THK LM Guide represents a comprehensive series of linear motion systems engineered to deliver exceptional precision, rigidity, and longevity in demanding industrial applications. These systems consist of a rail and a block equipped with recirculating balls or rollers, facilitating smooth, low-friction linear movement along a fixed axis. A defining technical feature is the incorporation of THK's patented Caged Ball

THK Ball Spline represents a sophisticated advancement in linear motion technology, engineered to simultaneously transmit torque and facilitate precise linear movement with exceptional rigidity and minimal backlash. This unique component integrates a spline shaft with precision-ground ball grooves and a spline nut containing recirculating ball bearings, creating a highly efficient mechanism for applications demanding both rotational force and linear guidance. The design ensures smooth, accurate motion while handling significant torsional loads, making it indispensable in scenarios where conventional linear guides or ball screws would fall short.

Key technical features distinguish the THK Ball Spline in demanding environments. Its compact, integral construction eliminates the need for separate torque transmission and linear guidance systems, reducing overall system complexity and space requirements. The ball grooves on the spline shaft are precision-machined to maintain consistent contact with the bearing balls, ensuring uniform load distribution and enhanced durability. Advanced sealing technologies protect against contaminants like dust and moisture, while specialized lubrication systems extend service life even in high-cycle operations. Options include standard, flange, and cylindrical nut configurations to accommodate diverse mounting requirements, alongside variations in preload levels to optimize stiffness and precision for specific operational needs.

Performance advantages of the THK Ball Spline translate directly into operational reliability and efficiency. Its high torsional rigidity allows for precise positioning under heavy loads, with minimal angular deflection ensuring repeatable accuracy in automated processes. The low-friction ball recirculation mechanism contributes to smooth motion, reducing vibration and noise while enabling high-speed operation without sacrificing precision. Backlash is virtually eliminated through precision manufacturing and adjustable preload, critical for applications requiring exact synchronization between rotary and linear axes. These characteristics result in reduced maintenance intervals, lower energy consumption due to efficient power transmission, and extended component lifespan even in continuous or high-duty cycles.

Typical applications span industries where precision, reliability, and compact design are paramount. In industrial machinery, THK Ball Splines are integral to robotic arms, automated assembly systems, and CNC machine tool changers, where they provide simultaneous rotary and linear motion for tool positioning and workpiece handling. The automotive sector utilizes them in welding robots, precision testing equipment, and transmission assembly lines, benefiting from their ability to withstand harsh environments while maintaining accuracy. Within precision equipment, they enable critical functions in semiconductor manufacturing devices, optical alignment systems, and medical imaging apparatus, where smooth, backlash-free motion is essential for micron-level precision. By delivering robust performance in these diverse settings, THK Ball Spline components support enhanced productivity, reduced downtime, and superior end-product quality across modern manufacturing and automation landscapes.

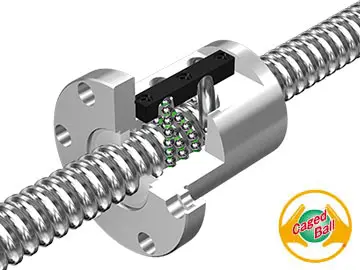

THK Ball Screws represent the pinnacle of precision linear motion technology, engineered to convert rotational motion into smooth, highly accurate linear movement with exceptional efficiency. These components feature precisely ground screw shafts with helical raceways and matching nuts containing recirculating ball bearings that roll along these tracks. This fundamental design eliminates sliding friction, achieving mechanical efficiencies exceeding 90% – a dramatic improvement over traditional Acme screws. The ball screw's construction includes a screw shaft, nut, ball bearings, and a ball return system that continuously circulates the balls through the load-bearing zone, creating a perpetually rolling motion.

Several technical features distinguish THK Ball Screws in demanding applications. Their precision grinding technology ensures lead accuracy grades from standard (C7) to ultra-precise (C0), with the highest grade achieving positional accuracy within 5 micrometers per 300mm of travel. Advanced preloading methods – including double-nut and offset preload designs – eliminate axial play while maintaining smooth operation under varying load conditions. THK's proprietary ball circulation systems, such as the deflector and endcap return mechanisms, provide optimized ball flow paths that minimize vibration and noise even at high speeds. Specialized sealing technologies integrate multiple labyrinth seals and wipers to exclude contaminants while retaining lubrication, significantly extending service intervals in harsh environments. The components are available in various configurations including precision ground screws for highest accuracy, rolled screws for cost-effective solutions, and miniature versions for compact applications.

The performance advantages of these ball screws translate directly into operational benefits across industries. Their high efficiency reduces required motor torque, allowing smaller drive components and lower energy consumption. The minimal backlash and high rigidity enable exceptional positional repeatability, critical for precision manufacturing processes. With dynamic load ratings exceeding 30,000 hours in many configurations, THK Ball Screws deliver remarkable longevity that reduces maintenance frequency and total cost of ownership. Their ability to operate at temperatures from -20°C to 80°C without performance degradation ensures reliability across diverse operating conditions. The low noise generation, often below 65 dB even at rapid traverse rates, contributes to improved workplace environments.

In industrial machinery applications, THK Ball Screws serve as the driving force behind CNC machining centers, injection molding machines, and precision presses where they provide the accurate table positioning and high thrust capabilities essential for manufacturing tolerance-critical components. The automotive industry employs these ball screws in electric power steering systems, transmission assembly equipment, and brake line manufacturing machinery where reliability and precision directly impact vehicle safety and performance. Throughout precision equipment sectors, they enable the exacting motion requirements of semiconductor manufacturing apparatus, medical diagnostic devices, and coordinate measuring machines – applications where sub-micron positioning accuracy is non-negotiable. From high-speed packaging lines to aerospace component fabrication, THK Ball Screws deliver the precise, reliable linear motion that modern industrial systems demand.

THK Cross Roller Bearings represent a pinnacle of precision engineering in linear motion technology, designed to handle complex load scenarios with exceptional rigidity and accuracy. These bearings feature a unique cylindrical roller arrangement where adjacent rollers are oriented at right angles to each other in a single compact unit. This cross-roller configuration enables the bearing to simultaneously support radial, axial, and moment loads without requiring multiple bearing assemblies. The rollers make line contact with the raceways, distributing stress evenly across the bearing surfaces while maintaining minimal elastic deformation under load. Manufactured from high-grade chromium steel and subjected to THK's proprietary heat treatment processes, these components achieve superior hardness and wear resistance. The inclusion of precision-ground spacers between rollers ensures consistent roller spacing and prevents sliding friction, while integrated sealing mechanisms protect against contamination in harsh operating environments.

The performance advantages of THK Cross Roller Bearings stem directly from their innovative design characteristics. Their compact cross-roller arrangement delivers significantly higher rigidity compared to conventional ball bearings, with rotational accuracy typically within 1 to 5 microns depending on the precision grade. This enhanced rigidity minimizes deflection under load, making them ideal for applications requiring precise positioning and repeatability. The optimized contact geometry between rollers and raceways results in smooth motion characteristics with minimal friction variation throughout the rotation cycle. These bearings exhibit exceptionally low starting and running torque while maintaining consistent rotational performance across varying speed ranges. Their space-saving design consolidates multiple bearing functions into a single compact unit, reducing overall system complexity and installation requirements. The high load capacity-to-size ratio allows for more streamlined machine designs without compromising performance, while the reduced number of components decreases potential failure points and simplifies maintenance protocols.

In industrial automation, THK Cross Roller Bearings serve as critical components in robotic arm joints, rotary tables, and indexing mechanisms where precise angular positioning is paramount. Their ability to handle combined loads makes them indispensable in machine tool applications, particularly in rotary pallet changers, tilting spindles, and rotary grinding attachments. The automotive manufacturing sector utilizes these bearings in welding robot positioning units, automated assembly fixtures, and precision testing equipment requiring high moment load capacity. Within semiconductor and electronics production, they enable the precise motion control essential for wafer handling robots, wire bonding machines, and inspection system stages. Medical equipment manufacturers incorporate these bearings into CT scanner gantries, surgical robot articulation points, and laboratory automation systems where smooth, accurate rotation is critical. Optical instrument manufacturers rely on them for precision rotary stages in measuring devices, telescope positioning systems, and laser processing equipment, leveraging their minimal rotational error and vibration damping characteristics to achieve sub-micron level accuracy in demanding applications.

THK Link Ball represents a sophisticated evolution in linear motion technology, combining robust construction with precision engineering to deliver exceptional performance in demanding applications. This system features a unique linkage mechanism where high-precision steel balls circulate smoothly within a specially designed track, creating a highly efficient motion transfer system with minimal friction and wear. The Link Ball’s compact yet durable design incorporates hardened steel components and advanced sealing technologies to protect against contaminants, ensuring long-term reliability even in harsh operating environments. Its modular architecture allows for flexible configurations, supporting both guided linear motion and complex multi-axis assemblies with minimal maintenance requirements.

Key technical features include optimized ball groove geometry that maximizes contact area while distributing loads evenly across the bearing surfaces. This design significantly reduces stress concentrations, leading to extended service life and consistent accuracy. The incorporation of THK’s proprietary C-Lube lubricating system provides continuous, maintenance-free lubrication for up to 20,000 kilometers of travel, eliminating downtime for re-lubrication in hard-to-reach installations. With precision grades achieving positional accuracy within microns and rigidity ratings exceeding conventional ball bushings by 40%, the Link Ball system maintains stable performance under high moment loads and vibration conditions. Its corrosion-resistant options, including stainless steel variants and specialized coatings, make it suitable for cleanrooms, food processing, and chemically aggressive settings.

Performance advantages are demonstrated through its ability to operate at speeds up to 5 m/s while maintaining low noise levels below 65 dB, critical for precision manufacturing and laboratory equipment. The low friction coefficient (as low as 0.001) enables energy savings up to 30% compared to traditional slide systems, with heat generation minimized even during rapid reciprocating cycles. Its high stiffness-to-weight ratio allows for faster acceleration in automation systems while reducing structural support requirements. The self-aligning capability compensates for mounting inaccuracies, simplifying installation and preventing edge loading that could compromise accuracy. These characteristics result in reduced total cost of ownership through decreased energy consumption, minimal maintenance interventions, and extended replacement intervals.

In industrial machinery, THK Link Ball systems are deployed in CNC machining centers for tool changer mechanisms, where high-speed positioning and shock resistance are critical. Automotive manufacturing utilizes them in robotic welding arms and assembly line transfer systems, benefiting from their contamination resistance and durability in high-particulate environments. Precision equipment applications include semiconductor wafer handling robots, where micron-level accuracy and cleanroom compatibility prevent product contamination. Medical device manufacturers incorporate these components into MRI positioning systems and surgical robot arms, leveraging their smooth motion and magnetic field compatibility. Additional implementations range from packaging machinery with rapid cycling requirements to aerospace testing equipment demanding vibration damping characteristics, proving the technology’s versatility across virtually every sector of advanced manufacturing.

THK Rod Ends represent a specialized category of spherical plain bearings engineered to accommodate angular misalignment and oscillating movements within mechanical assemblies. These components consist of a high-precision, hardened steel ball stud housed within a spherical inner ring, which is itself encased in a robust outer ring. The entire assembly is designed to facilitate smooth, low-friction rotational and swiveling motion across multiple axes, making them indispensable for linking mechanical elements in systems where alignment is not perfectly static. A critical technical feature is the incorporation of THK's advanced lubrication technology; many models are pre-lubricated and feature integrated seals or shields that effectively retain grease and exclude contaminants like dust, moisture, and metal chips. This significantly extends service life and reduces maintenance requirements. The materials used are typically high-carbon chromium bearing steel for the ball stud and rings, often with surface treatments or alternative materials like stainless steel available for enhanced corrosion resistance in harsh environments.

The performance advantages of THK Rod Ends are substantial, primarily revolving around reliability, precision, and durability. Their low starting and running torque ensures responsive and efficient power transmission in linkage mechanisms. The high static and dynamic load capacities allow them to withstand significant forces, including shock loads, without compromising the integrity of the movement. This robust construction minimizes backlash and wear, leading to consistent positional accuracy over extended periods. By effectively managing misalignment, they prevent binding and reduce stress concentrations on connected parts, which in turn lowers noise and vibration, contributing to smoother overall system operation and prolonged lifespan for the entire machinery.

In industrial machinery, THK Rod Ends are ubiquitous in applications requiring precise articulation. They are fundamental components in the linkage systems of industrial robots, where they connect actuators to arms and grippers, enabling complex, multi-axis movements with high repeatability. They are also found in the control rods of packaging machinery, conveyor system guides, and the adjustable linkages within printing and textile equipment. Within the automotive sector, these rod ends are critical for safety and performance. They are employed in steering tie-rod ends, throttle linkage connections, and suspension components like stabilizer bar links, where they must reliably transmit steering inputs and absorb road-induced vibrations. For precision equipment, such as optical positioning stages, semiconductor manufacturing tools, and medical diagnostic devices, the high precision and minimal play of THK Rod Ends are essential. They ensure that fine adjustments in linkages translate into accurate, repeatable movements, which is paramount for the functionality and accuracy of such sensitive instruments.

THK Spherical Plain Bearing represents a pivotal advancement in articulating joint technology, engineered to accommodate angular misalignment and oscillating movements with exceptional reliability. These self-lubricating or maintenance-free bearings feature a spherical inner ring and outer ring, with a sliding contact surface that enables smooth rotational and tilting motions even under high loads and slow speeds. The bearing's construction incorporates a hardened steel inner ring and outer ring, paired with a specialized sliding material—often a PTFE-based liner or phosphor bronze bushing—that ensures low friction, minimal wear, and long service life without frequent re-lubrication. Available in various configurations, including rod ends and pillow blocks, THK's spherical plain bearings are sealed to prevent contamination from dust, moisture, or debris, making them ideal for harsh operating environments.

Key technical features include high load capacity in radial, axial, and moment directions, thanks to the optimized spherical geometry and material selection. The bearings support static loads up to several hundred kilonewtons and dynamic loads suited for continuous operation, with temperature resistance ranging from -30°C to +80°C for standard models, and up to +120°C for high-temperature variants. Their low coefficient of friction, typically between 0.05 and 0.20 depending on the liner material, allows for precise movement control and reduces energy consumption. Performance advantages are evident in their ability to damp vibrations, absorb shocks, and compensate for mounting inaccuracies without sacrificing precision. This results in enhanced system stability, reduced maintenance intervals, and extended component lifespan, ultimately lowering total cost of ownership.

In industrial machinery, THK Spherical Plain Bearings are widely deployed in hydraulic cylinders, construction equipment linkages, and material handling systems, where they facilitate smooth articulation in excavator arms, conveyor pivots, and robotic joints. The automotive sector relies on them for suspension components, steering linkages, and transmission mounts, where their durability and tolerance to misalignment improve vehicle safety and ride comfort. For precision equipment, such as semiconductor manufacturing tools, optical alignment devices, and medical imaging systems, these bearings provide the exacting motion control necessary for repeatable positioning and vibration isolation. By integrating THK Spherical Plain Bearings, engineers achieve robust, maintenance-efficient designs that excel in demanding applications across diverse industries.

THK LM Stroke linear motion systems represent a comprehensive range of precision-engineered components designed to deliver controlled, guided linear movement in demanding industrial applications. The core of this system is the LM Stroke actuator, a pre-assembled, ready-to-install unit that integrates a high-rigidity ball screw or precision lead screw with a robust LM Guide block and shaft. This unified design eliminates the need for complex alignment and assembly on the user's end, ensuring optimal performance from the moment of installation. The system is engineered for exceptional stroke accuracy, providing reliable and repeatable linear positioning over its entire travel length.

Key technical features define the performance superiority of these systems. The incorporation of THK's renowned LM Guide technology ensures high load capacity, encompassing radial, reverse-radial, and moment loads, which allows for stable operation even under complex force conditions. The use of precision-ground ball screws with high efficiency minimizes torque requirements and reduces heat generation, contributing to higher operational speeds and a longer service life. For applications requiring quieter operation or resistance to corrosion, options with resin nuts or stainless-steel components are available. The actuators are often sealed with advanced wiper and scraper systems to effectively exclude contaminants like dust and chips, making them exceptionally durable in harsh environments.

The performance advantages translate directly into tangible benefits for machinery designers and operators. The high rigidity and accuracy of the LM Stroke system guarantee precise stop positions and smooth motion profiles, which are critical for maintaining product quality in automated processes. Its compact, space-saving design simplifies machine construction and reduces the overall footprint of the equipment. Furthermore, the pre-assembled nature of the unit drastically reduces assembly time and costs, while also minimizing the risk of installation errors that could compromise performance or longevity.

These characteristics make THK LM Stroke systems indispensable across a wide spectrum of modern industry. In industrial automation, they are the driving force behind the precise positioning of tools in CNC machining centers, the rapid and accurate component placement in assembly robots, and the reliable material handling in automated transfer lines. Within the automotive manufacturing sector, these actuators provide the critical linear motion for high-speed, high-precision tasks such as laser welding, precision press fitting, and automated quality inspection stations. In the realm of precision equipment, THK LM Stroke systems enable the ultra-fine movements required in semiconductor manufacturing apparatus, medical diagnostic devices like CT and MRI scanners, and advanced optical measuring instruments, where micron-level accuracy and unwavering reliability are non-negotiable.

THK LM Roller linear motion systems represent a significant advancement in roller-based guide technology, engineered to deliver exceptional precision, rigidity, and longevity in demanding industrial applications. At the core of these systems are uniquely designed cylindrical rollers arranged in a precise configuration within the guide blocks, which interact with specially profiled raceway tracks on the guide rails. This roller-based architecture allows for high load capacity—supporting substantial moment loads and complex force distributions—while maintaining smooth, low-friction motion. The rollers are manufactured to ultra-precise tolerances, ensuring consistent contact and minimal vibration, which is critical for applications requiring high positional accuracy and repeatability.

Key technical features include the incorporation of THK’s proprietary crowning and logarithmic profile on roller surfaces, which optimizes stress distribution and mitigates edge-loading effects, significantly extending service life even under high preload conditions. The systems are available in various preload grades and accuracy classes, allowing for customization based on specific stiffness and precision requirements. Sealing technologies integrated into the LM Roller units provide robust protection against contaminants such as dust, chips, and moisture, making them suitable for harsh environments without compromising performance. Additionally, these components are designed for ease of installation and maintenance, with options for lubrication systems that ensure consistent film formation on rolling surfaces, reducing wear and maintenance intervals.

Performance advantages of THK LM Roller systems are evident in their ability to operate at high speeds with minimal noise and heat generation, contributing to energy efficiency and operational stability. Their high rigidity minimizes elastic deformation under load, which is vital for maintaining accuracy in precision machining and automation tasks. The roller design also provides superior impact resistance compared to ball-based systems, making them ideal for applications involving sudden load changes or heavy shock loads. With low friction characteristics, these systems enable smoother accelerations and decelerations, reducing settling times and improving throughput in high-cycle operations.

Typical applications span a wide range of industries, including industrial machinery where LM Roller guides are employed in machining centers, CNC milling machines, and grinding equipment to ensure precise table movements and tool positioning. In automotive manufacturing, they are integral to robotic welding arms, transfer lines, and assembly systems that demand high load capacity and durability under continuous operation. Precision equipment sectors, such as semiconductor manufacturing, optical alignment systems, and medical device automation, leverage the high accuracy and smooth motion of THK LM Roller systems to achieve micron-level positioning and reliability. Their robustness also makes them suitable for heavy-duty applications in material handling, packaging machinery, and inspection systems, where long-term performance with minimal maintenance is essential.

THK Linear Ball Slides represent a fundamental advancement in precision linear motion technology, engineered to deliver exceptional accuracy, rigidity, and smooth movement in a compact, highly efficient package. These systems are built around a recirculating ball bearing mechanism that travels along a precision-ground slide rail, minimizing friction and enabling high-speed operation with remarkable positional repeatability. The core of the design features a rigid aluminum or steel slider block housing multiple rows of precision balls that circulate endlessly through a load-bearing raceway and return guides. This recirculation ensures consistent, low-friction motion, even under substantial loads, while the incorporation of high-grade seals and wipers protects the internal components from contaminants like dust, chips, and moisture, significantly enhancing operational life and reliability in harsh environments.

Key technical features include the ability to support loads in multiple directions—radial, reverse-radial, and lateral—due to the optimized groove geometry in both the rail and the slider. Many models offer pre-load adjustments, which eliminate internal clearance and increase rigidity, critical for applications requiring high precision and resistance to vibration or impact forces. The compact, low-profile design of many Linear Ball Slides allows for space-saving integration into machinery where envelope constraints are a primary concern. Performance advantages are substantial: these systems exhibit very low coefficients of friction, leading to reduced power consumption and heat generation. They maintain high positional accuracy over millions of cycles, with minimal maintenance requirements beyond periodic re-lubrication. The high rigidity and damping characteristics contribute to improved machining or assembly quality by minimizing deflection and vibration during operation.

Typical applications for THK Linear Ball Slides are widespread across industries demanding reliable and precise linear guidance. In industrial machinery, they are indispensable in CNC machining centers for tool changer arms, in automated assembly lines for positioning pallets and fixtures, and in precision measuring instruments for moving probes and sensors. The automotive industry utilizes them extensively in robotic welding and painting arms, automated test equipment for components, and high-speed pick-and-place systems for electronic control unit assembly. Within the realm of precision equipment, these slides are found in semiconductor manufacturing apparatus for wafer handling and lithography stages, medical devices such as DNA sequencers and automated analysis systems, and optical positioning systems where smooth, jitter-free movement is paramount. Their versatility, durability, and precision make THK Linear Ball Slides a cornerstone component for engineers designing next-generation automated systems where motion control is critical to performance and productivity.

THK Cross Roller Tables represent a pinnacle of precision linear motion technology, engineered to deliver exceptional rigidity, accuracy, and smooth operation in demanding industrial applications. These compact, high-performance tables incorporate a unique crossed roller bearing configuration, where cylindrical rollers are arranged perpendicularly between V-shaped guideways on both the base and moving table. This cross-roller design enables the table to support multi-directional loads—including radial, reverse radial, and moment loads—simultaneously with minimal deformation. The rollers undergo precision grinding and are spacered to prevent skewing and ensure consistent contact, resulting in remarkably smooth, low-friction motion and high positional repeatability.

Key technical features include the use of high-carbon chromium bearing steel for rollers and raceways, heat-treated to achieve superior hardness and wear resistance. The compact, integrated structure minimizes the overall height and footprint, making these tables ideal for space-constrained applications. Optional components such as precision ground lead screws, servo motor mounts, and limit switches can be integrated to create a complete linear motion system. Sealing mechanisms are often incorporated to protect the rolling elements from contaminants, enhancing longevity in harsh environments. The tables are available in various sizes and accuracy grades, with travel lengths tailored to specific operational needs.

Performance advantages of THK Cross Roller Tables are substantial. Their high rigidity allows for significant load capacity without sacrificing precision, making them suitable for applications requiring heavy-duty performance and fine positioning. The low friction coefficient ensures smooth, stick-slip-free motion even at low speeds, which is critical for precision machining and measurement tasks. With positioning accuracy down to micrometer levels and high repeatability, these tables maintain consistent performance over long operational lifetimes. Their efficient design also contributes to reduced power consumption and minimal maintenance requirements.

Typical applications span across industries where precision and reliability are paramount. In industrial machinery, they are employed in CNC machining centers for tool positioning, semiconductor manufacturing equipment for wafer handling, and assembly robots for precise component placement. Within automotive systems, these tables facilitate precise operations in engine machining lines, brake system testing equipment, and automated welding systems. In precision equipment, they are integral to optical instrument stages, coordinate measuring machines (CMMs), and medical device manufacturing systems where exact linear movement is critical. The versatility and robustness of THK Cross Roller Tables make them a preferred choice for engineers seeking to enhance the accuracy and efficiency of automated systems.

THK Flat Roller linear motion systems represent a significant advancement in roller-based guide technology, engineered to deliver exceptional rigidity, high load capacity, and smooth, precise movement under demanding industrial conditions. Unlike traditional ball-based systems, the Flat Roller design utilizes cylindrical rollers arranged in a flat, raceway configuration. This fundamental design choice eliminates the inherent stress concentrations found at the point contacts of balls, distributing loads over a broader surface area. The result is a guide mechanism capable of withstanding immense moment loads and forces from multiple directions without sacrificing operational smoothness or positional accuracy.

The technical features of the THK Flat Roller system are defined by its robust construction and intelligent roller management. The core component is the LM guide, which incorporates a rigid, precision-machined rail and a block containing the roller recirculation system. The rollers themselves are manufactured to exceptionally tight tolerances, ensuring consistent size and geometry for uniform load distribution and minimal vibration. A critical feature is the patented roller retainer, which prevents skewing and ensures the rollers maintain correct orientation throughout the recirculation path. This not only guarantees quiet, stable operation at high speeds but also significantly extends the system's service life by eliminating metal-to-metal contact and resultant wear between adjacent rollers.

Performance advantages are immediately evident in applications requiring supreme stiffness and heavy-load support. The large contact area between the rollers and the raceway grants the system a static load capacity several times greater than comparable ball-type guides of the same size. This inherent rigidity minimizes elastic deformation under load, leading to dramatically improved positioning accuracy and repeatability, even when subjected to heavy cutting forces or shock loads. Furthermore, the optimized sealing systems effectively shield the precision rolling elements from contaminants like dust, chips, and moisture, ensuring reliable performance and long-term accuracy in harsh environments such as machine shops or automated foundries.

Typical applications for THK Flat Roller systems are found wherever high precision and brute strength are non-negotiable. In industrial machinery, they are the backbone of heavy-duty machining centers, providing the stable platform for high-precision milling, drilling, and grinding operations. They are integral to the gantry systems of large-format CNC routers and laser cutters, where resistance to deflection over long spans is critical. Within the automotive industry, these components are deployed in high-throughput robotic welding and assembly lines, where they endure constant, high-moment loads with unwavering reliability. In the realm of precision equipment, THK Flat Roller guides are essential in semiconductor manufacturing apparatus, inspection machines, and precision measuring instruments, where their minimal friction, high rigidity, and smooth motion are paramount for achieving micron-level accuracy.

THK Roller Followers are precision-engineered linear motion components designed to provide smooth, reliable guidance and support in a wide range of industrial applications. These units consist of a stud-type or yoke-type shaft equipped with a high-precision needle roller bearing, allowing them to handle significant radial loads while maintaining minimal friction. The outer ring, often crowned to prevent edge loading, rotates smoothly on the bearing assembly, enabling consistent performance even under misalignment or high-stress conditions. Available in various configurations—including standard, eccentric, and heavy-duty types—THK Roller Followers are built to withstand harsh environments, with options for sealed designs that protect against contaminants like dust, chips, and moisture.

Key technical features distinguish THK Roller Followers in demanding settings. The incorporation of needle rollers within the bearing assembly ensures a high load-carrying capacity relative to their compact size, making them ideal for space-constrained applications. The outer ring is typically hardened and ground to enhance durability and wear resistance, while the crowned profile distributes loads evenly, reducing stress concentrations and extending service life. Sealing options, such as rubber or metal seals, provide effective protection against debris and fluid ingress, ensuring reliable operation in dirty or wet conditions. Additionally, the stud or yoke mounting designs simplify installation and allow for easy integration into existing machinery, with eccentric variants offering adjustable preload for precise alignment.

Performance advantages of THK Roller Followers include their ability to operate at high speeds with minimal noise and vibration, contributing to smoother machinery function and reduced maintenance needs. Their low-friction design minimizes heat generation, which is critical in continuous-operation systems, and the robust construction ensures stability under heavy loads and shock conditions. These attributes lead to improved accuracy and repeatability in motion control tasks, enhancing overall system efficiency. The longevity of these components reduces downtime and replacement costs, providing a cost-effective solution for high-cycle applications.

Typical applications span multiple industries, leveraging the versatility and reliability of THK Roller Followers. In industrial machinery, they are commonly used in cam followers, linear guides, and conveyor systems, where they guide moving parts and support loads in automation equipment, packaging machines, and material handling systems. Within automotive systems, these components find roles in assembly line robots, transfer mechanisms, and engine valve trains, where precision and durability are paramount. In precision equipment, such as semiconductor manufacturing devices, printing presses, and medical instrumentation, THK Roller Followers ensure accurate, repeatable motion in sensitive processes. Their adaptability to various environments and load requirements makes them a preferred choice for engineers seeking dependable linear motion solutions.

THK Cam Followers represent a specialized category of linear motion components engineered to provide exceptionally smooth and reliable motion transfer in cam-driven mechanisms and guide applications. These precision devices consist of a stud-type or yoke-type shaft with a high-capacity, needle roller bearing unit integrated at one end. The outer ring, or outer race, is designed with a thick outer wall and is often through-hardened to withstand high loads and resist brinelling, ensuring long-term dimensional stability and operational integrity under demanding conditions. A critical technical feature is the crowned outer ring profile, a deliberate design element that mitigates edge loading. By distributing contact stresses more evenly across the roller path, this crowning dramatically extends service life and prevents premature failure, even in systems experiencing significant misalignment or moment loads. For environments where contamination is a concern, such as in food processing or outdoor machinery, models equipped with seals or a V-ring are available to effectively retain grease and exclude dust, debris, and moisture.

The performance advantages of THK Cam Followers are substantial and directly impact machine efficiency and longevity. Their high rigidity and load capacity, derived from the needle roller construction, allow them to handle heavy radial, axial, and moment loads simultaneously, making them far more robust than standard ball bearings in similar roles. This results in minimal deflection and maintained accuracy over millions of cycles. The low-friction operation of the needle rollers contributes to reduced drive torque and power consumption, while the optimized internal geometry and high-quality steel ensure quiet, low-vibration, and high-speed performance. These attributes collectively translate into reduced maintenance intervals, lower total cost of ownership, and enhanced reliability for the entire mechanical system.

Typical applications for THK Cam Followers are diverse and span critical sectors of industrial automation and precision engineering. In industrial machinery, they are indispensable within high-speed automated assembly lines, transfer systems, and material handling equipment, where they serve as faithful followers for cam plates, providing precise linear or oscillating motion to robotic arms, indexing tables, and pick-and-place units. The automotive industry heavily relies on them in automated welding and painting robots, as well as within engine test stands and transmission assembly jigs, where their durability is paramount. In the realm of precision equipment, THK Cam Followers are found in the intricate mechanisms of semiconductor manufacturing apparatus, printing and packaging machines, and precision measuring instruments, ensuring flawless, repeatable motion where the slightest deviation is unacceptable. Their versatility also extends to specialized applications like construction equipment booms and aircraft landing gear door mechanisms, proving their value wherever robust, guided linear motion is required.

THK Lead Screw Nuts represent a pinnacle of precision motion control, engineered to convert rotational movement into smooth, accurate linear travel with exceptional efficiency and reliability. These components form the heart of lead screw assemblies, featuring precisely machined internal threads that engage with the screw’s helical grooves to deliver controlled motion. Manufactured from high-strength materials such as carbon steel, stainless steel, or engineering plastics, THK nuts are designed to withstand rigorous operational demands while minimizing backlash and wear. Key technical features include advanced thread profiles like trapezoidal or ball screw designs, integrated pre-load mechanisms to eliminate play, and optional self-lubricating properties for maintenance-free operation. Many variants incorporate sealing systems to exclude contaminants, ensuring longevity in harsh environments.

Performance advantages of THK Lead Screw Nuts are rooted in their ability to provide high positional accuracy, repeatability, and torque efficiency. The precision-ground threads ensure minimal friction, reducing energy consumption and heat generation during operation. With backlash compensation through adjustable pre-load, these nuts maintain consistent contact with the screw, eliminating lost motion and enhancing system rigidity. This results in smoother acceleration profiles, reduced vibration, and quieter performance compared to conventional acme thread systems. Durability is another hallmark, with hardened surfaces and corrosion-resistant treatments extending service life even under high-load conditions. Their compact design allows for seamless integration into space-constrained applications without sacrificing payload capacity or speed capabilities.

In industrial machinery, THK Lead Screw Nuts are indispensable for CNC machining centers, where they drive tool positioning slides and workpiece tables with micron-level precision. They enable automated production lines in packaging and material handling equipment, facilitating precise product placement and transfer operations. Automotive systems leverage these nuts in electric power steering mechanisms for accurate rack-and-pinion control, as well as in robotic welding arms and assembly jigs that require repeatable linear motion. Precision equipment applications include medical devices like MRI scanner beds and surgical robots, where silent, jerk-free movement is critical. They also feature in optical positioning stages for semiconductor manufacturing and coordinate measuring machines, ensuring sub-micron accuracy during inspection processes. By combining robust construction with refined motion characteristics, THK Lead Screw Nuts deliver the reliability needed for demanding applications across these sectors, supporting enhanced productivity and operational consistency.

The THK Change Nut represents a significant advancement in recirculating ball screw technology, designed for applications demanding high precision, exceptional repeatability, and minimal axial clearance. This specialized nut is engineered to eliminate backlash, a critical parameter defined as the axial displacement between the screw shaft and the nut under zero load. The core of its design lies in a unique, pre-loaded double-nut configuration. Two single nuts are assembled together with a spacer that creates a precise preload, effectively pressing the ball tracks within each nut against the screw shaft's flanks in opposite directions. This action cancels out any potential dead zone, ensuring immediate and precise response to rotational input without any lost motion. The construction often utilizes high-grade carbon chromium bearing steel, heat-treated to achieve superior hardness and long-term dimensional stability, while the precision-ground balls provide smooth, low-friction motion.

Key technical features that define its performance include its adjustable preload mechanism, which allows for fine-tuning to achieve near-zero backlash, a critical factor for positional accuracy. The nut is designed for optimal ball recirculation, minimizing vibration and noise even at high speeds. Its compact and rigid design ensures high stiffness, capable of withstanding significant axial loads and moments. The performance advantages are substantial, translating directly into enhanced machining quality, improved surface finishes on workpieces, and superior contouring accuracy in CNC applications. By eliminating backlash, the system exhibits exceptional responsiveness and control, which is paramount for high-speed, high-acceleration cycles. This results in reduced cycle times, higher throughput, and improved overall equipment efficiency. Furthermore, the robust construction and high load capacity contribute to extended service life and reduced maintenance requirements, even in demanding operating environments.

Typical applications for the THK Change Nut are found wherever uncompromising precision and rigidity are non-negotiable. In industrial machinery, it is indispensable for high-performance CNC machining centers, where it drives axes in milling, turning, and grinding operations, ensuring the accurate reproduction of complex geometries. It is equally critical in precision assembly robots and pick-and-place systems, where repeatable positioning is essential for product quality. Within the automotive manufacturing sector, these components are integral to automated welding arms, precision laser cutting systems for body panels, and high-speed transfer lines for engine component machining. In the realm of precision equipment, the THK Change Nut is a cornerstone technology for semiconductor manufacturing apparatus, including wafer steppers and wire bonders, where movements measured in microns are standard. It is also vital in precision optical positioning systems, medical device manufacturing equipment, and coordinate measuring machines (CMMs), where its ability to maintain accuracy under varying loads ensures reliable and trustworthy measurement and production outcomes.

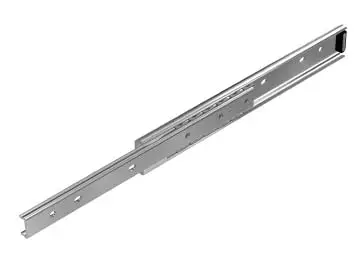

THK Slide Rail systems represent the pinnacle of precision linear motion technology, engineered to deliver unparalleled accuracy, rigidity, and longevity in demanding industrial applications. These systems consist of a high-strength rail and a matching slide block equipped with recirculating ball or roller elements, facilitating smooth, low-friction linear movement along a precisely machined path. The core of their performance lies in THK's proprietary LM guide technology, which ensures minimal deflection and exceptional load capacity across all directions—radial, reverse-radial, and lateral. This robust construction is further enhanced by advanced sealing mechanisms that effectively exclude contaminants like dust, chips, and moisture, while efficiently retaining lubrication to maintain optimal performance in harsh environments.

Key technical features include the incorporation of THK's unique Gothic arch geometry in the raceway design, which provides four-point contact for superior load distribution and smoother motion characteristics. Many models feature integrated pre-load adjustments, allowing for the elimination of internal clearance and enhancing system stiffness for applications requiring high positional accuracy. The rails are manufactured from high-carbon chromium bearing steel, heat-treated to achieve a surface hardness of 58-64 HRC, ensuring exceptional wear resistance and dimensional stability. For corrosive environments, stainless steel variants are available. The slide blocks are precision-ground to micron-level tolerances, guaranteeing seamless integration with the rail and consistent, repeatable motion.

The performance advantages of THK Slide Rails are substantial. They exhibit extremely low coefficients of friction, which translates to reduced power consumption for driving mechanisms and minimal heat generation. Their high rigidity allows for higher operating speeds and accelerations without sacrificing precision, while their damping characteristics contribute to reduced vibration and quieter operation. The design ensures a long service life, even under continuous heavy loads, significantly reducing maintenance requirements and total cost of ownership. Their compact cross-sectional profile allows for space-saving machine designs without compromising on load capacity or travel accuracy.

Typical applications for THK Slide Rails are widespread across critical industries. In industrial machinery, they are indispensable in CNC machining centers for tool changer arms, in semiconductor manufacturing equipment for wafer handling robots, and in injection molding machines for ejector mechanisms. Within automotive production systems, they guide laser welding heads, position robotic arms for assembly tasks, and actuate precision testing apparatus. In the realm of precision equipment, these slide rails are fundamental components in medical devices such as MRI and CT scanner beds, in optical inspection systems for precise stage movement, and in coordinate measuring machines (CMMs) where nanometer-level accuracy is paramount. Their reliability and precision make them the preferred choice for engineers designing automated systems where consistent, dependable linear motion is non-negotiable.

THK Slide Pack represents a comprehensive linear motion solution engineered for seamless integration and exceptional performance in demanding industrial applications. This pre-assembled unit combines THK’s precision LM guides, high-rigidity ball screws, and compact support units into a single, ready-to-install package. Designed to eliminate the complexities of individual component alignment and assembly, the Slide Pack ensures optimal performance from the moment it is mounted, reducing installation time and potential errors. The system features advanced sealing mechanisms that provide robust protection against contaminants such as dust, chips, and moisture, making it suitable for harsh environments. With precision-ground raceways and high-quality steel balls, the Slide Pack delivers smooth, low-friction motion, minimizing wear and extending service life.

Key technical features include high load capacity, achieved through optimized rail and block designs that distribute forces evenly across multiple contact points. The incorporation of THK’s Caged Ball technology in some models prevents ball-to-ball contact, reducing heat generation and noise while maintaining lubrication efficiency. Pre-loaded ball screws ensure minimal backlash and high positional accuracy, critical for applications requiring repeatable precision. The Slide Pack’s compact design maximizes space utilization without compromising performance, and its modular nature allows for customization in stroke length and mounting configurations. Additionally, the system is compatible with various lubrication options, including grease and oil, to suit specific operational needs.

Performance advantages of the THK Slide Pack are evident in its reliability, durability, and efficiency. The pre-assembled nature guarantees proper alignment, which enhances motion smoothness and reduces vibration, leading to improved machining quality and product consistency. Its high rigidity and accuracy contribute to faster cycle times and increased throughput in automated processes. The robust sealing extends maintenance intervals by protecting internal components from debris and corrosion, lowering total cost of ownership. Energy efficiency is another benefit, as the low-friction design reduces power consumption and operational costs over time.

Typical applications span across multiple industries, leveraging the Slide Pack’s versatility and precision. In industrial machinery, it is commonly used in CNC machining centers for tool positioning, automated assembly lines for part handling, and packaging equipment for precise material transfer. Within automotive systems, the Slide Pack facilitates operations in robotic welding arms, engine component testing rigs, and brake system assembly lines, where high loads and accuracy are paramount. In precision equipment, it finds use in semiconductor manufacturing for wafer handling stages, medical devices for imaging system adjustments, and optical instrument positioning, ensuring micron-level accuracy and stability. By integrating the THK Slide Pack, manufacturers achieve enhanced productivity, reduced downtime, and superior performance in their motion control applications.

THK Spline Nuts represent a specialized class of linear motion components engineered for applications demanding the simultaneous transmission of torque and linear motion with exceptional precision and rigidity. These nuts are designed to engage with spline shafts, featuring internal grooves that mesh perfectly with the corresponding teeth on the shaft. This unique coupling mechanism allows the nut to slide smoothly along the shaft's axis while being locked rotationally, enabling it to withstand significant torsional loads and moments without backlash. The fundamental principle involves the precise geometry of the spline profile, which ensures a large contact area between the nut and shaft, distributing loads evenly and enhancing overall system stability.

Key technical features of THK Spline Nuts include their high torque capacity and rigidity, achieved through advanced manufacturing techniques that guarantee precise tooth form accuracy and minimal clearance. Many models incorporate a crowned spline profile or optimized lead to prevent edge loading and ensure smooth, consistent motion across the entire travel length. The nuts are typically manufactured from high-carbon chromium bearing steel, hardened and ground to provide superior wear resistance and long-term dimensional stability. To further enhance performance and service life, options such as seals and shields are available to protect the critical spline engagement from contaminants like dust, chips, and moisture, making them suitable for harsh operating environments.

The performance advantages of integrating THK Spline Nuts into a motion system are substantial. Their primary benefit is the ability to handle complex load conditions, combining high thrust, radial, and moment loads in a single, compact unit. This eliminates the need for separate torque transmission devices, simplifying machine design, reducing the number of components, and saving valuable space. The rigid construction and precise meshing result in highly accurate, repeatable linear positioning with virtually no angular play, which is critical for maintaining precision in automated processes. Furthermore, their robust design ensures high durability and reliability, leading to reduced maintenance requirements and lower total cost of ownership over the system's lifecycle.

Typical applications for THK Spline Nuts are found wherever precise linear movement must be coupled with the transmission of rotational force. In industrial machinery, they are indispensable in the rotary tables of machining centers, where they provide both the vertical support for the table and the means to rotate it accurately for multi-sided machining. Within automotive manufacturing systems, these nuts are employed in robotic welding and assembly arms, enabling the precise positioning of heavy tools while managing the reactive torques generated during operation. In the realm of precision equipment, they are critical components in semiconductor manufacturing apparatus, such as wafer handling robots, and in various inspection and measuring machines, where their high rigidity and accuracy ensure flawless performance in sensitive, high-throughput processes.

THK Precision Linear Packs represent a fully integrated linear motion solution, combining high-precision LM Guides, precision-ground ball screws, support units, and a rigid aluminum housing into a single, compact, and easily installable unit. This pre-assembled system is engineered to deliver exceptional performance in applications demanding high rigidity, smooth motion, and precise positioning. The core of its design lies in the integration of THK's proprietary LM Guide technology, which utilizes a recirculating ball bearing system within a Gothic arch groove configuration. This design ensures high load capacity in all directions—radial, reverse-radial, and lateral—while providing outstanding accuracy and minimal friction.

Key technical features define the performance envelope of the Precision Linear Pack. The system incorporates Caged Ball technology within the LM Guide, which separates the rolling elements with a precision retainer. This design drastically reduces friction, minimizes heat generation, and eliminates ball-to-ball contact, leading to a smoother, quieter operation and an exceptionally long service life even under high-speed reciprocating motion. The integrated precision ball screws are manufactured to high accuracy grades, ensuring minimal cumulative pitch error for repeatable and highly precise linear positioning. The entire assembly is sealed with high-performance wipers and seals to protect the critical rolling elements from dust, chips, and other contaminants, making it highly reliable in demanding industrial environments.

The performance advantages of this integrated approach are significant for machine builders and automation engineers. By providing a single, pre-aligned unit, the Precision Linear Pack dramatically reduces design complexity and assembly time. It eliminates the need for time-consuming and skill-dependent on-site alignment of individual components like the guide, screw, and support bearings. This not only accelerates machine build cycles but also guarantees optimal performance from the outset, as the system's inherent accuracy is preserved. The compact, space-saving design allows for more efficient machine layouts, while the high rigidity ensures minimal deflection under load, which is critical for maintaining precision during machining, measuring, or assembly operations. The low-friction, caged ball design contributes to higher efficiency, allowing for the use of smaller, more cost-effective motors and drives.

Typical applications for the THK Precision Linear Pack are found wherever robust and precise linear motion is paramount. In industrial machinery, they are extensively used in the axes of CNC machining centers, EDM machines, and precision grinding equipment for accurate tool or workpiece positioning. Within automotive manufacturing systems, these packs are integral to automated welding robots, precision assembly stations, and high-speed material handling gantries. In the realm of precision equipment, they provide the critical motion for semiconductor wafer handling robots, coordinate measuring machines (CMMs), and advanced optical inspection systems. Their sealed and robust construction makes them equally suitable for applications in food and packaging machinery, where resistance to washdowns and particulate contamination is essential.

THK Cross Roller Guides represent a pinnacle of precision linear motion technology, engineered to deliver exceptional rigidity, accuracy, and smooth operation in demanding applications. At the core of their design are cylindrical rollers arranged in a cross pattern between V-shaped grooves on the guide rail and block. This unique configuration allows the rollers to bear loads from all directions—radial, reverse-radial, and lateral—simultaneously, eliminating the need for complex multi-directional guide combinations. The rollers undergo a meticulous preloading process during assembly, ensuring zero clearance and enhanced stiffness, which is critical for maintaining positional accuracy under varying operational forces.

Key technical features include the use of high-carbon chromium bearing steel for rollers and raceways, heat-treated to achieve a hardness of HRC 58–62, providing superior wear resistance and longevity. The compact, space-saving design integrates the guide and table functions, reducing the overall footprint and simplifying machine construction. Sealing systems, often incorporating specialized grease nipples, protect against contaminants like dust and chips, making these guides suitable for harsh environments. Optional accessories, such as scrapers and seals, further enhance durability in challenging conditions.

Performance advantages are substantial, starting with high rigidity that minimizes elastic deformation under load, crucial for precision machining and measurement tasks. The cross roller arrangement ensures smooth, low-friction motion with minimal rolling resistance, contributing to energy efficiency and reduced heat generation. Accuracy is exceptional, with running parallelism errors controlled to within microns, and repeatability that meets the stringent demands of semiconductor manufacturing, optical alignment systems, and high-speed automation. The guides exhibit minimal maintenance requirements, thanks to their sealed design and long-term lubrication capabilities, which extend service intervals and reduce downtime.

Typical applications span industries where precision and reliability are non-negotiable. In industrial machinery, THK Cross Roller Guides are integral to CNC machining centers, grinding machines, and coordinate measuring machines (CMMs), where they support heavy cutting forces while maintaining tight tolerances. Automotive systems leverage them in robotic welding arms, assembly line transfer units, and engine testing equipment, where high-speed, repetitive motions demand durability and consistency. Precision equipment, such as semiconductor wafer handlers, medical imaging devices, and aerospace instrumentation, relies on these guides for vibration damping, smooth traversal, and sub-micron accuracy. Their versatility also extends to optical systems, including lens positioning stages and telescope mounts, where stability and minimal deflection are paramount. By combining robust construction with refined engineering, THK Cross Roller Guides empower industries to achieve higher productivity, precision, and operational efficiency in even the most challenging environments.

THK Guide Ball Bushing represents a fundamental advancement in linear motion technology, engineered to deliver exceptional precision, reliability, and longevity in demanding industrial environments. At its core, this component is a recirculating ball bushing system that facilitates smooth, low-friction linear movement along a shaft or rail. The design incorporates a series of precision-ground balls that circulate endlessly within a hardened steel bushing, ensuring consistent contact and load distribution. This mechanism minimizes rolling resistance while maximizing load capacity, making it an ideal solution for applications requiring high accuracy and repeatability.

Key technical features distinguish the THK Guide Ball Bushing from conventional linear guides. It boasts a compact, lightweight structure that simplifies integration into space-constrained machinery. The bushing is constructed from high-carbon chromium bearing steel, heat-treated to achieve superior hardness and wear resistance. A critical innovation lies in its retainer design, which prevents ball-to-ball contact, reducing noise, vibration, and the risk of brinelling under high-load conditions. Additionally, the incorporation of seals or shields protects against contaminants like dust, chips, and moisture, extending service life even in harsh operating environments. Optional configurations include open-type, adjustable-diameter, and self-aligning variants to accommodate misalignment and simplify maintenance.

Performance advantages are evident in its operational efficiency and durability. The low coefficient of friction enables high-speed travel with minimal energy consumption, while the high rigidity ensures stable performance under moment loads and varying forces. This results in improved positioning accuracy, often within micrometer tolerances, and enhanced system responsiveness. Maintenance requirements are minimal due to the long-lasting lubrication intervals and corrosion-resistant materials, reducing downtime and total cost of ownership. The bushing's ability to handle combined loads—radial, reverse radial, and moment—makes it versatile for complex motion profiles.

Typical applications span across critical sectors where precision and reliability are paramount. In industrial machinery, THK Guide Ball Bushings are integral to CNC machine tools, robotic arms, and automated assembly systems, facilitating precise linear motion in axes such as X, Y, and Z. Within automotive systems, they contribute to engine testing equipment, brake assembly lines, and suspension component manufacturing, enduring high cycles and dynamic loads. In precision equipment, these bushings are found in semiconductor manufacturing devices, medical imaging systems, and optical positioning stages, where smooth, backlash-free movement is essential for micron-level accuracy. By enabling efficient linear motion with minimal maintenance, THK Guide Ball Bushing supports advancements in automation, productivity, and technological innovation across diverse industries.

THK LM Guide Actuators integrate precision linear motion components into a single, compact unit, combining a high-rigidity LM Guide with a precision ball screw or other drive mechanism to deliver smooth, accurate, and highly reliable linear movement. These actuators are engineered to provide exceptional performance in applications demanding precise positioning, high load capacity, and long-term operational stability. The core of the actuator features THK’s proprietary LM Guide technology, which utilizes a recirculating ball bearing system within a rigid rail and block assembly. This design ensures minimal friction, high stiffness, and excellent resistance to moment loads, enabling the actuator to maintain precision even under challenging conditions. The integrated drive mechanism, typically a precision-ground or rolled ball screw, offers high efficiency and precise control over linear displacement, with options for various lead accuracies to match specific application requirements.

Key technical features include the use of high-grade materials such as hardened steel for rolling elements and corrosion-resistant coatings on critical components, ensuring durability and extended service life. Many models incorporate seals and wipers to protect the internal recirculating balls from contaminants like dust, chips, and moisture, making them suitable for harsh environments. Optional configurations include motor mounts, couplings, and feedback systems for seamless integration with servomotors or stepper motors, facilitating closed-loop control and enhancing positioning accuracy. The compact design minimizes the overall footprint while maximizing travel range and load capacity, allowing for efficient use of space in machinery layouts. Additionally, THK LM Guide Actuators are available in various sizes, preload levels, and accuracy classes to accommodate diverse operational needs, from standard industrial tasks to ultra-precise applications.

Performance advantages are evident in their ability to achieve high-speed operation with minimal vibration and noise, contributing to smoother machine cycles and improved product quality. The low friction characteristics reduce energy consumption and heat generation, while the high rigidity ensures minimal deflection under load, maintaining accuracy during repetitive movements. These actuators excel in applications requiring high positional repeatability, often within microns, and their robust construction minimizes maintenance requirements, leading to reduced downtime and lower total cost of ownership. The combination of high load capacity and compact design allows for the handling of significant forces in confined spaces, enhancing the versatility of the systems they are integrated into.

Typical applications span across industrial machinery, where they are used in CNC machine tools for tool positioning, automated assembly lines for component placement, and packaging equipment for precise material handling. In automotive systems, THK LM Guide Actuators drive processes such as robotic welding, part transfer mechanisms, and testing equipment that demand repeatable motion and high reliability. Within precision equipment, they are essential in semiconductor manufacturing for wafer handling stages, medical devices for diagnostic instrument positioning, and optical systems for lens and mirror alignment. Their adaptability and performance make them a critical component in advancing automation, improving efficiency, and ensuring precision across a wide range of industries.