The THK LM Guide HSR M1VV SERIES represents a specialized evolution in linear motion technology, engineered explicitly for reliable operation in medium to low vacuum environments. This full ball type LM Guide integrates THK's proven recirculating ball design with vacuum-compatible materials and sealing mechanisms, ensuring minimal outgassing and maintaining vacuum integrity down to 10⁻² Pa. The guide incorporates stainless steel components, including the track rails and balls, paired with a cage crafted from vacuum-grade materials to prevent contamination. Advanced sealing systems with low-vapor-pressure lubricants are employed to mitigate particulate generation and gas emission, which are critical factors in vacuum applications. The HSR M1VV maintains the high rigidity and load capacity characteristic of the HSR series, supporting smooth, precise linear motion even under demanding conditions.

Key technical features of the HSR M1VV include its corrosion-resistant construction, which enhances durability in clean or controlled atmospheres. The full ball type design ensures uniform load distribution across all rolling elements, reducing wear and extending service life. Pre-load adjustments are available to eliminate backlash and enhance positional accuracy, making it suitable for applications requiring micron-level precision. The guide's compact profile allows for space-efficient integration into machinery, while its ability to handle high moment loads provides stability in multi-axis systems. Performance advantages are evident in its low friction coefficient, which minimizes heat generation and energy consumption, and its high-speed capability, facilitated by optimized ball circulation that prevents skidding and noise. These attributes contribute to consistent, maintenance-free operation over extended periods, reducing downtime and total cost of ownership.

Typical applications for the HSR M1VV SERIES span industries where vacuum compatibility and precision are paramount. In industrial machinery, it is deployed in semiconductor manufacturing equipment, such as wafer handling robots and lithography stages, where vacuum environments are essential for process purity. Within automotive systems, this guide finds use in testing apparatus for fuel injection components or brake systems that simulate vacuum conditions to validate performance and reliability. In precision equipment, it supports the motion stages of electron microscopes, vacuum deposition systems, and medical device assembly lines, ensuring accurate positioning without compromising vacuum levels. The HSR M1VV's robustness also makes it ideal for scientific instrumentation, such as particle accelerators or space simulation chambers, where failure is not an option. By combining vacuum readiness with THK's legacy of durability and precision, this LM Guide enables advancements in technology-driven fields, fostering innovation in automation, research, and high-value production.

THK's LM Guide (full ball type) High Corrosion Resistance SERIES represents a specialized evolution in linear motion technology, engineered specifically for environments where exposure to corrosive elements would rapidly degrade standard components. These guides incorporate a comprehensive anti-corrosion strategy beginning with material selection; all critical components including the rail, block, balls, and retainers are manufactured from stainless steel. This fundamental choice is enhanced by advanced sealing systems that integrate multiple layers of protection. High-performance seals and special grease are employed to aggressively block the ingress of water, corrosive chemicals, and other particulate contaminants, ensuring the internal recirculating ball mechanism remains isolated from the external environment.

The technical architecture of the full ball type design is central to its performance. It features a circular arc groove form in both the rail and block, creating a larger contact area between the balls and the raceways. This geometry allows the guide to carry loads from all directions—radial, reverse radial, and lateral—with high rigidity and stability. The optimized recirculation system ensures smooth, consistent ball movement, which translates into exceptionally low and stable friction, minimal starting friction, and highly precise linear motion. This results in superior positional accuracy, reduced stick-slip phenomena, and consistent performance over a long service life, even under demanding conditions. The high corrosion resistance does not come at the expense of capability; these guides maintain high load capacities, excellent durability, and high-speed performance.

The performance advantages make this series indispensable in a wide array of demanding applications. In industrial machinery, they are critical for semiconductor manufacturing equipment, chemical processing lines, and food and beverage packaging machines, where frequent washdowns with high-pressure, chemical-laden fluids are standard procedure. The automotive industry utilizes these corrosion-resistant guides in painting and coating robots, assembly systems in humid environments, and testing equipment exposed to saline sprays. Within the realm of precision equipment, they are found in medical devices, laboratory automation, and optical instrument stages, where any particulate generation from component corrosion or unpredictable friction would compromise the entire system's integrity and output quality. By guaranteeing reliable, maintenance-free operation in harsh conditions, the THK High Corrosion Resistance SERIES extends equipment lifespan, reduces downtime, and ensures consistent manufacturing quality.

THK's LM Guide (full ball type) High Temperature series represents a specialized evolution in linear motion technology, engineered to deliver uncompromised precision and durability in thermally demanding environments. These guides incorporate a full ball-type recirculating system where the load-bearing balls make complete contact with the raceways, optimizing stress distribution and load capacity. Constructed from heat-resistant materials, including specially formulated steels and high-temperature stable polymers for retainers and seals, they maintain structural integrity and operational reliability at elevated temperatures up to 150°C, and with selected special components, even higher. The design ensures consistent preload and smooth motion by mitigating thermal expansion effects through precision manufacturing and material selection.

Key technical features include enhanced heat treatment of all critical components to preserve hardness and wear resistance under thermal stress. The full ball contact design maximizes rigidity and moment load capacity, crucial for applications requiring high positional accuracy. Advanced sealing systems, often comprising multi-layered, high-temperature resistant wipers and seals, effectively exclude contaminants like dust, chips, and molten splash while retaining lubricants. Special high-temperature greases are specified to reduce friction and wear, extending service intervals. Options such as corrosion-resistant coatings or stainless steel variants are available for harsh environments involving moisture or chemicals.

Performance advantages are substantial in high-temperature settings. These guides exhibit minimal thermal deformation, ensuring repeatable positioning accuracy critical in automated processes. The robust construction reduces maintenance frequency and downtime, as components resist degradation from prolonged heat exposure. Smooth, low-friction motion is maintained, contributing to energy efficiency and reduced heat generation from the guide itself. Vibration damping characteristics enhance stability in dynamic applications, while the high load capacity allows for compact designs in machinery, saving space and weight.

Typical applications span industries where heat is a constant challenge. In industrial machinery, they are integral to injection molding machines, where platens and ejectors operate near molten plastics; die casting equipment handling hot metals; and packaging machinery with heated sealing stations. Automotive manufacturing relies on them for welding robots in body shops, where ambient temperatures soar, and engine test rigs with exposure to radiant heat. Precision equipment applications include semiconductor manufacturing tools, such as wafer handling robots in high-temperature process chambers, and LCD panel production lines with baking or curing stages. In food processing, they serve in ovens or sterilizers, while in aerospace, they support actuator systems in engine-testing environments. By ensuring reliable linear motion under thermal duress, THK's high-temperature LM Guides enable enhanced productivity, precision, and longevity in the most demanding operational conditions.

The THK LM Guide HMG SERIES represents a significant advancement in linear motion technology, specifically engineered as a full ball type straight and curved guide system. This innovative design integrates seamlessly curved and straight sections into a single, continuous guide rail, enabling smooth and precise motion transitions without the need for complex mechanical linkages or separate components. The HMG SERIES utilizes a full ball recirculation system, where balls circulate through both load-bearing and return paths within the guide block, ensuring consistent contact and minimal friction across straight and curved trajectories. Key technical features include a compact, low-profile structure that saves space in machinery layouts, high rigidity achieved through optimized rail and block geometries, and precision-ground raceways that maintain accuracy even under varying loads. The guide is available in multiple sizes and curvature radii, allowing customization for specific path requirements, and it supports pre-load options to eliminate backlash and enhance positional stability.

Performance advantages of the HMG SERIES make it ideal for demanding applications. Its full ball design distributes loads evenly, resulting in high load capacity and long service life with reduced wear. The smooth transition between straight and curved sections minimizes vibration and noise, contributing to quieter operation and improved product quality in sensitive environments. With low friction coefficients, these guides offer high-speed capability and energy efficiency, reducing power consumption in automated systems. They also exhibit excellent resistance to shock and vibration, ensuring reliability in harsh industrial conditions. Maintenance is simplified due to the sealed design, which incorporates grease reservoirs and protective seals to exclude contaminants like dust and moisture, extending relubrication intervals and downtime.

Typical applications span various high-precision industries. In industrial machinery, the HMG SERIES is employed in automated assembly lines, where its curved guides facilitate part transfer between stations without re-gripping, enhancing throughput in electronics manufacturing or packaging systems. Automotive systems benefit from its use in robotic welding arms and painting robots, where smooth, curved motions improve accuracy and finish quality while withstanding high cycle rates. Precision equipment, such as semiconductor handling devices and medical diagnostic instruments, relies on these guides for their repeatability and minimal deflection, critical in processes like wafer inspection or sample analysis. Additionally, they are found in material handling equipment, where curved paths optimize space in warehouse automation, and in machine tools for complex contouring operations. By combining versatility with robust performance, the THK LM Guide HMG SERIES enables innovative machine designs that boost productivity and precision across diverse sectors.

The THK LM Guide HCR Series represents a full ball type linear motion system engineered for high rigidity and precision in demanding industrial applications. This R Guide configuration features a unique design where recirculating balls make complete contact along all raceway surfaces, creating a robust four-directional equal load capacity. Each guide incorporates THK's patented Gothic arch groove geometry, which provides superior accuracy through optimized ball-to-raceway contact angles. The HCR's construction includes large-diameter balls arranged in high-density patterns within precisely machined tracks, significantly increasing load distribution capabilities while maintaining smooth motion characteristics.

Technical specifications reveal why the HCR Series excels in challenging environments. The full ball contact design delivers exceptional stiffness with rated loads reaching up to 2.5 times conventional linear guides, while maintaining C-class accuracy with running parallelism within 7μm per meter. Special heat-treated alloy steel components provide Rockwell hardness ratings of HRC 58-62, ensuring extended service life even under heavy cutting forces or vibration-intensive operations. The integrated sealing system combines metal scrapers with elastomeric contact seals, effectively preventing contamination from chips, coolant, and other particulate matter common in manufacturing environments. Pre-loaded options eliminate internal clearance, achieving precise positioning repeatability within micrometers.

Performance advantages manifest in multiple operational aspects. The HCR's symmetrical load distribution enables stable movement under complex moment loads, critical for applications experiencing sudden directional changes or uneven forces. Friction coefficients remain exceptionally low (typically μ=0.004-0.006) due to optimized ball circulation and THK's proprietary lubrication system, reducing power consumption and minimizing heat generation during high-speed operation. Noise levels are notably suppressed through precision-ground raceways and specially engineered ball return mechanisms, making these guides suitable for cleanroom or medical equipment applications. Maintenance intervals extend significantly compared to conventional linear motion systems, with relubrication periods exceeding 10,000 km of travel under standard operating conditions.

Industrial implementations span diverse sectors requiring reliable linear motion. In automotive manufacturing, HCR Guides provide the structural backbone for robotic welding arms and precision assembly fixtures, handling repetitive high-impact loads while maintaining alignment accuracy. Semiconductor production equipment utilizes these components in wafer handling robots and photolithography stages where vibration damping and micron-level positioning are paramount. Heavy machinery applications include CNC gantry mills and large-scale material handling systems where the guides' high moment load capacity prevents deflection during heavy cutting operations. Medical device manufacturers incorporate HCR Series guides into MRI positioning systems and surgical robotics, benefiting from their smooth motion and magnetic field compatibility. Even in extreme environments like food processing or chemical plants, the enhanced sealing and corrosion-resistant options ensure reliable performance where washdowns or aggressive substances are present.

The THK LM Guide NSR TBC SERIES represents a significant advancement in linear motion technology, featuring a full ball type design with integrated self-aligning capabilities. This construction ensures optimal contact between the balls and raceways, distributing loads evenly across all rolling elements. The self-aligning function automatically compensates for mounting inaccuracies or base surface irregularities, maintaining smooth motion characteristics without requiring precision machining of mounting surfaces. Manufactured with THK's proprietary materials and heat treatment processes, these guides achieve exceptional hardness and wear resistance while maintaining dimensional stability under varying operational conditions.

Key technical features include a reinforced steel shell structure that provides increased rigidity and load capacity compared to conventional designs. The precision-ground raceways feature optimized groove geometry that minimizes friction while maximizing contact area. Specialized sealing systems with multiple labyrinth and contact seals effectively exclude contaminants while retaining lubrication, making these guides suitable for harsh environments. The recirculation system employs THK's advanced ball circuit design that ensures consistent recirculation without ball-to-ball contact, significantly reducing noise and vibration during operation. Pre-loaded options are available for applications requiring minimal deflection and high positional accuracy.

Performance advantages manifest in several critical areas. The NSR TBC SERIES demonstrates up to 30% higher load capacity than previous generations while maintaining compact dimensions. The self-aligning capability reduces installation time and costs by accommodating alignment errors up to ±0.5 degrees without performance degradation. Low friction coefficients enable higher speeds and accelerations while reducing energy consumption. The optimized ball recirculation system extends service life by eliminating stress concentrations and maintaining consistent lubrication distribution. These guides maintain precision even under complex loading conditions, with running parallelism accuracy within 5μm per 300mm of travel.

In industrial machinery applications, the NSR TBC SERIES finds extensive use in CNC machining centers, where it provides stable guidance for spindle heads and tool changers operating under heavy cutting forces. The self-aligning feature proves particularly valuable in large-scale gantry systems where mounting surface imperfections are common. Automotive manufacturing systems employ these guides in welding robots, transfer lines, and assembly automation equipment where reliability and precision are paramount. The contamination resistance makes them suitable for painting and coating applications where particulate exposure is inevitable.

Precision equipment applications include semiconductor manufacturing apparatus, where the guides facilitate nanometer-level positioning in wafer handling and lithography systems. Medical device manufacturing utilizes these components in automated assembly machines requiring cleanroom compatibility and vibration-free operation. The series' thermal stability ensures consistent performance in laboratory automation equipment subjected to temperature variations. Packaging machinery benefits from the high-speed capabilities and durability in repetitive pick-and-place operations. Measurement and inspection systems leverage the guides' accuracy for coordinate measuring machines and optical comparators, where minimal friction-induced errors are critical for measurement integrity.

THK's LM Guide MX SERIES represents a specialized class of miniature cross roller guides engineered for applications demanding the utmost in precision, rigidity, and compactness. As a full ball type linear motion system, its design is fundamentally optimized for scenarios where space is at a premium but performance cannot be compromised. The defining characteristic of the MX SERIES is its unique crossed-roller configuration, where cylindrical rollers are arranged in a precise 90-degree V-groove cross pattern between the rail and the block. This geometry provides simultaneous load capacity in all directions—radial, reverse-radial, and lateral—effectively eliminating backlash and delivering exceptional moment rigidity.

The technical features of the MX SERIES are tailored for high-performance miniature applications. The use of cylindrical rollers, as opposed to standard balls, results in a significantly larger contact area with the raceways. This design choice dramatically increases load capacity and rigidity while minimizing elastic deformation under stress. The compact, low-profile design is a key feature, allowing for integration into tightly constrained mechanical layouts without sacrificing stroke length or performance. Furthermore, the guide is pre-loaded to ensure high positional accuracy and smooth, non-stick-slip motion, which is critical for precise start-and-stop operations. Many models are designed for easy lubrication and are available with optional seals to protect the critical rolling elements from contaminants like dust and chips, thereby ensuring long-term reliability and consistent performance.

These performance advantages translate directly into superior operational outcomes in demanding sectors. The high rigidity and accuracy make the MX SERIES indispensable in the field of precision equipment. It is commonly found in the delicate stages of semiconductor manufacturing machinery, optical instrument positioning systems, and the assembly arms of precision inspection devices. Within industrial automation, these guides are the preferred solution for compact robotic arms, precision XY tables, and the linear axes of high-speed pick-and-place machines where speed and accuracy are paramount. The automotive industry leverages the MX SERIES in advanced manufacturing and testing equipment, such as the precise fixturing for sensor calibration rigs, components within automated transmission assembly systems, and high-accuracy measuring instruments used for quality control. Its ability to provide stable, friction-free linear motion in a minimal footprint makes it a critical enabler of innovation across fields that push the boundaries of miniaturization and precision.

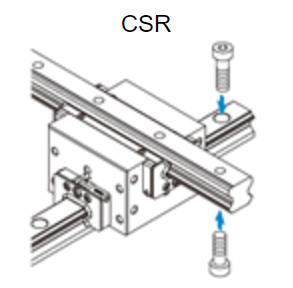

THK's LM Guide CSR SERIES represents a full ball type Cross LM Guide engineered for exceptional rigidity, precision, and load capacity in multi-directional applications. This design incorporates a unique gothic arch groove configuration in both the rail and block, forming a 90-degree contact angle that optimally distributes loads. The full ball complement structure maximizes the number of recirculating balls, significantly enhancing load-bearing capacity and stiffness compared to standard designs. A standout feature is the integrated cross-roller retainer situated between the LM block and rail, which provides additional support against rolling moments and overturning forces, ensuring unparalleled stability under complex loading conditions.

Key technical features include the utilization of large-diameter balls for higher load ratings, a sealed design with integrated scrapers and end seals to prevent contamination from dust, chips, and other particulates, and the availability of a lubricating unit for sustained performance with minimal maintenance. The CSR SERIES is manufactured to precise tolerances, delivering high positional accuracy, smooth motion with minimal friction, and exceptional repeatability. Its compact design saves space while providing superior performance, making it ideal for applications where footprint is a constraint.

Performance advantages are substantial across several metrics. The full ball type construction and cross-roller retainer combine to offer approximately double the rigidity of conventional LM guides, drastically reducing deflection under load. This results in improved machining accuracy, reduced vibration, and enhanced system stability. The high load capacity allows for downsizing of components or handling heavier payloads without compromising service life. Smooth, low-friction motion contributes to higher operational speeds, reduced power consumption, and decreased heat generation, leading to greater overall efficiency and longevity of both the guide and the driven equipment.

Typical applications for the THK CSR SERIES are found in demanding industrial environments. In industrial machinery, it is extensively used in high-precision machine tools, such as machining centers, grinding machines, and milling machines, where rigidity and accuracy are paramount for fine surface finishes and tight tolerances. Within automotive manufacturing systems, these guides are employed in robotic welding arms, precision assembly robots, and transfer lines that require reliable, high-speed operation under significant moment loads. For precision equipment, the CSR SERIES is integral to semiconductor manufacturing apparatus, including wafer handlers and steppers, optical inspection machines, and medical device manufacturing systems where flawless, repeatable motion is critical to product quality and process reliability.

The THK LM Guide JR Series represents a full ball type linear motion system engineered for high rigidity and precision in demanding industrial applications. This structural member rail system features a unique four-row circular arc groove design with a 45° contact angle, creating optimized load distribution across all directions. The JR model incorporates a specially engineered retainer system that prevents ball-to-ball contact, significantly reducing friction and heat generation while maintaining smooth motion characteristics even at high speeds. Its construction utilizes THK's proprietary materials and hardening processes to achieve surface hardness of 58-64 HRC on raceways, ensuring exceptional wear resistance and long service life.

Technical specifications reveal a system capable of handling substantial moment loads while maintaining positioning accuracy. The JR Series demonstrates impressive load ratings, with basic static load ratings reaching up to 1,270 kN and basic dynamic load ratings extending to 680 kN depending on specific model size. The full ball complement design provides approximately 1.7 times higher load capacity compared to standard LM guides, while maintaining low friction coefficients typically ranging from 0.002 to 0.003. This enhanced load capacity combines with precision ground raceways that deliver positioning accuracy within microns, making the system suitable for applications requiring both high stiffness and exact positioning.

Performance advantages extend beyond mere load capacity. The JR Series exhibits exceptional vibration damping characteristics due to its optimized preload adjustment system, which allows for precise control over clearance and stiffness. This results in reduced noise levels during operation and improved surface finish quality in machining applications. The system's sealed design incorporates multiple sealing mechanisms including metal and rubber seals that effectively prevent contamination from dust, chips, and other particulates, maintaining lubrication integrity even in harsh environments. Thermal stability remains consistent across operating temperatures from -20°C to 80°C, ensuring reliable performance in varied industrial conditions.

In industrial machinery applications, the JR Series finds extensive use in heavy-duty machining centers, where its high rigidity supports precise material removal operations on large workpieces. The system's ability to withstand heavy cutting forces while maintaining accuracy makes it ideal for vertical machining centers, boring mills, and large gantry-type machines. Automotive manufacturing systems employ these guides in robotic welding stations, transfer lines, and assembly automation equipment where reliability under continuous operation is paramount. The guides' vibration damping characteristics prove particularly valuable in high-speed pick-and-place systems and automated inspection equipment.

Precision equipment manufacturers utilize the JR Series in semiconductor manufacturing apparatus, LCD panel handling systems, and precision measuring instruments. The system's minimal friction characteristics enable smooth micro-movement capabilities essential in photolithography equipment and wafer inspection machines. Medical device manufacturing leverages these guides in advanced imaging systems and surgical robot positioning mechanisms where absolute reliability and precision are non-negotiable. The combination of high load capacity, precision movement, and contamination resistance establishes the THK LM Guide JR Series as a fundamental component across advanced manufacturing sectors requiring uncompromising performance in linear motion applications.

The THK LM Guide GSR series represents a specialized linear motion solution engineered for applications requiring exceptional radial load capacity and operational stability. This full ball type, separate radial configuration features a unique design where the rail and block can be disassembled, facilitating straightforward installation, maintenance, and replacement in complex machinery layouts. Its construction incorporates a precision-ground raceway with a full ball recirculation system, ensuring smooth, low-friction motion along the entire travel path. The GSR model is characterized by its high rigidity and ability to withstand substantial moments and radial forces, making it suitable for demanding industrial environments where precision and durability are paramount.

Key technical features of the GSR LM Guide include its four-row, two-path ball contact design, which maximizes load distribution and enhances stiffness. The balls are arranged in a radial pattern, optimizing contact angles to handle combined loads effectively. A reinforced seal system with multi-layer contact seals and metal scrapers protects the internal components from contaminants such as dust, chips, and moisture, significantly extending service life even in harsh conditions. Pre-load adjustments are available to minimize deflection under load, ensuring high positional accuracy and repeatability. The guide is manufactured from high-carbon chromium bearing steel, heat-treated to achieve superior hardness and wear resistance, while optional coatings provide additional corrosion protection for challenging environments.

Performance advantages of the GSR series are evident in its ability to maintain precise linear motion under heavy loads and high speeds. The full ball recirculation minimizes vibration and noise, contributing to smoother operation and reduced maintenance intervals. Its high load capacity allows for the downsizing of components in system design, saving space and weight without compromising performance. The separate structure simplifies alignment during assembly, reducing installation time and potential errors. Energy efficiency is improved through low friction coefficients, which also result in less heat generation during continuous operation.

Typical applications for the THK GSR LM Guide span across various sectors, including industrial machinery where it is employed in machining centers for tool positioning, automated assembly lines for precise part handling, and injection molding machines for mold clamping units. In automotive systems, it is utilized in robotic welding arms, precision testing equipment, and transmission assembly jigs. Within precision equipment, the GSR guides are integral to semiconductor manufacturing apparatus, optical alignment systems, and medical device automation, where reliability and accuracy are critical. Its versatility and robust performance make it an ideal choice for engineers seeking to enhance the efficiency and longevity of linear motion systems in challenging applications.

The THK LM Guide HR Series represents a pinnacle of linear motion engineering, featuring a full-ball type, four-way equal load design that delivers exceptional rigidity, precision, and longevity in demanding applications. This model is constructed as a separate type unit, allowing for simplified assembly, maintenance, and alignment adjustments. Its defining characteristic is the incorporation of a full complement of balls arranged in a Gothic arch groove configuration, which contacts the rail at four points. This structure enables the bearing to withstand loads—radial, reverse radial, and lateral—equally in all four directions, providing remarkable stability and moment resistance. The optimized recirculation system ensures smooth, uninterrupted ball movement, minimizing friction and preventing skidding even under high-speed operation or varying load conditions.

Key technical features include the use of high-grade steel for both the rail and block, subjected to THK's proprietary heat treatment processes to achieve superior surface hardness and core toughness, significantly enhancing wear resistance and load capacity. The HR model is available with optional seals and grease fittings, facilitating effective contamination exclusion and simplified re-lubrication, which is critical for maintaining performance in harsh environments. Its precision-ground raceways and strict manufacturing tolerances ensure high running accuracy and smooth motion characteristics, with minimal variation in dynamic torque. The separate design allows for easy preload adjustment, enabling users to fine-tune the assembly to achieve the desired level of rigidity and backlash elimination for specific application requirements.

Performance advantages of the HR Series are substantial, offering high positional accuracy and repeatability, which are essential for precision machining and automation tasks. Its four-way equal load capacity distributes stress evenly, reducing deformation under complex load scenarios and extending service life. The low friction coefficient contributes to energy efficiency, allowing for reduced drive motor sizing and lower operational costs. Additionally, the design minimizes vibration and noise generation, promoting quieter operation and improved workpiece surface finish quality. These attributes make it exceptionally reliable in applications involving high moment loads, frequent start-stop cycles, or continuous high-speed travel.

Typical applications span across various high-performance sectors. In industrial machinery, it is extensively used in machining centers, CNC milling machines, grinding equipment, and industrial robots where high rigidity and precision are non-negotiable. Within automotive manufacturing systems, the HR Guide is employed in precision assembly robots, transfer lines, and automated welding equipment that demand durability under heavy loads and high cycle rates. In the realm of precision equipment, it finds use in semiconductor manufacturing apparatus, optical positioning stages, and coordinate measuring machines that require ultra-smooth motion and minimal error. Its robust design and versatile performance characteristics make the THK LM Guide HR Series an optimal solution for advancing productivity and accuracy in modern automated and precision-driven industries.

THK’s LM Guide LM Guide (full ball type) with its anti-ball-dropout design, particularly in the miniature Model RSX series, represents a compact yet highly reliable linear motion solution engineered for precision applications where space constraints and operational integrity are critical. This guide incorporates a full ball-type recirculating system, where balls circulate smoothly along the raceway, ensuring consistent load distribution and minimal friction. A key feature is the specialized end cap and retainer mechanism that prevents balls from falling out during handling or assembly, even when the guide block is detached from the rail. This anti-dropout capability simplifies maintenance, reduces the risk of contamination, and enhances overall system durability, making it ideal for environments requiring frequent disassembly or vertical mounting.

Technically, the Model RSX miniature LM Guide boasts a compact cross-section and lightweight design, enabling integration into tight spaces without sacrificing performance. It utilizes THK’s precision-ground raceways and high-grade steel balls, which contribute to high rigidity, excellent accuracy, and smooth motion. The full ball contact design maximizes load capacity in all directions—radial, reverse-radial, and lateral—while maintaining low noise and vibration levels. Additionally, the guide features optimized grease retention and optional seals for enhanced dust and debris resistance, prolonging service life in demanding conditions. Performance advantages include superior positioning repeatability, reduced maintenance downtime due to the anti-ball-dropout feature, and energy efficiency from low rolling resistance. These attributes translate into extended operational life and consistent performance under high-speed or high-frequency cycling.

Typical applications span industries where precision, reliability, and compactness are paramount. In industrial machinery, the Model RSX is commonly used in semiconductor manufacturing equipment, PCB drilling machines, and automated assembly systems, where its miniature size and anti-dropout design facilitate precise component placement and reduce machine setup time. In automotive systems, it integrates into robotic welding arms, inspection devices, and transmission testing fixtures, offering vibration damping and durability for high-cycle operations. For precision equipment, such as medical devices (e.g., MRI scanners and lab automation) or optical instruments, the guide’s smooth motion and accuracy ensure stable, repeatable movements critical to sensitive processes. Overall, THK’s miniature LM Guide Model RSX delivers a robust, space-saving solution that enhances efficiency and reliability across diverse automated and precision-driven fields.

THK's LM Guide LM Guide (full ball type) Miniature Model SRS G represents a pinnacle of compact linear motion technology, engineered for applications where space constraints and precision are paramount. This miniature guide incorporates a full-ball type design, where the recirculating balls make complete contact with the raceways, ensuring uniform load distribution and enhanced rigidity. The SRS G model features a compact cross-section with a low profile, making it ideal for integration into tight spaces without compromising performance. Constructed from high-carbon chromium bearing steel, the rails and blocks are heat-treated to achieve a surface hardness of HRC 58 or higher, providing exceptional wear resistance and longevity. The guide is pre-loaded to eliminate internal clearance, delivering high positional accuracy and smooth, precise motion with minimal friction.

Key technical features include the use of high-grade stainless steel for corrosion resistance in harsh environments, along with precision-ground raceways that optimize ball recirculation for consistent performance. The SRS G model employs a compact ball retainer system that prevents ball-to-ball contact, reducing noise and vibration during operation. Its sealed design incorporates wipers and seals to protect against contaminants like dust and debris, extending service life in demanding conditions. The guide supports high load capacities in all directions—radial, reverse-radial, and lateral—thanks to its optimized groove geometry and full-ball contact structure. With a focus on miniaturization, it maintains high stiffness and accuracy while reducing overall weight, which is critical for dynamic applications.

Performance advantages of the SRS G Miniature Model include exceptional smoothness and low friction, achieved through the full-ball recirculation system that minimizes resistance and energy consumption. This results in higher efficiency and reduced heat generation, contributing to longer operational life. The guide's high rigidity and pre-loading ensure minimal deflection under load, enabling precise positioning and repeatability essential for automated systems. Its compact size allows for faster acceleration and deceleration in motion cycles, improving throughput in high-speed applications. Additionally, the corrosion-resistant materials and sealing mechanisms reduce maintenance requirements, making it a reliable choice for continuous operation in industrial settings.

Typical applications span across industrial machinery, automotive systems, and precision equipment where space-saving and accuracy are critical. In industrial automation, the SRS G is commonly used in compact CNC machining centers, pick-and-place robots, and semiconductor manufacturing equipment for precise component positioning. In the automotive sector, it integrates into assembly line robots, engine part handlers, and testing instruments that demand high-speed, low-friction motion. For precision equipment, it finds use in medical devices like diagnostic scanners and surgical robots, as well as in optical alignment systems and measuring instruments where minimal vibration and high repeatability are essential. Its versatility and reliability make it a go-to solution for advancing efficiency in modern, miniaturized engineering environments.

THK's LM Guide RSR series represents a significant advancement in compact linear motion technology, engineered specifically for applications where space constraints and precision are paramount. As a miniature full-ball type linear guide, the RSR model incorporates a complete ball recirculation system within an exceptionally slim and lightweight profile. The design features two rows of load-carrying balls arranged in a Gothic arch groove configuration, ensuring optimal load distribution and smooth motion characteristics. With standardized rail widths starting from 3mm and varying lengths to accommodate different stroke requirements, this series maintains the fundamental principles of THK's LM Guide technology while achieving remarkable miniaturization.

The technical features of the RSR series demonstrate sophisticated engineering solutions for compact applications. The full-ball recirculation system employs a unique end cap design that facilitates seamless ball circulation even in miniature dimensions, preventing ball dropout during operation. The Gothic arch groove geometry provides four-point contact for each ball, delivering high rigidity and precise motion guidance. Special seals integrated into the slider effectively prevent contamination from dust and debris while retaining lubrication, crucial for maintaining performance in demanding environments. The series offers various accuracy classes, with high-precision versions achieving running parallelism errors as low as 7μm per meter.

Performance advantages of the RSR miniature guide stem from its optimized structural design and manufacturing precision. The compact dimensions enable direct integration into tight spaces without compromising load capacity or motion accuracy. Despite its miniature size, the RSR maintains impressive load ratings, with basic static load ratings reaching 1.96 kN and basic dynamic load ratings up to 1.47 kN depending on the specific model. The low friction coefficient, typically below 0.005, ensures smooth motion with minimal resistance, contributing to precise positioning and reduced drive power requirements. The design's high rigidity minimizes deflection under load, maintaining accuracy during operation. These characteristics combine to deliver exceptional motion smoothness, positioning repeatability within microns, and long service life even in high-cycle applications.

Typical applications for the RSR series span multiple industries where compact, precise linear motion is essential. In industrial automation, these guides are extensively used in small assembly robots, precision pick-and-place units, and miniature linear actuators. The semiconductor manufacturing industry employs RSR guides in wafer handling equipment, chip mounting systems, and inspection apparatus where cleanroom compatibility and minimal particle generation are critical. Medical equipment manufacturers integrate these miniature guides into diagnostic instruments, laboratory automation systems, and surgical devices requiring precise, reliable motion in confined spaces. The automotive sector utilizes RSR guides in electronic throttle control systems, sensor positioning mechanisms, and advanced driver-assistance system components. Additionally, precision measurement equipment, optical positioning systems, and electronic component manufacturing machinery benefit from the RSR's combination of compact dimensions and high-performance characteristics, enabling the development of increasingly sophisticated equipment with enhanced capabilities and reduced footprints.

The THK LM Guide HRW series represents a robust linear motion solution engineered for applications demanding exceptional rigidity and load capacity. Characterized by its wide rail design and full-ball type recirculation system, this guide incorporates four raceway tracks with a Gothic arch geometry that provides consistent contact points between the balls and raceways. This configuration ensures high rigidity in all directions—radial, reverse-radial, and lateral—while maintaining smooth, precise motion. The HRW's construction features a large contact area between the rail and block, distributing loads evenly across a broader surface to minimize deformation under heavy or moment loads. Its enhanced sealing system includes multi-layer scrapers and end seals that effectively exclude contaminants like dust, chips, and moisture, making it suitable for harsh environments.

Performance advantages of the HRW series stem directly from its design. The full-ball type recirculation allows for a higher ball count and optimized contact angles, significantly increasing load ratings—both dynamic and static—compared to standard LM guides. This results in a longer service life and reduced maintenance intervals, even under demanding operating conditions. The wide rail profile provides superior stability, effectively resisting overturning moments and vibration, which is critical for maintaining accuracy in precision applications. Low noise operation and reduced vibration transmission contribute to improved performance in sensitive equipment. Additionally, the HRW offers excellent positioning accuracy and repeatability, with minimal friction variation, ensuring consistent performance across its travel length.

Typical applications leverage the HRW's strength and precision across various industries. In industrial machinery, it is commonly deployed in heavy-duty machining centers, where it supports high-load spindles and tables subjected to significant cutting forces. The automotive industry utilizes these guides in welding robots, assembly line transporters, and press automation equipment, where durability and reliability under cyclic loading are paramount. For precision equipment, the HRW finds use in semiconductor manufacturing apparatus, such as wafer handling robots and inspection stages, where its vibration damping and smooth motion are essential for micron-level accuracy. Other applications include large-scale measuring instruments, medical device manufacturing systems, and packaging machinery requiring robust linear guidance for heavy loads and long-term, maintenance-free operation.

THK's LM Guide NRS X series represents a significant advancement in linear motion technology, specifically engineered for ultra-heavy load applications where exceptional rigidity, precision, and longevity are non-negotiable. This full-ball type, 4-way equal load design features a unique structure where the ball rolling elements make contact at four points—two on the raceway and two on the side—ensuring uniform stress distribution and superior load capacity in all directions: radial, reverse-radial, and lateral. The recirculation system is meticulously designed to facilitate smooth, uninterrupted ball movement, even under extreme forces, minimizing friction and preventing skewing or jamming. Constructed from high-grade steel and subjected to THK's proprietary heat treatment and precision grinding processes, the LM Guide NRS X achieves remarkable surface hardness and dimensional accuracy, contributing to its exceptional wear resistance and consistent performance over extended operational lifetimes.

Key technical features include an optimized ball groove profile that maximizes contact area, significantly enhancing moment load tolerance and stiffness. The incorporation of a high-capacity, multi-circuit ball recirculation mechanism ensures stable motion without speed limitations, while advanced sealing technologies protect against contaminants like dust, chips, and moisture, maintaining lubrication integrity in harsh environments. Pre-load adjustment options allow for fine-tuning to eliminate backlash, delivering unparalleled positioning accuracy and repeatability. Performance advantages are substantial: the NRS X can withstand dynamic load ratings exceeding conventional models by up to 40%, with a static load capacity that supports massive weights without deformation. Its high rigidity minimizes deflection under load, critical for maintaining precision in heavy-duty operations, while the low coefficient of friction reduces energy consumption and heat generation, enabling higher speeds and accelerations without compromising service life.

Typical applications span industries requiring robust linear motion solutions under demanding conditions. In industrial machinery, the NRS X is integral to heavy-duty machining centers, where it guides spindle heads and tables supporting large workpieces, ensuring micron-level accuracy during milling, drilling, and grinding operations. It is also deployed in injection molding machines, handling high clamping forces with smooth, repeatable strokes that enhance part quality and cycle times. Within automotive systems, this model is found in automated welding lines, robotic arms assembling chassis components, and press machines forming body panels, where its ability to endure shock loads and vibrations guarantees reliability in high-throughput production environments. For precision equipment, the NRS X serves in semiconductor manufacturing apparatus, such as wafer handling robots and lithography stages, where its stability and minimal thermal expansion maintain sub-micron alignment under continuous use. Additionally, it supports heavy-duty measuring instruments and optical alignment systems in aerospace and defense applications, where precision and durability are paramount. By combining ultra-heavy load capability with refined motion control, the THK LM Guide NRS X empowers engineers to push the boundaries of efficiency and accuracy in the most challenging settings.

The THK LM Guide NR X series represents a significant advancement in linear motion technology, specifically engineered to manage ultra-heavy loads with exceptional stability and precision. As a full ball type, radial configuration LM Guide, this model is distinguished by its robust construction and optimized recirculating ball mechanism. The guide incorporates a large number of load-carrying balls arranged in a radial pattern, which are precisely preloaded to eliminate internal clearance. This design ensures high rigidity and minimal deflection, even under extreme operational stresses. The raceway geometry is meticulously machined to provide four-point contact for each ball, distributing loads evenly and enhancing moment capacity. Components are manufactured from high-carbon chromium bearing steel, subjected to rigorous heat treatment processes to achieve superior surface hardness and core toughness, thereby extending service life under demanding conditions.

Key technical features include an advanced sealing system comprising multi-lip seals and scrapers that effectively exclude contaminants like dust, chips, and moisture, while retaining lubrication for consistent performance in harsh environments. The NR X model also integrates a crowning profile on the raceways to mitigate edge stress concentrations, preventing premature wear and ensuring smooth motion over the entire stroke. Its compact design allows for space-saving integration without compromising load capacity, making it ideal for applications where footprint constraints coexist with heavy-duty requirements. Performance advantages are substantial; the guide offers remarkably low friction coefficients, reducing energy consumption and heat generation during high-speed operations. Its high positional accuracy and repeatability are maintained across varying temperatures and loads, thanks to the thermal stability of its materials and precision grinding of all contact surfaces. The NR X excels in damping vibrations, contributing to quieter operation and protecting sensitive machinery from dynamic disturbances.

Typical applications span critical sectors where reliability under heavy loads is non-negotiable. In industrial machinery, the NR X is deployed in large-scale machining centers, heavy-duty CNC lathes, and press feeds, where it supports massive workpieces and cutting forces while maintaining alignment integrity. Within automotive systems, it finds use in robotic welding arms, assembly line transporters, and stamping press rams, enduring cyclical impacts and high inertial loads without degradation. For precision equipment, this guide is utilized in semiconductor manufacturing apparatus, such as wafer handling robots and lithography stages, where ultra-smooth motion and minimal particle generation are essential. Additionally, it serves in aerospace testing rigs and large-scale metrology instruments, providing steadfast guidance under variable orientations and prolonged use. The THK LM Guide NR X series thus stands as a cornerstone for engineers seeking to enhance machine durability, efficiency, and accuracy in the most challenging operational contexts.

THK's LM Guide SR Series represents a radial-type linear motion system employing a full-ball contact design that delivers exceptional rigidity, precision, and load capacity in compact dimensions. This configuration features a rail and block arrangement where the rolling elements—precision-ground steel balls—are recirculated through a compact, optimized circuit. The SR model’s defining radial geometry positions the balls to contact the raceways at a specific angular arrangement, distributing loads evenly and enhancing moment resistance. This design inherently supports applications requiring high stiffness and smooth, low-friction linear travel, even under substantial external forces or complex multi-directional loading scenarios.

Key technical features of the SR LM Guide include its four-row, full-ball construction, which maximizes the number of load-bearing balls in contact with the raceway. This significantly increases rigidity and load capacity compared to designs with fewer rows or different contact angles. The balls are meticulously sized and arranged to minimize elastic deformation under load, contributing to highly repeatable positioning accuracy. A robust, precision-formed end seal and scraper are integrated to prevent contamination from dust, chips, or other particulates, while a highly efficient grease retention system ensures long-term lubrication and consistent performance. The compact cross-section of the SR block is a notable advantage, allowing for space-saving machine designs without compromising on performance or durability.

The performance advantages derived from this engineering are substantial. The high rigidity directly translates to reduced deflection and vibration under load, enabling higher machining accuracy, improved surface finishes in manufacturing processes, and enhanced dynamic response in automated systems. The low friction coefficient ensures smooth, precise movement with minimal stick-slip, which is critical for applications involving fine incremental positioning or high-speed reciprocation. Furthermore, the optimized recirculation system and high-quality materials contribute to a long service life and consistent operation, even in demanding, high-cycle environments. This reliability reduces maintenance requirements and total cost of ownership over the system's lifespan.

Typical applications for the THK LM Guide SR are found across industries where precision, reliability, and compactness are paramount. In industrial machinery, it is extensively used in the slides of CNC machining centers, grinding machines, and precision milling equipment, where it provides the stable and accurate guidance necessary for tight-tolerance manufacturing. Within automotive production systems, the SR guide is employed in robotic welding arms, precision assembly jigs, and automated material handling equipment, handling high moment loads and ensuring repeatable positioning. In the realm of precision equipment, it serves as a critical component in semiconductor manufacturing apparatus, optical positioning stages, and coordinate measuring machines (CMMs), where its minimal friction and high accuracy are essential for micron-level precision and long-term operational stability.

The THK LM Guide HSR series represents a globally standardized linear motion solution engineered for precision and durability in demanding industrial applications. As a full ball type linear guide, it incorporates a unique four-row circular arc groove design with a 45-degree contact angle, creating optimized load distribution across all directions. Each LM block contains precisely arranged recirculating balls that circulate endlessly through the load zones and return paths, ensuring smooth motion with minimal friction fluctuations. The HSR's compact yet robust structure features integrated seals at both ends—including metal scrapers and grease-resistant seals—that effectively prevent contamination from dust, chips, and other particulate matter while retaining lubrication for extended service intervals.

Technical superiority defines the HSR series through its exceptional rigidity and load capacity. The four-directional equal load characteristic allows the guide to handle radial, reverse-radial, and lateral loads simultaneously with high moment resistance, making it exceptionally stable under complex force conditions. Precision grinding of all critical surfaces ensures consistent accuracy and smooth rolling motion, while the optimized ball groove geometry minimizes elastic deformation under load. These guides achieve remarkable positioning precision with running parallelism errors controlled within strict tolerances, backed by THK's proprietary C1-C5 clearance grades that allow precise preload adjustment for specific application requirements. The standardized dimensions ensure full interchangeability across global markets, simplifying maintenance and replacement procedures.

Performance advantages manifest in several critical areas that directly impact operational efficiency. The HSR demonstrates significantly lower friction coefficients compared to conventional sliding mechanisms, reducing power consumption by up to 90% while enabling higher speeds and accelerations. Its maintenance-free operation eliminates periodic adjustment needs, and the effective sealing system ensures reliable performance even in contaminated environments. The guide's high rigidity translates to minimal deflection under load, maintaining accuracy throughout the stroke length while damping vibrations that could compromise machining quality or measurement precision. With noise levels substantially reduced compared to alternative linear motion systems, the HSR creates quieter working environments suitable for precision manufacturing facilities and laboratory settings.

Industrial applications span diverse sectors where precision linear motion is paramount. In automated manufacturing systems, HSR guides provide the foundation for high-speed machining centers, CNC equipment positioning tables, and industrial robot seventh-axis traverse mechanisms. The automotive industry utilizes these components in automated welding guns, precision assembly robots, and testing equipment requiring repeatable linear motion. Semiconductor manufacturing equipment relies on HSR guides for wafer handling robots, stepper stages, and inspection systems where sub-micron precision is essential. Additional applications include precision measuring instruments, medical device manufacturing equipment, electronic component assembly systems, and packaging machinery where smooth, accurate linear motion directly impacts product quality and production throughput. The global standardization of the HSR series ensures consistent performance and availability across these diverse applications worldwide.