material handling systems where precise linear guidance is essential for throughput and quality. The automotive sector employs the Model LMH in robotic welding arms, engine component testers, and suspension alignment equipment, benefiting from its robustness and resistance to vibrational stresses. In precision equipment, it finds use in optical positioning stages, medical device actuators, and semiconductor manufacturing tools, where its compact design and high accuracy support micron-level tolerances. Overall, the THK LMH flanged type Cut Flange Linear Bushing offers a versatile, high-performance solution for engineers seeking to enhance motion control in demanding environments, combining ease of installation with long-term operational reliability.

The THK Guide Ball Bushing Linear Bushing, specifically the flanged type Cut Flange Model LMIH, represents a high-performance linear motion solution engineered for applications demanding compact design, high rigidity, and exceptional accuracy. This model features a unique flanged housing with a cut flange design, which facilitates simplified mounting and space savings in machinery layouts. The bushing incorporates a precision-engineered ball recirculation system, where high-grade steel balls cycle smoothly through load-bearing races and return guides, ensuring consistent, low-friction linear travel. Key technical attributes include its compact cross-sectional profile, high load capacity—supporting both radial and moment loads—and corrosion-resistant construction, often utilizing hardened steel or optional stainless-steel materials for enhanced durability in harsh environments.

Performance advantages of the LMIH Cut Flange model are substantial, beginning with its exceptional smoothness and positional accuracy, which minimize vibration and contribute to extended service life. The flanged design allows for direct mounting to machine surfaces, eliminating the need for additional support blocks and reducing assembly time and complexity. This design also enhances stability under heavy loads, making it ideal for applications subjected to dynamic forces. The low coefficient of friction inherent in the ball bushing system results in reduced energy consumption and heat generation, while the efficient sealing mechanisms protect internal components from contaminants like dust, chips, and moisture, ensuring reliable operation in demanding conditions. Maintenance requirements are minimal due to the long-lasting lubrication and robust construction, reducing downtime and total cost of ownership.

Typical applications for the THK LMIH Cut Flange Linear Bushing span a wide range of industries, leveraging its precision and reliability. In industrial machinery, it is commonly integrated into CNC machining centers, where it guides tool slides and feed mechanisms with high repeatability, ensuring precise cutting and milling operations. Within automotive manufacturing systems, this component is employed in assembly robots, transfer lines, and testing equipment, where it supports linear motion in pick-and-place units, welding arms, and inspection jigs, contributing to efficient production cycles and consistent quality control. In precision equipment, such as semiconductor manufacturing devices, medical imaging systems, and optical positioning stages, the LMIH model provides the smooth, backlash-free motion necessary for sub-micron accuracy and stability. Its compact flange design is particularly advantageous in space-constrained applications, such as compact automation modules or embedded sensor systems, where it delivers reliable performance without compromising on footprint or load-bearing capability.

THK's LMF Series Flanged Type Linear Bushings represent a high-performance circular flanged ball bushing solution designed for robust linear motion applications where space optimization and mounting convenience are critical. These precision components feature an integrated flange with mounting holes, allowing direct attachment to machine structures without additional brackets or complex fixtures. Constructed from high-carbon chromium bearing steel (SUJ2) with precision grinding and heat treatment, the LMF bushings provide exceptional hardness (HRC 58-64) and wear resistance. The flange design incorporates standardized hole patterns for secure fastening while maintaining concentricity with the shaft axis.

Technical features include the patented THK Gothic arch groove configuration, which ensures continuous point contact between balls and raceways to minimize friction and eliminate slipstick motion. The compact flange profile reduces overall envelope dimensions while providing generous load-bearing surface area. Precision honing of the inner diameter delivers consistent running accuracy, with standard clearance classifications (C0, C1) available to match application requirements. Optional seals and shields provide effective contamination protection in demanding environments, while lubrication grooves facilitate uniform grease distribution along the entire travel length.

Performance advantages stem from THK's ball recirculation technology, which maintains smooth motion characteristics even under high moment load conditions. The flanged configuration distributes forces evenly across the mounting surface, enhancing stability during acceleration and deceleration cycles. These bushings demonstrate high rigidity with minimal elastic deformation, maintaining positioning accuracy during repeated reciprocating motions. Their optimized ball complement and raceway geometry yield low noise operation while accommodating minor shaft misalignments through built-in compliance.

Typical applications span industrial automation where these components guide linear actuators in packaging machinery, material handling systems, and assembly robots. In automotive manufacturing, LMF bushings provide precise guidance for welding gun manipulators, brake line installation fixtures, and engine component transfer mechanisms. Precision equipment implementations include coordinate measuring machine probes, optical positioning stages, and semiconductor wafer handling equipment where the flange mounting simplifies integration into compact instrument designs. The series' versatility makes it suitable for both vertical and horizontal orientations across cleanroom, general industrial, and moderate contamination environments when paired with appropriate sealing options.

The THK LMIF series represents a flanged-type circular flange linear bushing engineered for robust performance in demanding linear motion applications. As part of THK's renowned Ball Bushing lineup, this component integrates precision-ground components with advanced bearing technology to deliver exceptional accuracy and longevity. Its construction features a high-carbon chromium bearing steel outer ring subjected to special heat treatment, creating a hardened raceway that resists deformation under heavy loads. The flange design incorporates four symmetrically positioned mounting holes with precise counterbores, enabling secure fixation to machine frames or moving elements using standard socket head cap screws.

Key technical specifications include standardized bore sizes ranging from 3mm to 50mm, with corresponding outer diameters and flange dimensions engineered for dimensional stability. The internal structure employs a patented retainer system that maintains precise ball spacing while preventing slippage during high-speed operation. Each bushing undergoes THK's proprietary grinding process to achieve raceway roundness within microns, ensuring smooth rolling motion without stick-slip phenomena. The LMIF model specifically addresses alignment challenges through its integrated flange, which provides enhanced mounting rigidity compared to standard linear bushings.

Performance advantages begin with the optimized ball circulation path that minimizes friction coefficients to as low as 0.001-0.004, significantly reducing energy consumption and heat generation. The hardened steel construction supports static load capacities up to 6.5kN and dynamic loads reaching 3.2kN for standard sizes, maintaining dimensional stability even under substantial radial forces. With noise levels below 65dB during operation and vibration damping characteristics superior to plain bearings, these bushings contribute to quieter machinery operation. The sealed variants incorporate non-contact labyrinth seals or contact-type rubber seals that effectively exclude contaminants while retaining lubrication, extending maintenance intervals to over 10,000 operating hours in typical industrial environments.

In industrial automation, LMIF bushings serve as critical components in CNC machine tool slides, where their high rigidity supports precise positioning during heavy cutting operations. Automotive manufacturing systems employ these bushings in welding robot transfer mechanisms, leveraging their impact resistance to withstand repeated acceleration cycles exceeding 2G. Semiconductor fabrication equipment utilizes the precision-grade versions for wafer handling robots, where sub-micron positioning repeatability is mandatory. Packaging machinery integrates these components in filling station actuators, benefiting from their corrosion-resistant options when handling food products or chemicals. Additional applications include precision measuring instrument stages, medical device assembly systems, and aerospace component testing equipment where reliable linear guidance is paramount. The flange configuration proves particularly valuable in space-constrained designs, eliminating the need for separate mounting blocks while providing superior moment load resistance compared to standard bushings.

THK's LMCK L SERIES Linear Bushing flanged type Square Flange Model represents a high-performance, compact linear motion solution engineered for precision, durability, and ease of integration in demanding industrial environments. This flanged-type ball bushing linear bushing features a square flange design that simplifies mounting and enhances structural rigidity, making it ideal for applications where space constraints and alignment accuracy are critical. Constructed from high-carbon chromium bearing steel, the LMCK L SERIES undergoes rigorous heat treatment processes to achieve superior surface hardness and core toughness, ensuring exceptional wear resistance and long service life even under high-load conditions. The precision-ground raceways and optimized ball circuit design minimize friction and provide smooth, low-noise operation, contributing to enhanced positioning accuracy and repeatability.

Key technical features include the incorporation of high-grade steel balls with controlled diameter variations, which distribute loads evenly and reduce vibration during operation. The bushing's compact cross-section maximizes load capacity while minimizing overall dimensions, allowing for more streamlined machine designs. A corrosion-resistant surface treatment, typically chrome plating or black oxide coating, protects against environmental factors such as moisture and chemical exposure. The square flange configuration offers multiple mounting hole patterns, facilitating secure attachment to machine bases, slides, or actuators without requiring additional adapters. Maintenance-friendly design elements, such as integrated grease grooves and optional seals, enable effective lubrication retention and contamination exclusion, reducing downtime and extending maintenance intervals.

Performance advantages of the LMCK L SERIES include its ability to handle combined loads—supporting radial, reverse radial, and moment loads simultaneously—thanks to its four-point contact structure. This capability ensures stable motion control and minimizes deflection under complex force conditions. The low coefficient of friction results in higher efficiency, reducing power consumption and heat generation in continuous operation. With precision grades available, these bushings achieve running accuracy within micrometers, making them suitable for applications demanding tight tolerances. Their high-speed compatibility, facilitated by optimized recirculation systems, allows for rapid reciprocating motions without sacrificing smoothness or generating excessive noise.

Typical applications span across industrial machinery, where LMCK L SERIES units are deployed in CNC machine tool slides, automated assembly robots, and precision measuring instruments. In automotive systems, they serve in welding equipment, engine component positioning devices, and brake system test rigs, where reliability and precision are paramount. Within precision equipment, these linear bushings are integral to semiconductor manufacturing tools, optical alignment stages, and medical device actuators, ensuring micron-level accuracy and contamination-free operation. Their robust construction and versatility also make them suitable for packaging machinery, material handling systems, and aerospace instrumentation, where consistent performance under varying temperatures and loads is essential. By combining advanced materials, precision engineering, and user-centric design, THK's LMCK L SERIES delivers a reliable linear motion foundation that enhances machine efficiency, reduces lifecycle costs, and supports innovation across diverse technological fields.

The THK LMCH L SERIES Cut Flange Model represents a specialized evolution in linear motion technology, designed as a flanged-type linear bushing that integrates the renowned Ball Bushing guide system for exceptional precision and durability. This model features a unique cut flange design, which allows for simplified mounting and space-saving integration into compact machinery layouts. Engineered with high-carbon chromium bearing steel rings and precision-ground balls, the LMCH L SERIES ensures smooth, low-friction linear motion under varying load conditions. Its construction includes a resin retainer that minimizes noise and vibration while maintaining optimal ball circulation, enhancing operational stability in high-speed applications. The flanged configuration provides robust support and easy fixation to machine structures, reducing the need for additional mounting components and streamlining assembly processes.

Key technical features of the LMCH L SERIES include its compact cross-sectional design, which maximizes load capacity without increasing overall dimensions. The bushing incorporates THK's advanced guide technology, offering high rigidity and resistance to moment loads, making it suitable for applications requiring precise alignment and minimal deflection. It supports high-speed operations with minimal heat generation, thanks to efficient lubrication pathways and optimized ball groove geometry. The cut flange allows for radial clearance adjustment, enabling fine-tuning of preload to match specific application demands, from light-duty positioning to heavy-load carrying tasks. Additionally, the model is available in various sizes and tolerances, ensuring compatibility with international standards and custom machinery requirements.

Performance advantages of this linear bushing are evident in its extended service life and reduced maintenance needs. The precision-ground components and superior material quality contribute to low wear rates, even in contaminated environments, while the sealed design options protect against dust and debris ingress. This results in consistent accuracy and repeatability, critical for automated systems. The LMCH L SERIES excels in high-acceleration scenarios, providing smooth motion with minimal stick-slip effect, which enhances positioning accuracy and reduces energy consumption. Its lightweight yet robust construction allows for faster cycle times and improved efficiency in dynamic applications.

Typical applications span industrial machinery, automotive systems, and precision equipment. In industrial automation, it is commonly used in CNC machine slides, robotic arms, and pick-and-place units, where reliable linear guidance is essential for repetitive tasks. Within the automotive sector, the LMCH L SERIES integrates into assembly line conveyors, engine testing fixtures, and brake system components, offering durability under high-vibration conditions. For precision equipment, such as medical devices, semiconductor manufacturing tools, and optical instruments, this bushing provides the stability and accuracy needed for micron-level movements. Its versatility also extends to packaging machinery, printing presses, and material handling systems, where space constraints and performance reliability are paramount. By delivering a balance of compact design, high load capacity, and precision, the THK LMCH L SERIES Cut Flange Model supports innovation across diverse industries, enabling smoother operations and enhanced productivity.

The THK LMCF L SERIES Linear Bushing, specifically the flanged type Circular Flange Model, represents a high-performance linear motion solution engineered for precision, durability, and ease of integration in demanding applications. This compact, flanged linear bushing is designed to facilitate smooth and accurate linear guidance along a shaft, utilizing a ball-bushing mechanism that minimizes friction and ensures reliable operation under various load conditions. Its circular flange design allows for straightforward mounting and secure fixation, making it an ideal choice for applications where space constraints and precise alignment are critical.

Key technical features of the LMCF L SERIES include its advanced ball retainer system, which prevents ball-to-ball contact and reduces noise and vibration during operation. The bushing is constructed from high-carbon chromium bearing steel, providing exceptional hardness and wear resistance, while the option for stainless steel components makes it suitable for corrosive environments. It incorporates a unique seal design that effectively excludes contaminants like dust, chips, and moisture, extending service life and reducing maintenance requirements. The flanged configuration enhances stability by distributing loads evenly and simplifying installation in compact assemblies, with standardized dimensions ensuring compatibility across a wide range of industrial setups.

Performance advantages of this linear bushing are evident in its high load capacity, both radial and moment loads, enabling it to handle substantial forces without compromising accuracy. The low coefficient of friction, achieved through precision-ground balls and optimized raceway geometry, results in smooth, consistent motion with minimal stick-slip, contributing to improved positioning repeatability and energy efficiency. Its long service life, even under high-speed or frequent reciprocating conditions, reduces downtime and total cost of ownership. Additionally, the LMCF L SERIES offers excellent resistance to shock and vibration, making it a dependable component in dynamic applications.

Typical applications span multiple industries, including industrial machinery, where it is commonly used in automated assembly lines, packaging equipment, and CNC machine tool slides to ensure precise linear movement. In automotive systems, it finds use in throttle controls, seat adjustment mechanisms, and transmission components, where reliability and compact design are paramount. For precision equipment, such as medical devices, semiconductor manufacturing tools, and optical instruments, the LMCF L SERIES provides the accuracy and smoothness required for sensitive operations. Its versatility also extends to robotics, material handling systems, and general automation, where it enhances performance in linear guides, actuators, and positioning stages. Overall, the THK LMCF L SERIES Linear Bushing delivers a robust, efficient solution for applications demanding high precision and durability in linear motion systems.