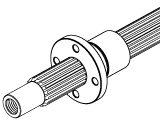

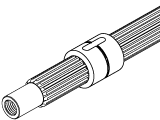

THK's Spline Nut Model DP, DPM, and DPM SERIES represent a sophisticated class of linear motion components engineered for applications demanding high torque transmission, exceptional rotational accuracy, and robust load-bearing capabilities. These spline nuts function as the critical interface between a rotating spline shaft and a moving carriage or table, facilitating precise linear guidance while simultaneously handling significant torsional forces. The fundamental design incorporates a nut body with an internal spline profile that meshes perfectly with the external teeth of a spline shaft. This configuration allows for the simultaneous transfer of rotary motion and linear travel, making it an ideal solution for complex motion control scenarios where space is at a premium and multiple degrees of freedom are required.

The technical features of these series are meticulously crafted for superior performance. The nuts utilize THK's advanced manufacturing techniques to ensure high-precision spline grooves, resulting in minimal backlash and smooth, consistent operation. Many models within these series incorporate a unique ball circulation system. This system features precision-ground grooves in both the nut and the shaft, with recirculating balls providing the rolling contact. This design drastically reduces friction compared to traditional sliding spline contacts, leading to higher efficiency, lower heat generation, and significantly extended service life. The construction often employs high-carbon chromium bearing steel, which is through-hardened to provide exceptional wear resistance and durability under heavy loads and high-speed operation. Sealing units are integrated to effectively shield the internal ball circuits and spline grooves from contaminants like dust and chips, while also retaining lubrication for maintenance-free intervals.

The performance advantages of the DP, DPM, and DPM SERIES are substantial. The rolling contact design enables high-speed rotation and linear movement with remarkable smoothness and positional accuracy. The ability to handle combined loads—including radial, axial, and moment loads—simplifies machine design by reducing the number of components needed. Their compact and rigid structure contributes to a smaller machine footprint and enhances the overall stiffness of the system, which is crucial for maintaining precision under dynamic forces. The low-friction operation translates directly into higher mechanical efficiency, requiring smaller drive motors and reducing energy consumption.

These spline nuts find extensive application across a wide spectrum of high-demand industries. In industrial machinery, they are indispensable in the rotary tables of machining centers, enabling precise indexing and heavy-duty milling operations. They are central to the automation of pallet changers and tool changers, where reliable positioning and torque transmission are paramount. Within the automotive manufacturing sector, they are deployed in high-precision welding robots, ensuring accurate and repeatable movement of heavy welding guns, and in high-speed transfer lines for moving engine blocks and other components. In the realm of precision equipment, these components are critical for the smooth and accurate rotational axes of semiconductor wafer handling robots, inspection systems, and advanced optical alignment devices, where any backlash or vibration would compromise the entire process. The THK Spline Nut series thus provides a foundational technology for creating more efficient, compact, and highly reliable automated systems.

THK's Spline Nut Model DP, DPM, and DP SERIES represent a specialized class of linear motion components engineered for applications demanding high torque transmission, exceptional rotational accuracy, and robust load-bearing capabilities. These spline nuts are integral to systems where a shaft must simultaneously support significant moment loads while providing precise rotational movement. The design fundamentally consists of a nut that engages with a spline shaft, featuring precisely machined grooves that interlock to transmit torque efficiently and maintain strict angular alignment.

The technical features of this series are defined by its high rigidity and precision. The nuts are manufactured with a unique ball-spline structure, where recirculating balls circulate between the grooves of the nut and the spline shaft. This design achieves a highly efficient rolling contact, drastically reducing friction compared to traditional sliding spline interfaces. The DP SERIES, for instance, is characterized by its compact and lightweight design, offering a high degree of freedom in machinery layout. The components are typically constructed from high-carbon chromium bearing steel, heat-treated to ensure superior surface hardness and core toughness for long-term durability and resistance to wear and shock loads. Sealing units are often integrated to protect the critical ball grooves from contaminants like dust and chips, ensuring consistent performance in harsh environments.

The performance advantages are substantial, primarily revolving around high rotational accuracy and the capacity to handle complex loads. The rolling ball contact ensures smooth, low-friction rotation with minimal backlash, enabling precise positional control and repeatability. This design allows the spline nut to support high moment loads—including tilting and torque moments—while simultaneously accommodating linear motion along the shaft. This combination of high torque capacity and moment load resistance eliminates the need for additional support mechanisms, simplifying overall system design and reducing both footprint and component count. The result is a solution that offers high efficiency, exceptional stiffness for improved machining or positioning accuracy, and remarkable longevity with minimal maintenance requirements.

Typical applications for the THK DP, DPM, and DP SERIES spline nuts are found in advanced industrial machinery, automotive manufacturing, and precision equipment where multi-axis control is paramount. In industrial automation, they are critical in the rotary axis of industrial robots, CNC rotary tables, index tables, and automatic tool changers, where they provide the precise and powerful rotation needed for complex manipulations. Within automotive production lines, these components are employed in welding robot arms, material handling systems, and precision assembly jigs. In the realm of precision equipment, they facilitate accurate angular positioning in optical instrument stages, semiconductor manufacturing equipment, and various measuring devices, ensuring the high degree of accuracy and reliability essential for modern, high-performance automated systems.